Content .. 1050 1051 1052 1053 ..

Infiniti QX56 (Z62). Manual - part 1052

REAR WHEEL HUB AND HOUSING

RAX-9

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

RAX

N

O

P

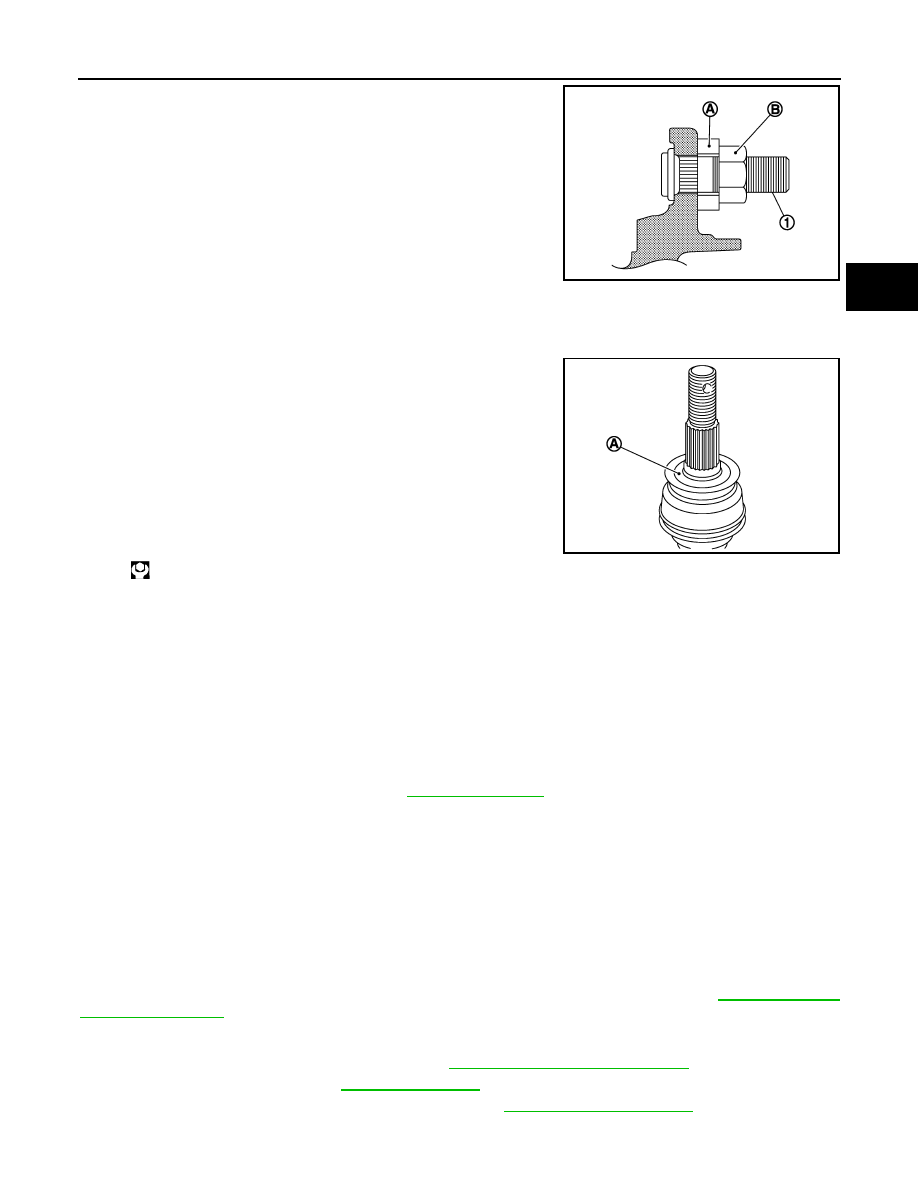

• Place a suitable washer (A) as shown in the figure to install the hub

bolts (1) by using the tightening force of the nut (B).

CAUTION:

• Check that there is no clearance between wheel hub and

bearing assembly, and hub bolt.

• Never reuse hub bolt.

• Clean the matching surface of wheel hub lock nut and wheel hub and bearing assembly.

CAUTION:

Never apply lubricating oil to these matching surface.

• Clean the matching surface of drive shaft and wheel hub and bear-

ing assembly. And then apply paste [service parts (440037S000)]

to surface (A) of joint sub-assembly of drive shaft.

CAUTION:

Apply paste to cover entire flat surface of joint sub-assembly

of drive shaft.

• Use the following torque range for tightening the wheel hub lock

nut.

CAUTION:

• Since the drive shaft is assembled by press-fitting, use the tightening torque range for the wheel

hub lock nut.

• Be sure to use torque wrench to tighten the wheel hub lock nut. Never use a power tool.

NOTE:

Wheel hub lock nut tightening torque does not over torque for avoiding axle noise, and does not less than

torque for avoiding looseness.

• Perform the final tightening of each of parts under unladen conditions, which were removed when removing

wheel hub and bearing assembly and axle housing.

• When installing the adjusting cap, check that there must be no play.

• Never reuse cotter pin, wheel hub lock nut, and bushing.

• Perform inspection after installation. Refer to

.

Inspection

INFOID:0000000006225467

INSPECTION AFTER REMOVAL

Wheel Hub and Bearing Assembly

Check the wheel hub and bearing assembly for wear, cracks, and damage. Replace if necessary.

Axle Housing

Check the axle housing for wear, cracks, and damage. Replace if necessary.

Ball Joint Inspection

Check for boot breakage, axial looseness, and torque of suspension arm ball joint. Refer to

.

INSPECTION AFTER INSTALLATION

1.

Adjust parking brake operation (stroke). Refer to

PB-3, "Inspection and Adjustment"

2.

Check wheel alignment. Refer to

3.

Adjust neutral position of steering angle sensor. Refer to

.

JPDIF0300ZZ

Amount paste

1.0 – 3.0 g (0.04 – 0.10 oz)

: 218 – 223 N·m (22.3 – 22.7 kg-m, 161 – 164 ft-lb)

JPDIG0122ZZ