Infiniti QX56 (JA60). Manual - part 474

EM-50

< ON-VEHICLE REPAIR >

TIMING CHAIN

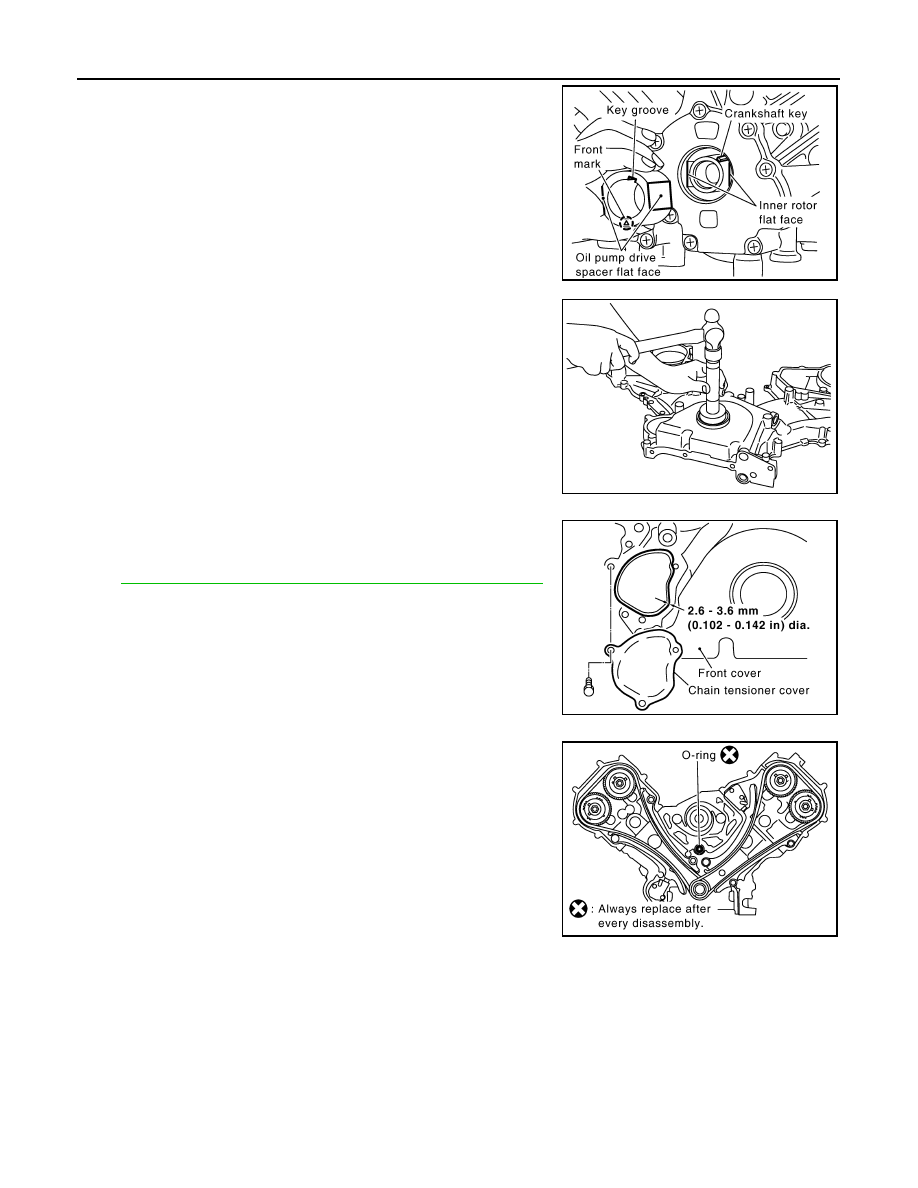

7. Install the oil pump drive spacer as follows:

• Install so that the front mark on the front edge of the oil pump

drive spacer faces the front of the engine.

• Insert the oil pump drive spacer according to the directions of

the crankshaft key and the two flat surfaces of the oil pump

inner rotor.

• If the positional relationship does not allow the insertion, rotate

the oil pump inner rotor to allow the oil pump drive spacer to

be inserted.

8. Install the front oil seal using suitable tool.

CAUTION:

Do not scratch or make burrs on the circumference of the

oil seal.

9. Install the chain tensioner cover.

• Apply liquid gasket as shown.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

10. Install the front cover as follows:

a. Install a new O-ring on the cylinder block.

KBIA2490E

PBIC0059E

KBIA2547E

KBIA2516E