Infiniti Q45. Manual - part 458

DTC P0461 FUEL LEVEL SENSOR

EC-471

C

D

E

F

G

H

I

J

K

L

M

A

EC

7.

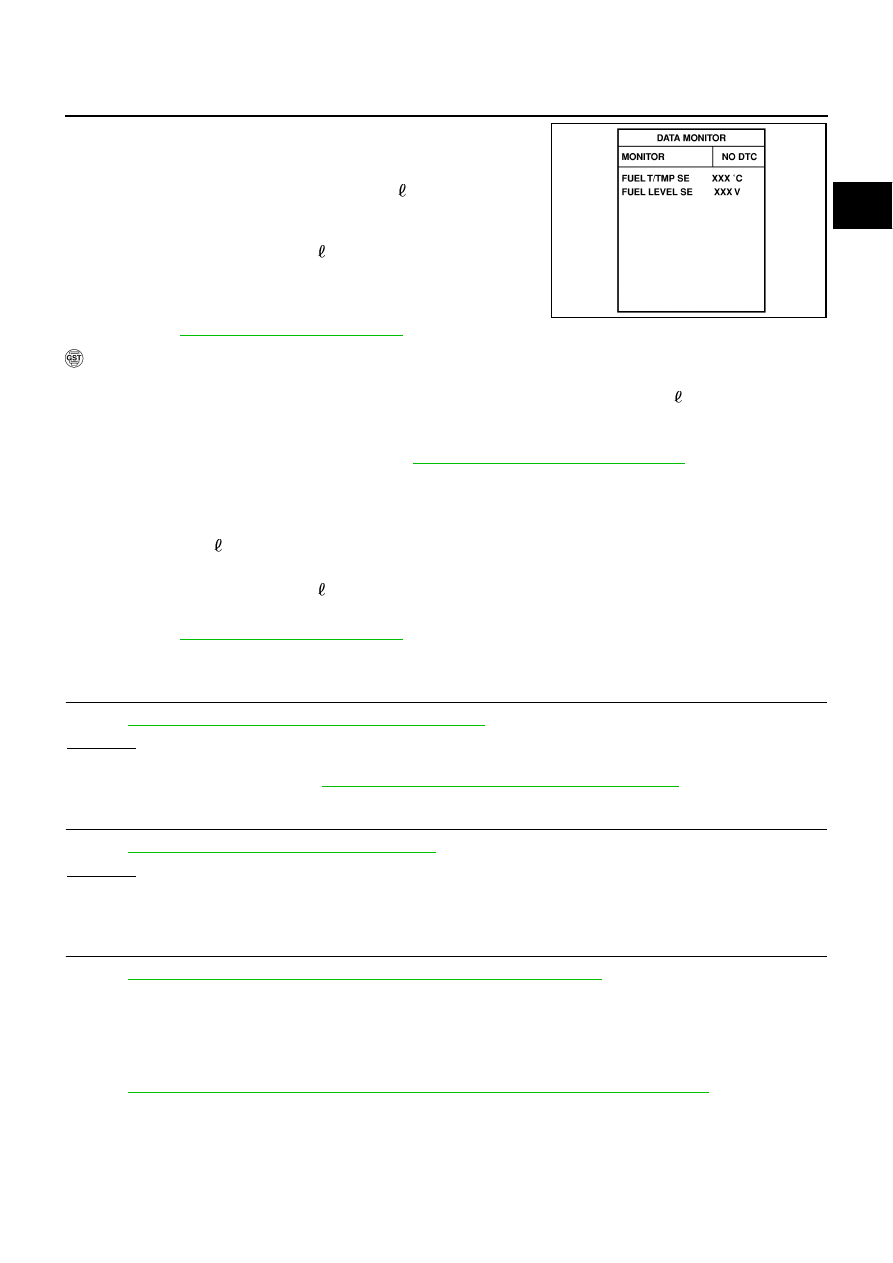

Check “FUEL LEVEL SE” output voltage and note it.

8.

Select “FUEL PUMP” in “ACTIVE TEST” mode with CONSULT-

II.

9.

Touch ON and drain fuel approximately 30 (7-7/8 US gal, 6-5/

8 Imp gal) and stop it.

10. Check “FUEL LEVEL SE” output voltage and note it.

11. Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

12. Check “FUEL LEVEL SE” output voltage and note it.

13. Confirm whether the voltage changes more than 0.03V during

step 7 to 10 and 10 to 12.

If NG, go to

EC-471, "Diagnostic Procedure"

WITH GST

NOTE:

Start from step 8, if it is possible to confirm that the fuel cannot be drained by 30 (7-7/8 US gal, 6-5/8

Imp gal) in advance.

1.

Prepare a fuel container and a spare hose.

2.

Release fuel pressure from fuel line. Refer to

EC-80, "FUEL PRESSURE RELEASE"

3.

Remove the fuel feed hose on the fuel level sensor unit.

4.

Connect a spare fuel hose where the fuel feed hose was removed.

5.

Turn ignition switch ON.

6.

Drain fuel by 30 (7-7/8 US gal, 6-5/8 Imp gal) from the fuel tank using proper equipment.

7.

Confirm that the fuel gauge indication varies.

8.

Fill fuel into the fuel tank for 30 (7-7/8 US gal, 6-5/8 Imp gal).

9.

Confirm that the fuel gauge indication varies.

EC-471, "Diagnostic Procedure"

Diagnostic Procedure

NBS001YB

1.

CHECK FUEL GAUGE OPERATION

Refer to

DI-16, "Self-Diagnosis Mode of Combination Meter"

.

OK or NG

OK

>> GO TO 2.

NG

DI-16, "Self-Diagnosis Mode of Combination Meter"

2.

CHECK FUEL LEVEL SENSOR AND CIRCUIT

Refer to

DI-20, "Fuel Level Sensor Signal Inspection"

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace malfunctioning parts.

3.

CHECK INTERMITTENT INCIDENT

Refer to

EC-145, "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT"

>> INSPECTION END

Removal and Installation

NBS001YC

FUEL LEVEL SENSOR

Refer to

FL-3, "FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY"

SEF195Y