Content .. 1253 1254 1255 1256 ..

Infiniti QX56 (Z62). Manual - part 1255

ST-30

< PERIODIC MAINTENANCE >

POWER STEERING FLUID

PERIODIC MAINTENANCE

POWER STEERING FLUID

Inspection

INFOID:0000000006225597

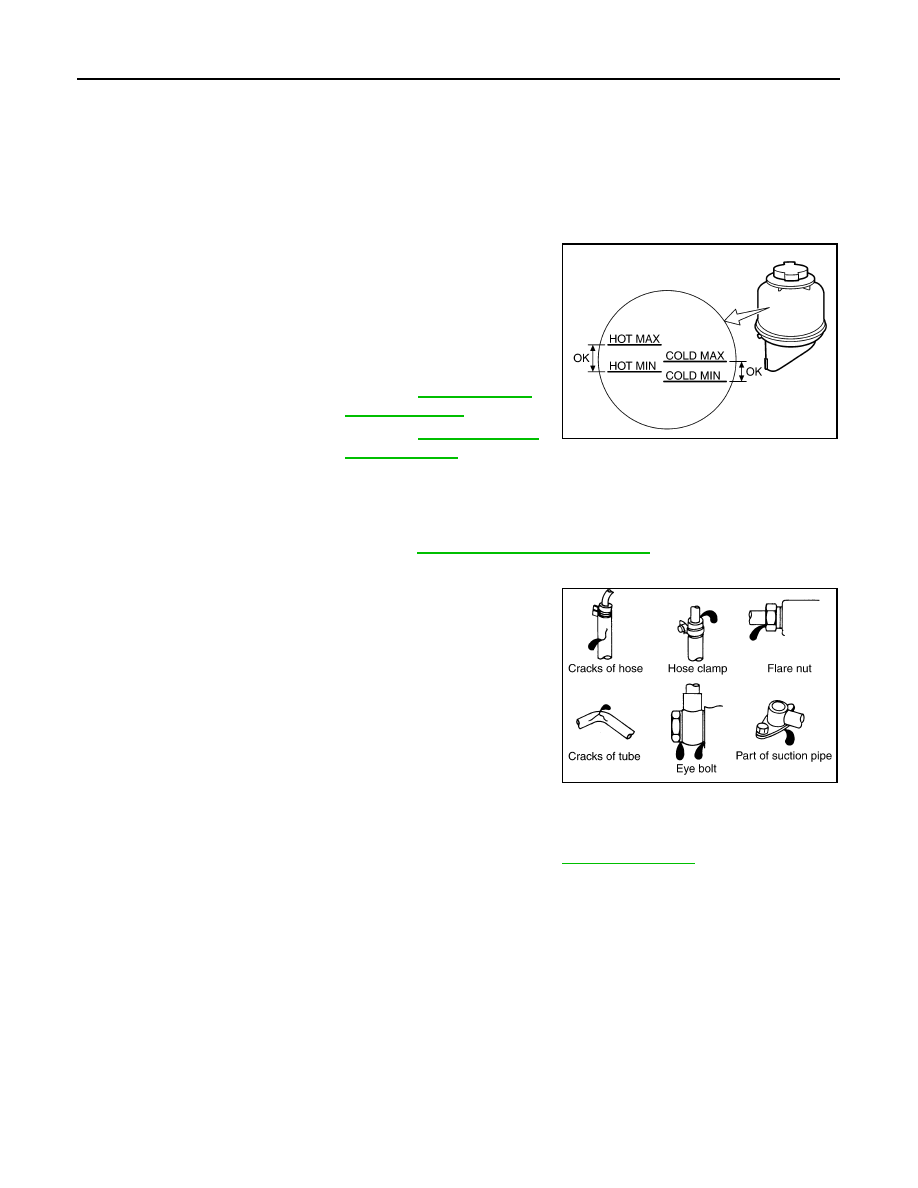

FLUID LEVEL

1.

Check fluid level with engine stopped.

2.

Ensure that fluid level is between MIN and MAX.

3.

Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

• The fluid level should not exceed the MAX line. Excessive fluid causes fluid leakage from the

cap.

• Never reuse drained power steering fluid.

• Always use the specified fluid. Refer to

MA-10, "Fluids and Lubricants"

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1.

Run engine until the fluid temperature reaches 50 to 80

°

C (122

to 176

°

F) in reservoir tank, and keep engine speed idle.

2.

Turn steering wheel several times from full left stop to full right

stop.

3.

Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4.

If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5.

If fluid leakage from oil pump is noticed, check oil pump. Refer to

.

6.

Check steering gear boots for accumulation of fluid indicating from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

• Bubbles are created in reservoir tank.

• Clicking noise can be heard from oil pump.

• Excessive buzzing in the oil pump.

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1.

Turn steering wheel several times from full left stop to full right stop with engine off.

CAUTION:

Fill reservoir tank with a sufficient amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2.

Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

HOT

: Fluid temperature 50 – 80

°

C (122 – 176

°

F)

COLD

: Fluid temperature 0 – 30

°

C (32 – 86

°

F)

Recommended fluid

: Refer to

.

Fluid capacity

: Refer to

.

SGIA0232J

SGIA0506E