Infiniti QX56 (Z62). Manual - part 577

EC-286

< DTC/CIRCUIT DIAGNOSIS >

[VK56VD]

P0197, P0198 EOT SENSOR

YES

>> GO TO 3.

NO

>> Repair open circuit, short to ground or short to power in harness or connectors.

3.

CHECK ENGINE OIL TEMPERATURE SENSOR

EC-286, "Component Inspection (Engine Oil Temperature Sensor)"

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Replace engine oil temperature sensor. Refer to

4.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection (Engine Oil Temperature Sensor)

INFOID:0000000006217834

1.

CHECK ENGINE OIL TEMPERATURE SENSOR

1.

Turn ignition switch OFF.

2.

Disconnect engine oil temperature sensor harness connector.

3.

Remove engine oil temperature sensor.

4.

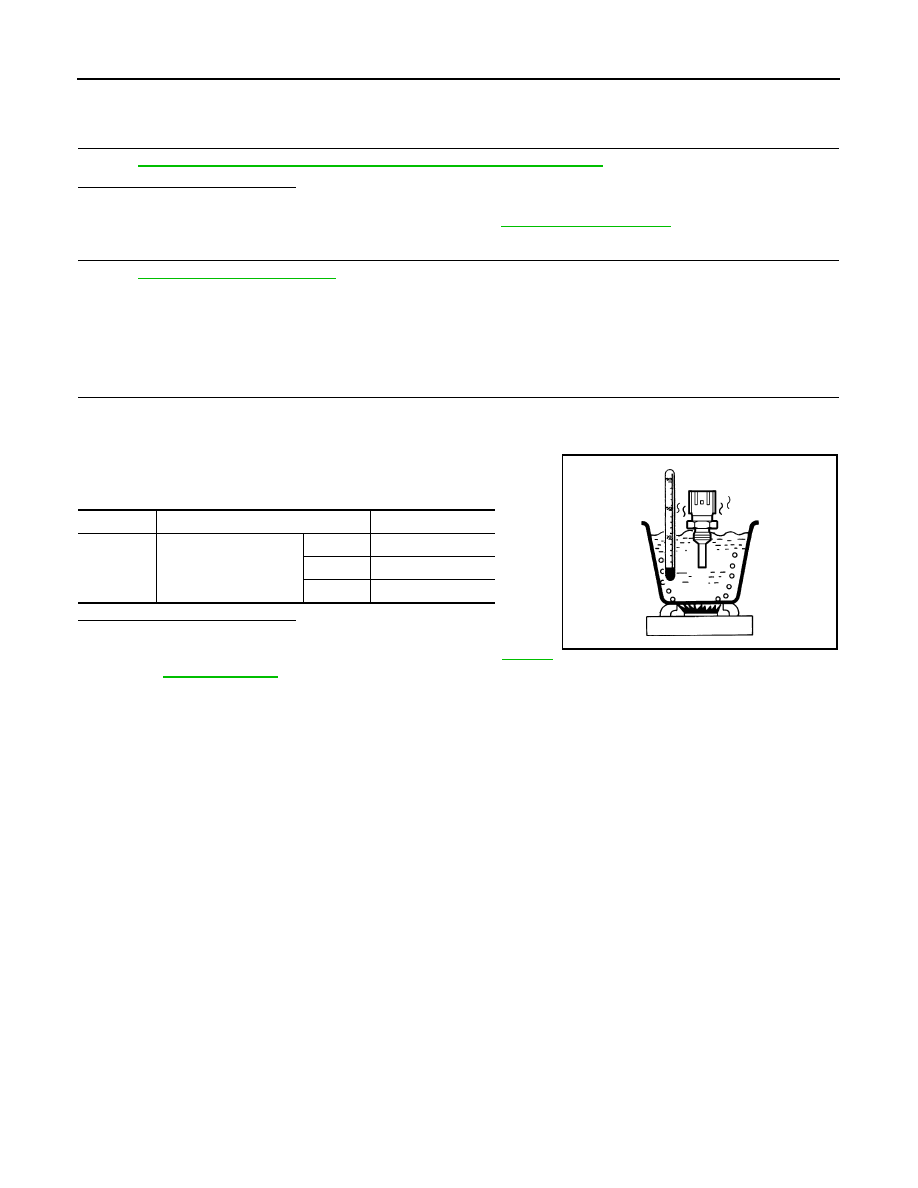

Check resistance between engine oil temperature sensor termi-

nals by heating with hot water as shown in the figure.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace engine oil temperature sensor. Refer to

.

Terminals

Condition

Resistance (k

Ω

)

1 and 2

Temperature [

°

C (

°

F)]

20 (68)

2.35 - 2.73

50 (122)

0.68 - 1.00

90 (194)

0.236 - 0.260

JMBIA0080ZZ