Infiniti QX56 (Z62). Manual - part 504

DLN-216

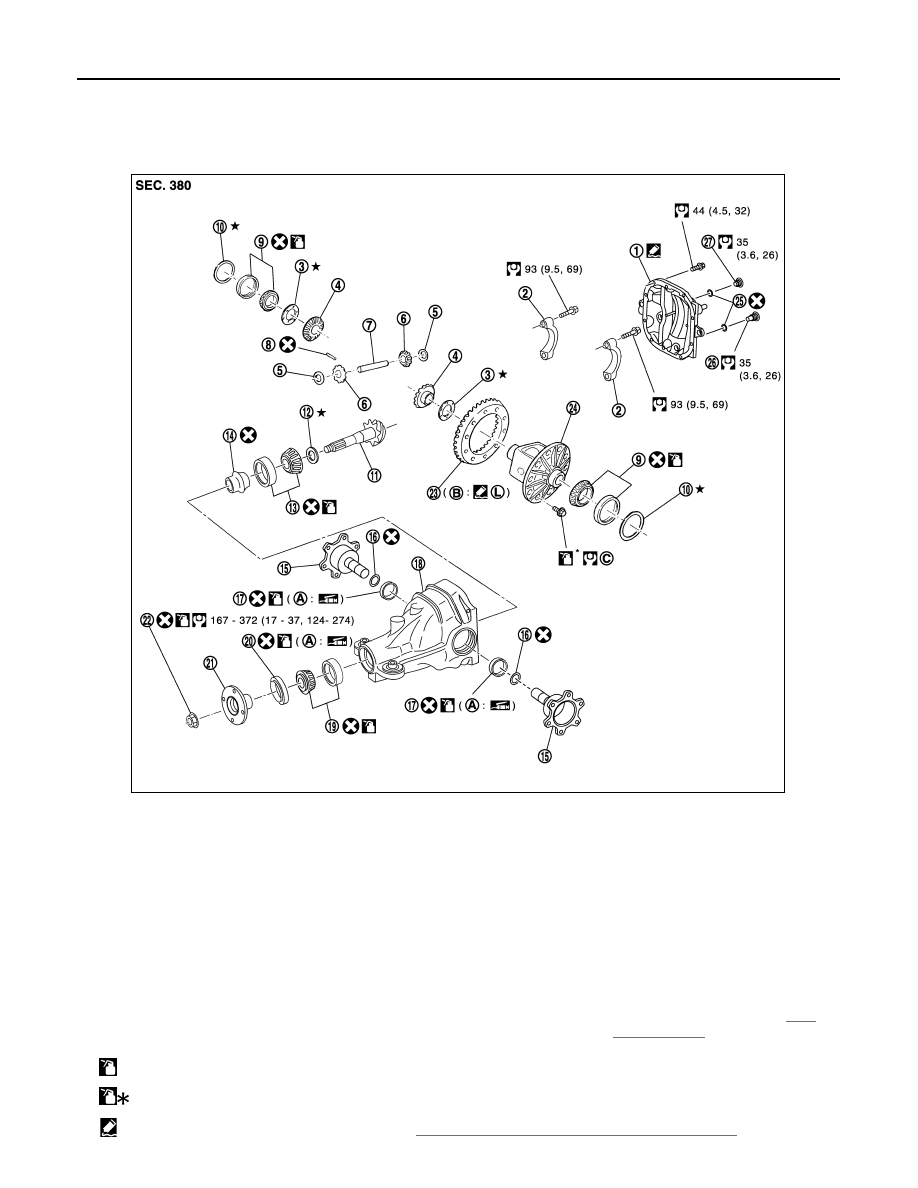

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R230]

DRIVE PINION

DRIVE PINION

Exploded View

INFOID:0000000006222425

1.

Rear cover

2.

Bearing cap

3.

Side gear thrust washer

4.

Side gear

5.

Pinion mate thrust washer

6.

Pinion mate gear

7.

Pinion mate shaft

8.

Lock pin

9.

Side bearing

10. Side bearing adjusting washer

11.

Drive pinion

12. Pinion height adjusting washer

13. Pinion rear bearing

14. Collapsible spacer

15. Side flange

16. Circlip

17. Side oil seal

18. Gear carrier

19. Pinion front bearing

20. Front oil seal

21. Companion flange

22. Drive pinion lock nut

23. Drive gear

24. Differential case

25. Gasket

26. Drain plug

27. Filler plug

A.

Oil seal lip

B.

Screw hole

C.

Comply with the assembly proce-

dure when tightening. Refer to

: Apply gear oil.

: Apply anti-corrosion oil.

: Apply Genuine Silicone RTV or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

JPDID0397GB