Infiniti QX56 (JA60). Manual - part 13

B2126 DETENT SW

ADP-43

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

M

A

B

ADP

N

O

P

NO

>> GO TO 3

3.

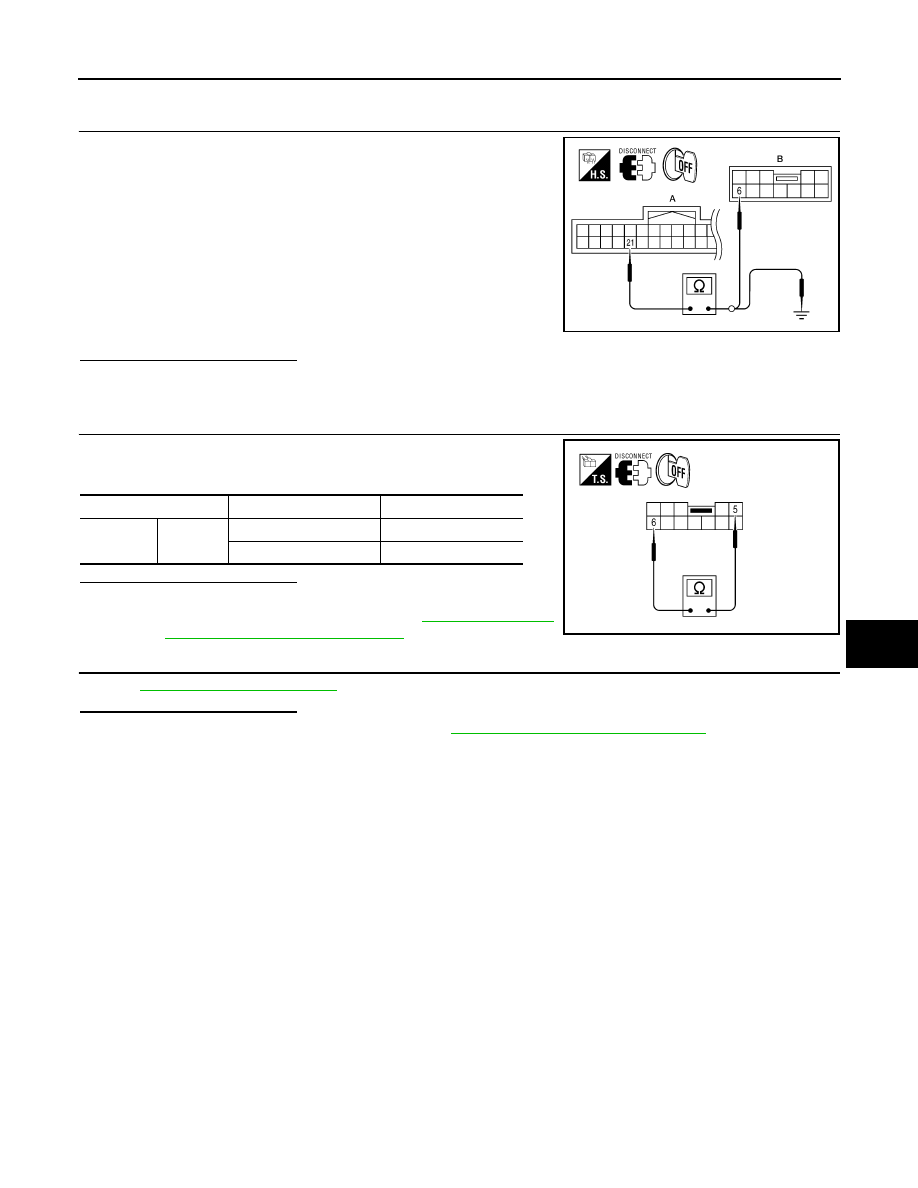

CHECK A/T SHIFT SELECTOR (PARK POSITION SWITCH) HARNESS

1. Turn ignition switch OFF.

2. Disconnect A/T shift selector and driver seat control unit.

3. Check continuity between driver seat control unit connector

B202 (A) terminal 21 and A/T shift selector connector M203 (B)

terminal 6.

4. Check continuity between driver seat control unit connector

B202 (A) terminal 21 and ground.

Is the inspection result normal?

YES

>> GO TO 4

NO

>> Repair or replace harness.

4.

CHECK PARK POSITION SWITCH

Check continuity between A/T shift selector (park position switch)

terminals as follows.

Is the inspection result normal?

YES

>> GO TO 5

NO

>> Replace A/T shift selector. Refer to

Selector Removal and Installation"

.

5.

CHECK INTERMITTENT INCIDENT

GI-38, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace driver seat control unit. Refer to

ADP-174, "Removal and Installation"

NO

>> Repair or replace the malfunctioning part.

6 - 21

: Continuity should exist.

21 - Ground

: Continuity should not exist.

ALJIA0194ZZ

Terminals

Condition

Continuity

5

6

P position

Yes

Other than P position

No

ALJIA0486ZZ