Infiniti QX56 (JA60). Manual - part 412

EC-300

< COMPONENT DIAGNOSIS >

[VK56DE]

P1211 TCS CONTROL UNIT

P1211 TCS CONTROL UNIT

Description

INFOID:0000000005149342

The malfunction information related to TCS is transferred through the CAN communication line from “ABS

actuator and electric unit (control unit)” to ECM.

Be sure to erase the malfunction information such as DTC not only for “ABS actuator and electric unit

(control unit)” but also for ECM after TCS related repair.

On Board Diagnosis Logic

INFOID:0000000005149343

Freeze frame data is not stored in the ECM for this self-diagnosis.

The MIL will not light up for this self-diagnosis.

DTC Confirmation Procedure

INFOID:0000000005149344

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5 V at idle.

1. Start engine and let it idle for at least 60 seconds.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000005149345

Go to

BRC-23, "CONSULT-III Function (ABS)"

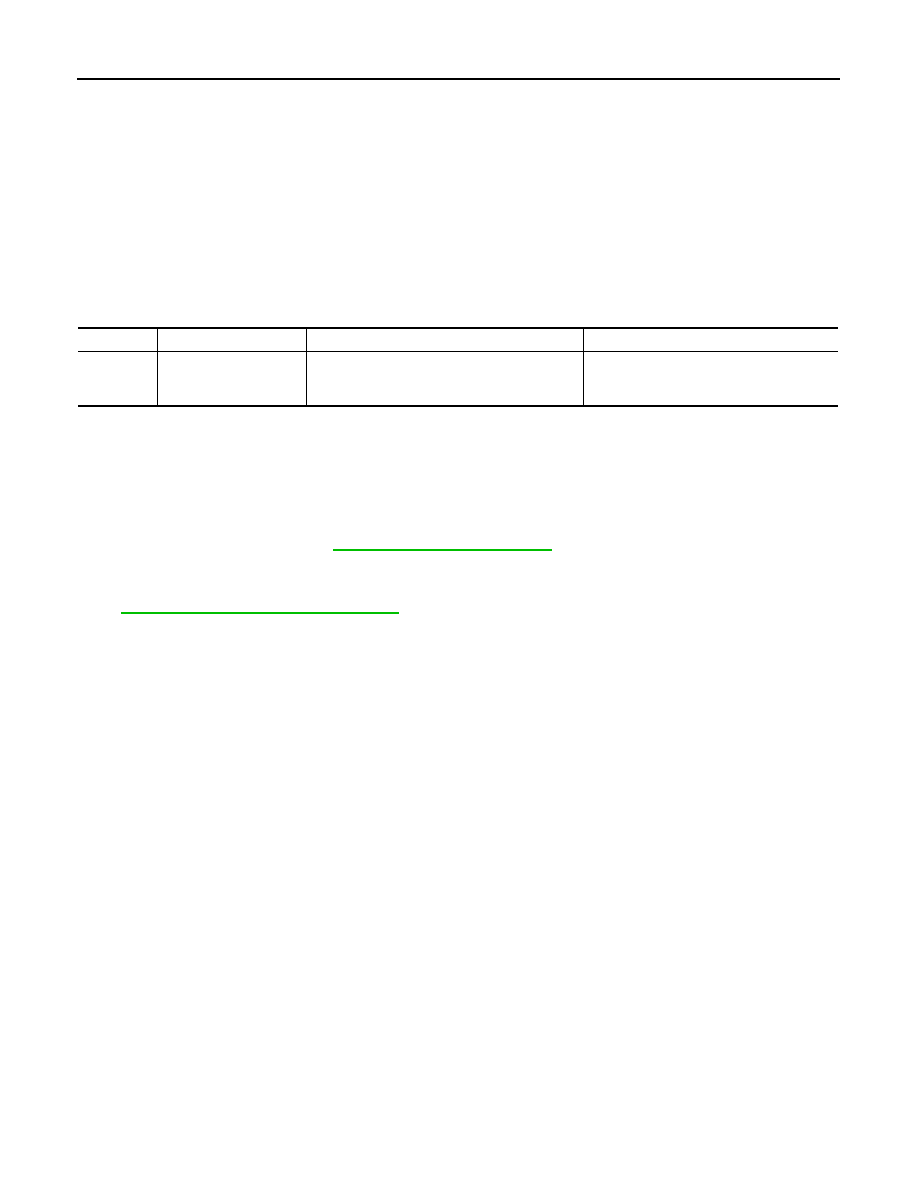

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P1211

1211

TCS control unit

ECM receives a malfunction information from

“ABS actuator electric unit (control unit)”

• ABS actuator and electric unit (control

unit)

• TCS related parts