Infiniti QX56 (Z62). Manual - part 602

EC-386

< DTC/CIRCUIT DIAGNOSIS >

[VK56VD]

P1087, P1088 VVEL SYSTEM

P1087, P1088 VVEL SYSTEM

DTC Logic

INFOID:0000000006217892

DTC DETECTION LOGIC

NOTE:

If DTC P1087 or P1088 is displayed with DTC P1090 or P1093.

Perform the trouble diagnosis for DTC P1090 or P1093. Refer to

Diagnosis Procedure

INFOID:0000000006217893

If DTC P1087 or P1088 is displayed with DTC P1090 or P1093.

Perform the trouble diagnosis for DTC P1090 or P1093. Refer to

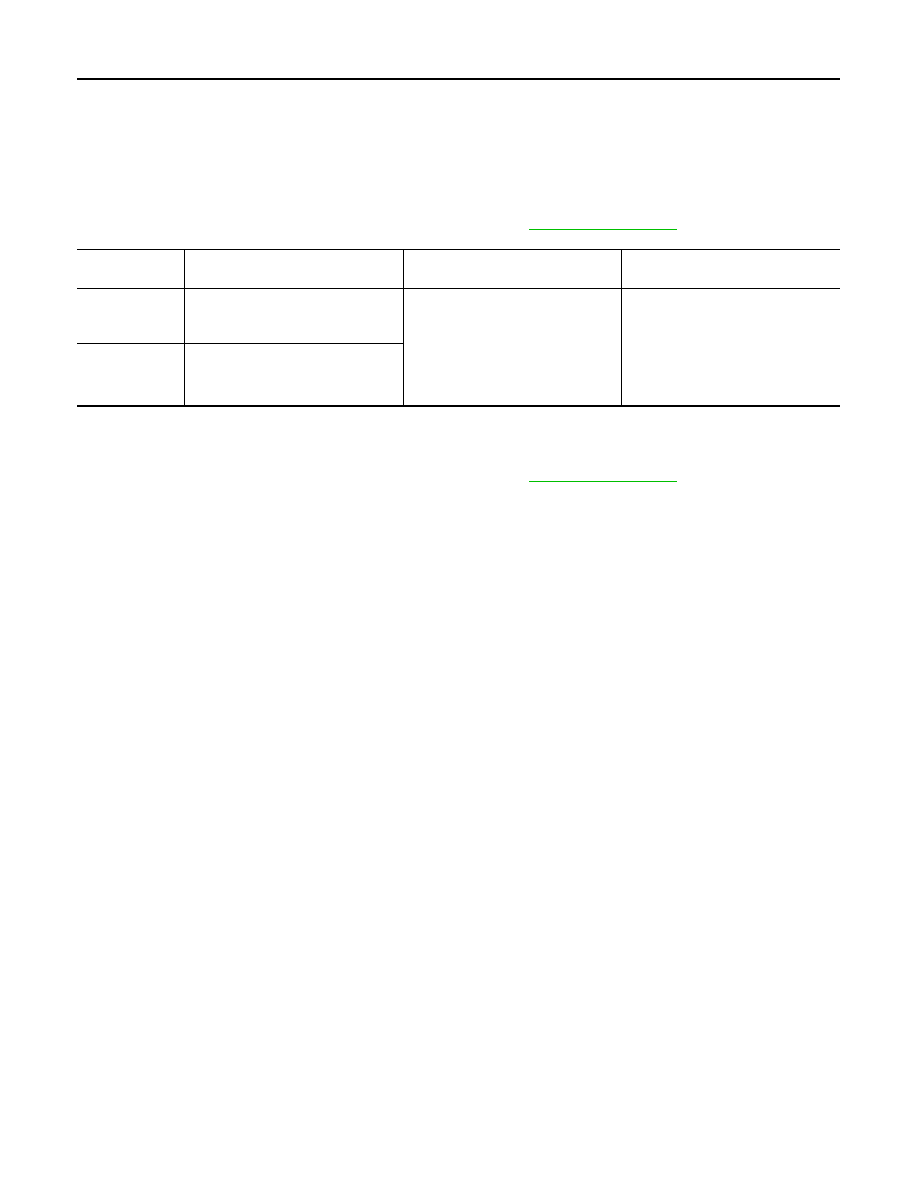

DTC No.

Trouble diagnosis name

(Trouble diagnosis content)

DTC detecting condition

Possible cause

P1087

VVEL SYSTEM-B1

[VVEL small event angle malfunction

(bank 1)]

The event angle of VVEL control

shaft is always small.

• Harness or connectors

(VVEL actuator motor assembly

circuit is open or shorted.)

• VVEL actuator motor assembly

• VVEL actuator housing assembly

• VVEL ladder assembly

• VVEL control module

P1088

VVEL SYSTEM-B2

[VVEL small event angle malfunction

(bank 2)]