Infiniti QX56 (Z62). Manual - part 726

FAX-6

< SYMPTOM DIAGNOSIS >

[2WD]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

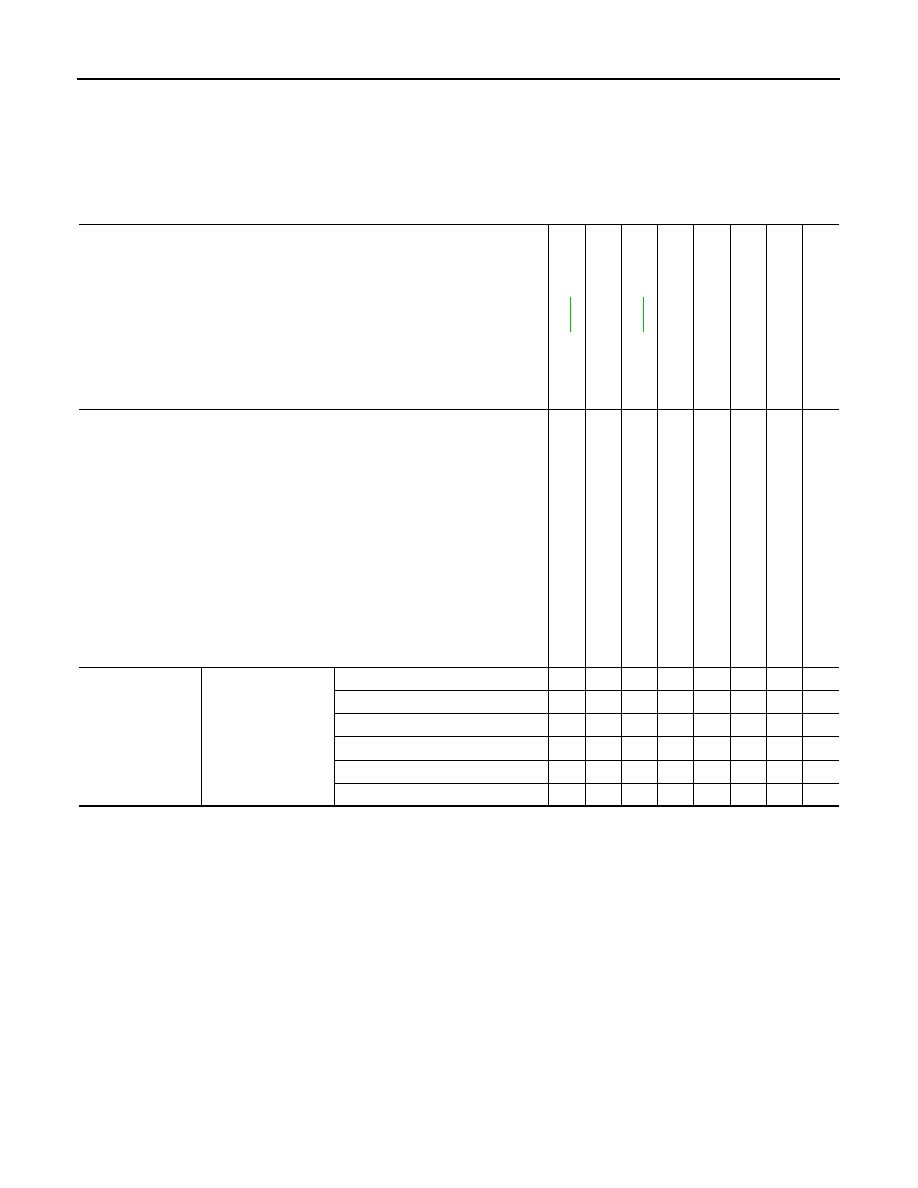

NVH Troubleshooting Chart

INFOID:0000000006225415

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×

: Applicable

Reference

—

NVH in

F

AX an

d F

S

U

s

e

c

ti

o

ns

NVH in WT section

NVH in WT section

NVH in B

R

section

NVH in S

T

section

Possible cause and SUSPECTED PARTS

Im

p

rop

er i

n

s

ta

lla

tio

n

,

lo

os

en

es

s

P

a

rt

s interference

W

he

el be

arin

g da

ma

ge

F

R

ONT

AXLE AND FRONT S

U

SPENSION

TI

RE

ROAD W

H

EEL

BR

AK

E

S

T

EERING

Symptom

FRONT AXLE

Noise

×

×

×

×

×

×

×

×

Shake

×

×

×

×

×

×

×

×

Vibration

×

×

×

×

×

×

Shimmy

×

×

×

×

×

×

×

Judder

×

×

×

×

×

×

Poor quality ride or handling

×

×

×

×

×