Infiniti QX56 (JA60). Manual - part 433

EC-384

< COMPONENT DIAGNOSIS >

[VK56DE]

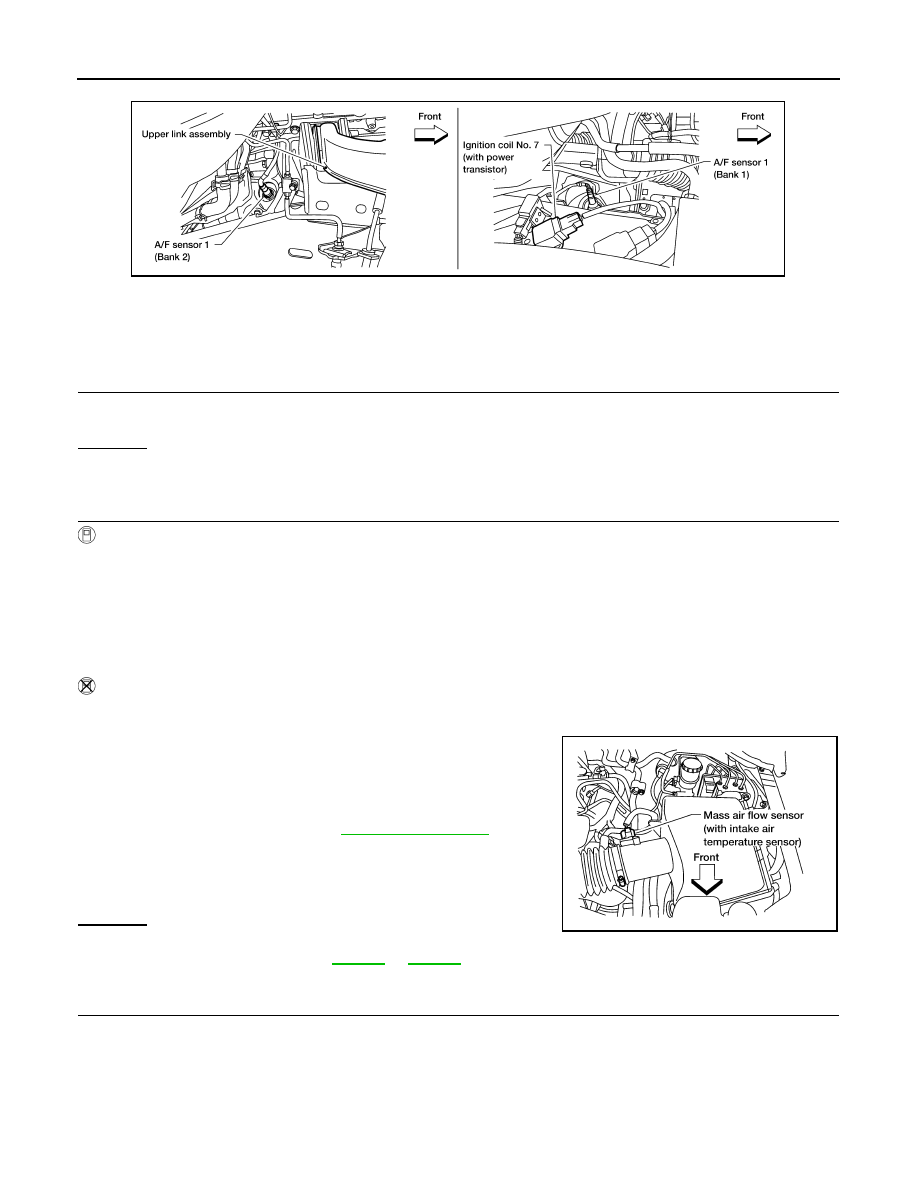

P2A00, P2A03 A/F SENSOR 1

1. Loosen and retighten the A/F sensor 1.

>> GO TO 3.

3.

CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace.

4.

CLEAR THE SELF-LEARNING DATA

With CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Select “SELF-LEARNING CONT” in “WORK SUPPORT” mode with CONSULT-III.

3. Clear the self-learning control coefficient by touching “CLEAR”.

4. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171, P0172, P0174 or P0175 detected?

Is it difficult to start engine?

Without CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF.

3. Disconnect mass air flow sensor harness connector.

4. Restart engine and let it idle for at least 5 seconds.

5. Stop engine and reconnect mass air flow sensor harness con-

nector.

6. Make sure DTC P0102 is displayed.

7. Erase the DTC memory. Refer to

8. Make sure DTC P0000 is displayed.

9. Run engine for at least 10 minutes at idle speed.

Is the 1st trip DTC P0171, P0172, P0174 or P0175 detected?

Is it difficult to start engine?

Yes or No

Yes

>> Perform trouble diagnosis for DTC P0171, P0174 or

P0172, P0175. Refer to

No

>> GO TO 5.

5.

CHECK HARNESS CONNECTOR

1. Turn ignition switch OFF.

Tightening torque: 50 N-m (5.1 kg-m, 37 ft-lb)

BBIA0375E

BBIA0368E