Infiniti Q45. Manual - part 714

ENGINE OIL

LU-7

C

D

E

F

G

H

I

J

K

L

M

A

LU

5.

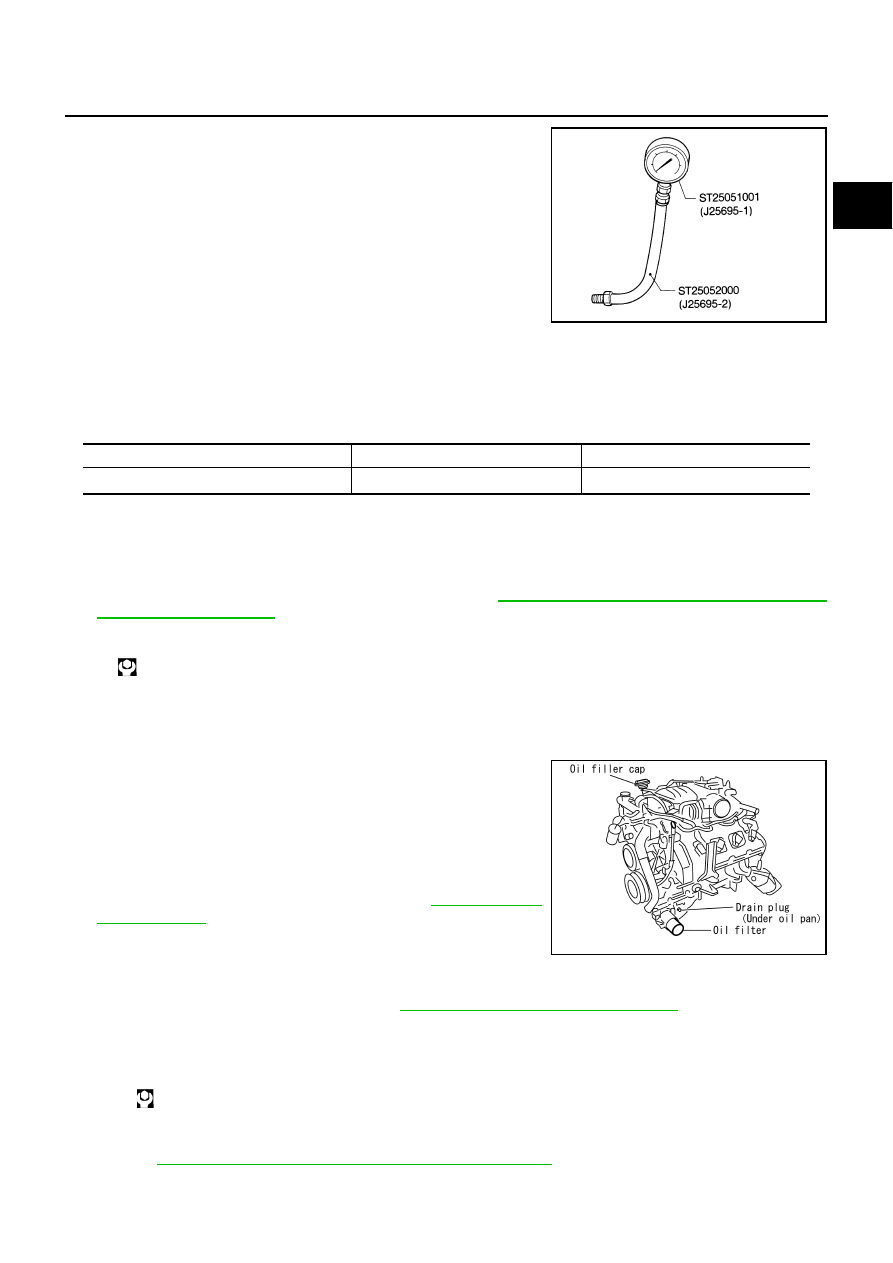

Install oil pressure gauge and hose [SST].

6.

After warming up engine to normal operating temperature, make sure that engine oil pressure corre-

sponding to the engine speed is produced.

NOTE:

When engine oil temperature is low, the engine oil pressure becomes high.

Engine oil pressure [Engine oil temperature at 80

°

C (176

°

F)]

If difference is extreme, check the oil passage and oil pump for engine oil leaks.

7.

After checking, install oil pressure switch as follows.

a.

Remove old liquid gasket adhering to oil pressure switch and engine.

b.

Apply thread sealant and tighten oil pressure switch to the specification.

Use Genuine Thread Sealant or equivalent. Refer to

GI-45, "RECOMMENDED CHEMICAL PROD-

c.

After warming up the engine, make sure there is no leaks of engine oil with running the engine.

Changing Engine Oil

NBS001PC

WARNING:

●

Be careful not to burn yourself, as engine oil is hot.

●

Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used engine oil. If skin contact is made, wash thoroughly

with soap or hand cleaner as soon as possible.

1.

Open oil filter installation/removal cover on engine undercover.

2.

Warm up engine, put vehicle horizontally and check for engine

oil leakage from engine components. Refer to

3.

Stop engine and wait for 15 minutes.

4.

Loosen oil filler cap, then remove drain plug.

5.

Drain engine oil.

6.

Install drain plug with new washer. Refer to

EM-26, "OIL PAN AND OIL STRAINER"

CAUTION:

●

Be sure to clean drain plug and install with new washer.

7.

Refill with new engine oil.

Engine oil specification and viscosity:

Refer to

MA-10, "RECOMMENDED FLUIDS AND LUBRICANTS"

SLC926

Engine speed (rpm)

Idle speed

2,000

Oil pressure kPa (kg/cm

2

, psi)

98 (1.0, 14)

294 (3.0, 43)

Oil pressure switch:

: 14.8 N·m (1.5 kg-m, 11 ft-lb)

Oil pan drain plug:

: 34.3 N·m (3.5 kg-m, 25 ft-lb)

PBIC0001E