Content .. 1296 1297 1298 1299 ..

Infiniti QX56 (Z62). Manual - part 1298

A/T POSITION

TM-101

< BASIC INSPECTION >

[7AT: RE7R01B]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

A/T POSITION

Inspection

INFOID:0000000006226794

1.

Place selector lever in “P” position, and turn ignition switch ON (engine stop).

2.

Check that selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

check that selector lever can be shifted from “P” position only when brake pedal is depressed.

3.

Shift the selector lever and check for excessive effort, sticking, noise or rattle.

4.

Confirm that the selector lever stops at each position by feeling the engagement when it is moved through

all the positions. Check whether or not the actual position the selector lever matches the position shown

by the shift position indicator and the A/T body.

5.

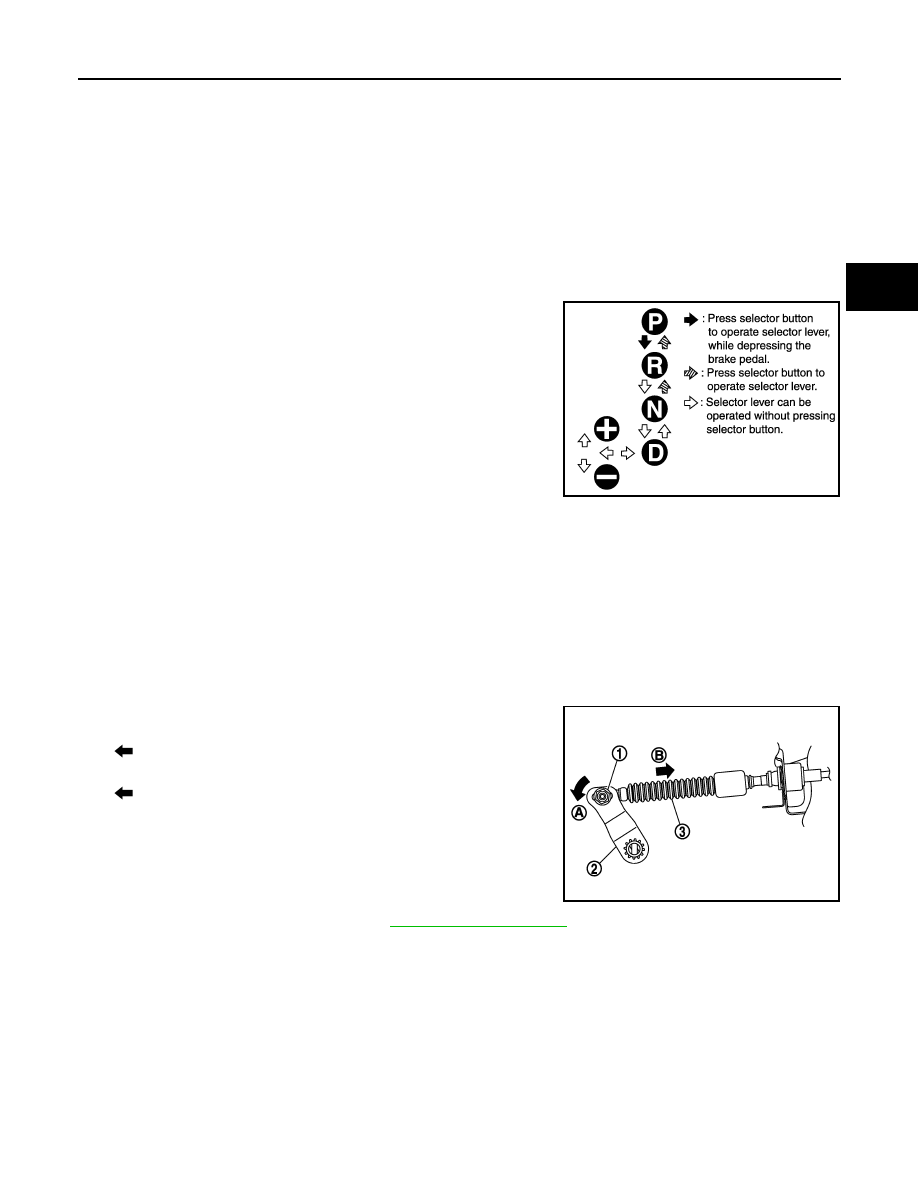

The method of operating the lever to individual positions cor-

rectly is shown in the figure.

6.

When selector button is pressed in “P”, “R”, or “N” position with-

out applying forward/backward force to selector lever, check but-

ton operation for sticking.

7.

Confirm that the back-up lamps illuminate only when lever is

placed in the “R” position. Confirm that the back-up lamps do not

illuminate when selector lever is pushed against “R” position in

the “P” or “N” position.

8.

Confirm that the engine can only be started with the selector

lever in the “P” and “N” positions. (With selector lever in the “P”

position, engine can be started even when selector lever is

moved forward and backward.)

9.

Make sure that A/T is locked completely in “P” position.

10. When selector lever is set to manual shift gate, make sure that manual mode is displayed on combination

meter.

In addition, a set shift position must be changed when the selector lever is shifted to the “+” or “

−

” side in

the manual mode. (Only while driving.)

Adjustment

INFOID:0000000006379166

1.

Shift selector lever in “P” position.

2.

Loosen nut (1).

3.

Turn the manual lever (2) all the way in the “P” range direction

[

(A)].

4.

Hold and push the control cable (3) in the vehicle front direction

[

(B)], and tighten the nut by hand with cable set in free condi-

tion.

CAUTION:

Be careful not put any load to manual lever.

NOTE:

Press control cable with a force of 9.8 N (approximately 1 kg, 2.2

lb).

5.

Tighten nut to specified torque. Refer to

.

JSDIA0790GB

JSDIA1587ZZ