Infiniti QX56 (Z62). Manual - part 729

FAX-18

< REMOVAL AND INSTALLATION >

[4WD]

FRONT WHEEL HUB AND KNUCKLE

REMOVAL AND INSTALLATION

FRONT WHEEL HUB AND KNUCKLE

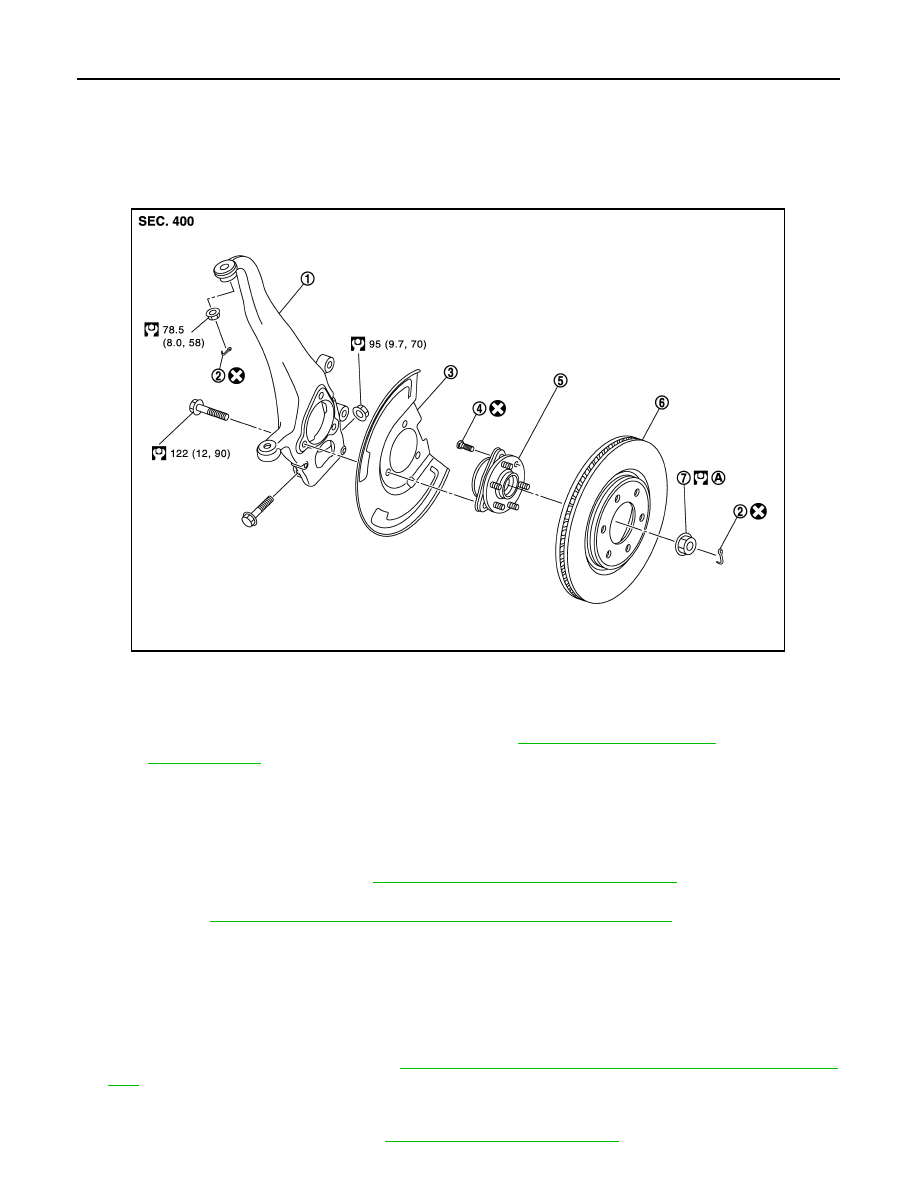

Exploded View

INFOID:0000000006225396

Removal and Installation

INFOID:0000000006225397

REMOVAL

1.

Remove tires.

2.

Remove brake hose bracket. Refer to

BR-23, "FRONT : Removal and Installation"

3.

Remove caliper assembly mounting bolts. Hang caliper assembly in a place where it will not interfere with

work. Refer to

BR-37, "BRAKE CALIPER ASSEMBLY : Removal and Installation"

CAUTION:

Never depress brake pedal while brake caliper is removed.

4.

Remove disc rotor.

CAUTION:

• Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

• Never drop disc rotor.

5.

Remove wheel sensor harness. Refer to

BRC-134, "FRONT WHEEL SENSOR : Removal and Installa-

CAUTION:

Never pull on wheel sensor harness.

6.

Remove steering outer socket. Refer to

ST-42, "Removal and Installation"

1.

Steering knuckle

2.

Cotter pin

3.

Splash guard

4.

Hub bolt

5.

Wheel hub and bearing assembly

6.

Disc rotor

7.

Wheel hub lock nut

A.

Tightening must be done following the installation procedure. Refer to

FAX-18, "Removal and Installation"

Refer to

for symbols in the figure.

JPDIF0298GB