Infiniti QX56 (JA60). Manual - part 324

FRONT FINAL DRIVE

DLN-219

< DISASSEMBLY AND ASSEMBLY >

[FRONT FINAL DRIVE: M205]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

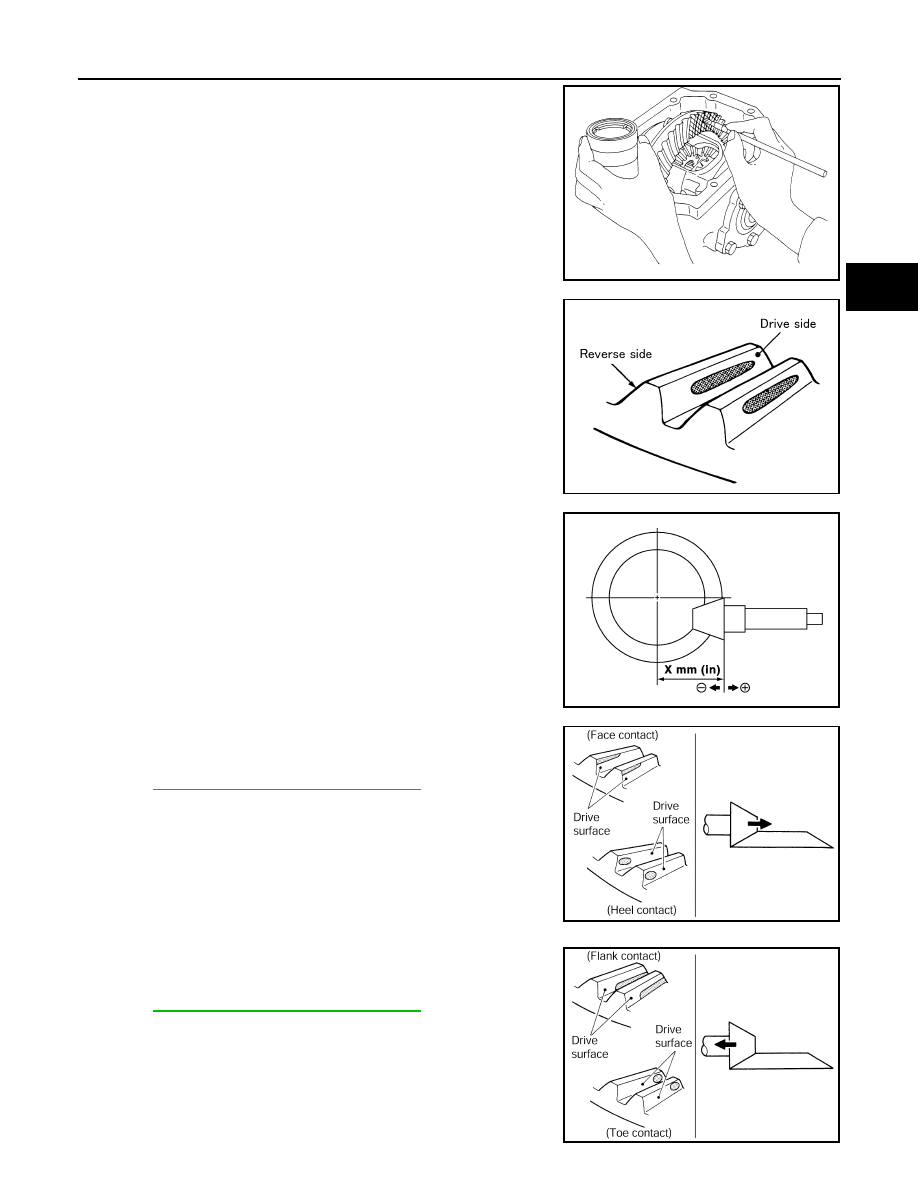

1. Apply red lead to the drive gear.

NOTE:

Apply red lead to both faces of three to four gears, at four loca-

tions evenly spaced on the drive gear.

2. Rotate the drive gear back and forth several times. Then check

for correct drive pinion to drive gear tooth contact as shown.

CAUTION:

Check tooth contact on drive side and reverse side.

3. If the tooth contact is improperly adjusted, follow the procedure

below to adjust the drive pinion height (dimension X).

• If the tooth contact is near the face (face contact), or near the heel

(heel contact), use a thicker drive pinion height adjusting washer to

move drive pinion closer to the drive gear.

DLN-234, "Inspection and Adjustment"

• If the tooth contact is near the flank (flank contact), or near the toe

(toe contact), use a thinner drive pinion height adjusting washer to

move the drive pinion farther from the drive gear.

DLN-234, "Inspection and Adjustment"

SPD357

SDIA0570E

SDIA0517E

PDIA0440E

PDIA0441E