Infiniti QX56 (Z62). Manual - part 582

EC-306

< DTC/CIRCUIT DIAGNOSIS >

[VK56VD]

P0340, P0345 CMP SENSOR

YES

>> GO TO 11

NO

>> Replace malfunctioning camshaft position sensor. Refer to

.

11.

CHECK CAMSHAFT (INT)

Check the following.

• Accumulation of debris to the signal plate of camshaft front end

• Chipping signal plate of camshaft front end

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Remove debris and clean the signal plate of camshaft

front end or replace camshaft.

12.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection (Camshaft Position Sensor)

INFOID:0000000006217850

1.

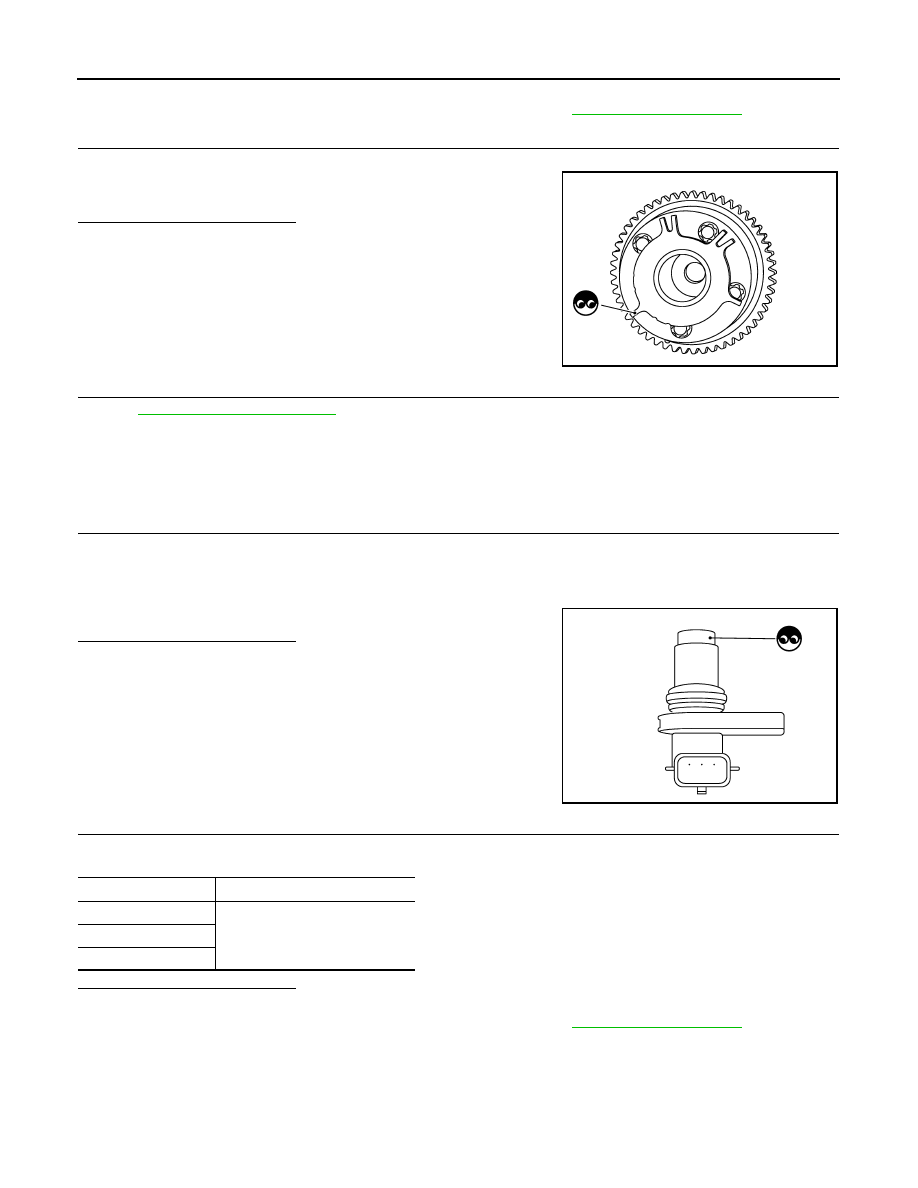

CHECK CAMSHAFT POSITION SENSOR-I

1.

Turn ignition switch OFF.

2.

Loosen the fixing bolt of the sensor.

3.

Disconnect camshaft position sensor harness connector.

4.

Remove the sensor.

5.

Visually check the sensor for chipping.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace malfunctioning camshaft position sensor.

2.

CHECK CAMSHAFT POSITION SENSOR-II

Check resistance camshaft position sensor terminals as per the following.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace malfunctioning camshaft position sensor. Refer to

.

JMBIA0962ZZ

JMBIA0065ZZ

Terminals (Polarity)

Resistance

1 (+) - 2 (-)

Except 0 or

∞

Ω

[at 25

°

C (77

°

F)]

1 (+) - 3 (-)

2 (+) - 3 (-)