Infiniti Q45. Manual - part 583

FUEL TANK

FL-9

C

D

E

F

G

H

I

J

K

L

M

A

FL

6.

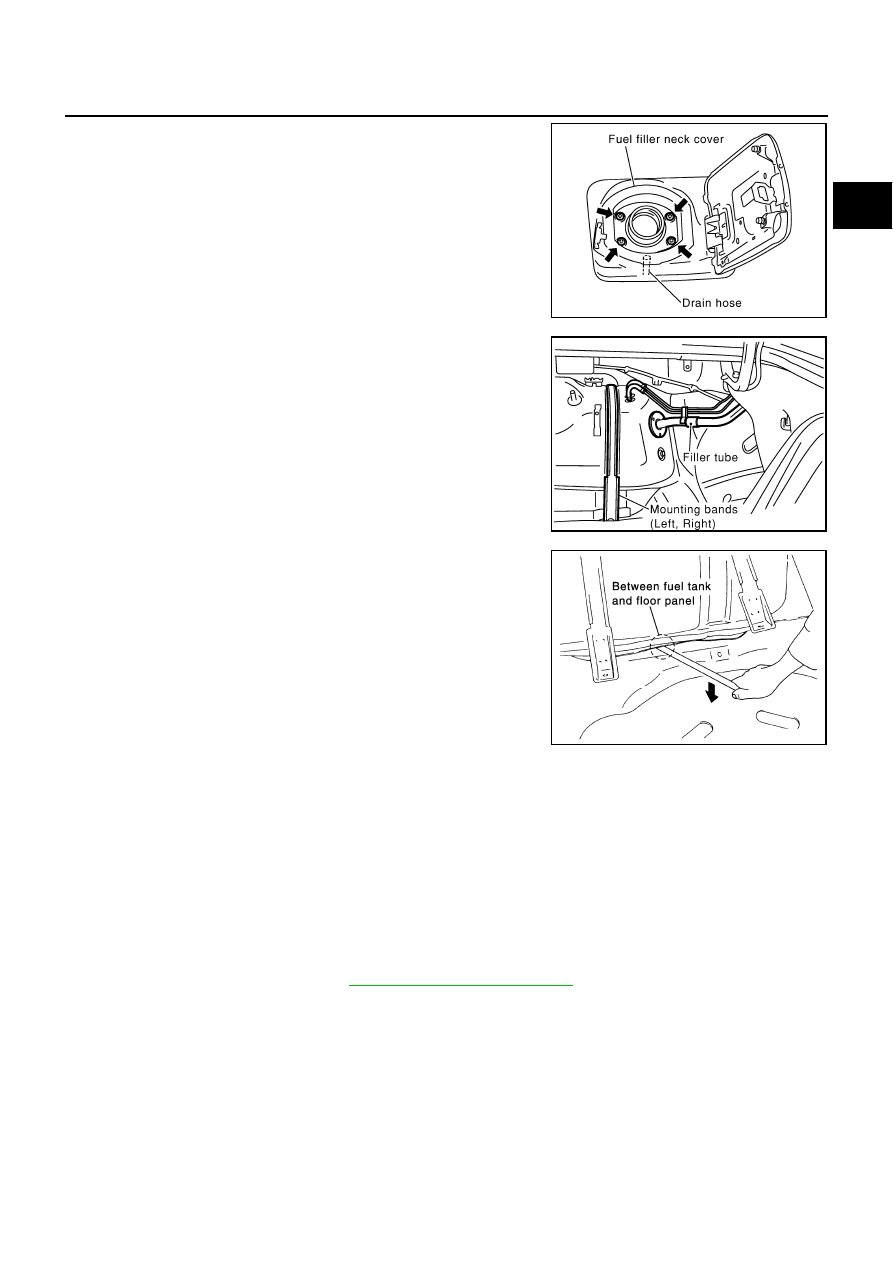

Remove fuel filler neck cover.

7.

Remove filer tube.

8.

Remove fuel tank mounting band mounting bolts.

9.

If the bottom of fuel tank hard contacts to remove from trunk

floor panel, insert a wood block or something similar to separate

them.

CAUTION:

Use a shop cloth or others like that to avoid deformation or

damage to fuel tank and the floor panel.

10. Pull fuel tank backwards to remove.

INSTALLATION

Note the following, and install in the reverse order of removal.

●

Push mounting band pin to the vehicle side securely.

●

Referring to the mating marks marked during removal, install fuel tubes and EVAP tubes and fix to the

clamps securely.

●

Before fixing fuel tank, temporarily install filler tube.

CAUTION:

Use genuine filler tube mounting bolts or equivalent. Make sure to tighten them to the specified

torque.

●

To connect quick connector, refer to

FL-3, "Removal and Installation"

.

INSPECTION AFTER INSTALLATION

After installing tubes, make sure there is no fuel leakage at connections in the following steps.

●

Apply fuel pressure to fuel lines with turning ignition switch “ON” (with engine stopped). Then check for

fuel leaks at connections.

●

Start engine and rev it up and check for fuel leaks at connections.

PBIC2131E

PBIC0169E

PBIC1196E