Infiniti QX56 (JA60). Manual - part 675

OIL FILTER

LU-11

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

OIL FILTER

Removal and Installation

INFOID:0000000005149027

REMOVAL

1. Drain the engine oil. Refer to

.

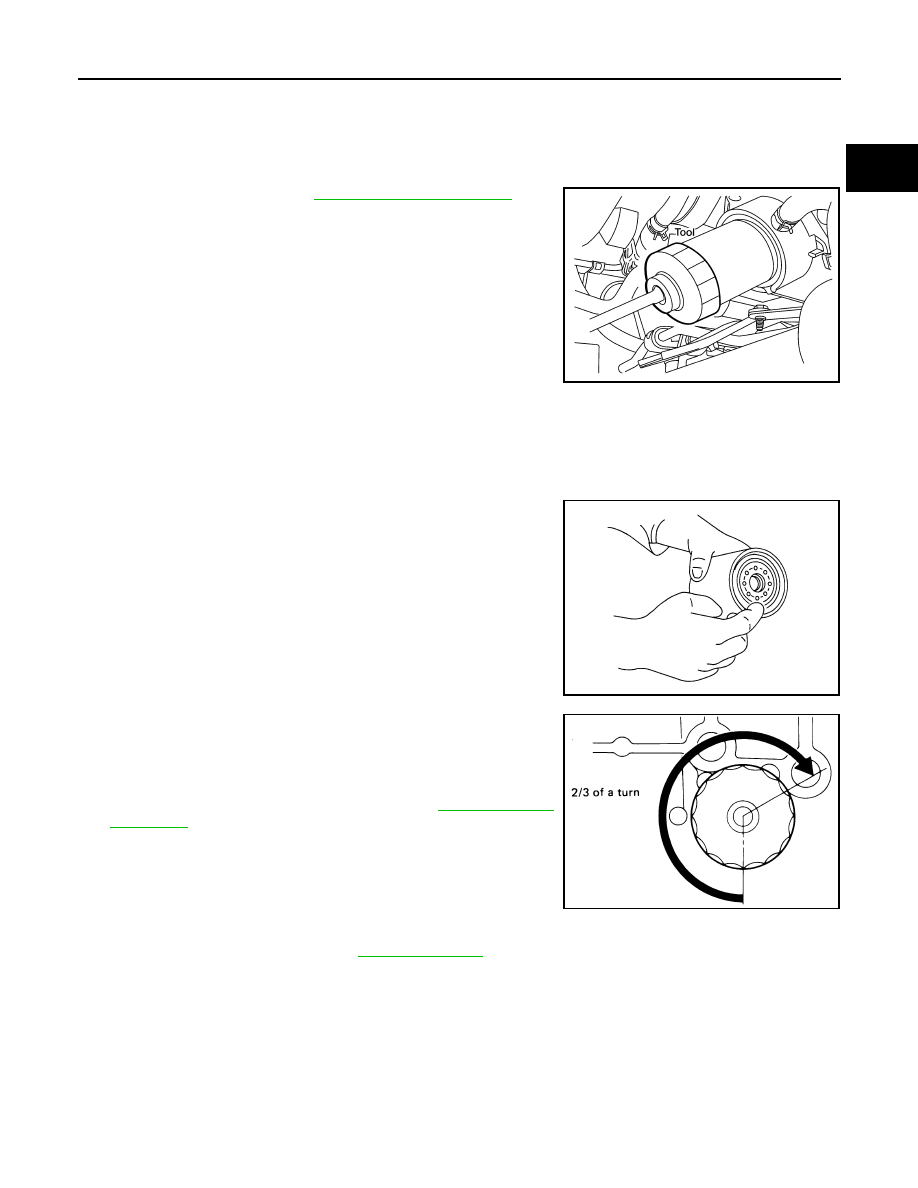

2. Remove the oil filter using Tool.

WARNING:

• Be careful not to get burned when the engine and engine

oil are hot.

CAUTION:

• The oil filter is provided with a relief valve.

• Use Genuine NISSAN oil filter or equivalent.

• When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the engine and the vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply engine oil to the oil seal circumference of the new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Refill the engine with new engine oil. Refer to

5. Inspect the engine for oil leakage. Follow the "INSPECTION

AFTER INSTALLATION" procedure.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to

.

2. Start the engine and check for engine oil leakage.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.

Tool number

: KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B