Infiniti Q45. Manual - part 452

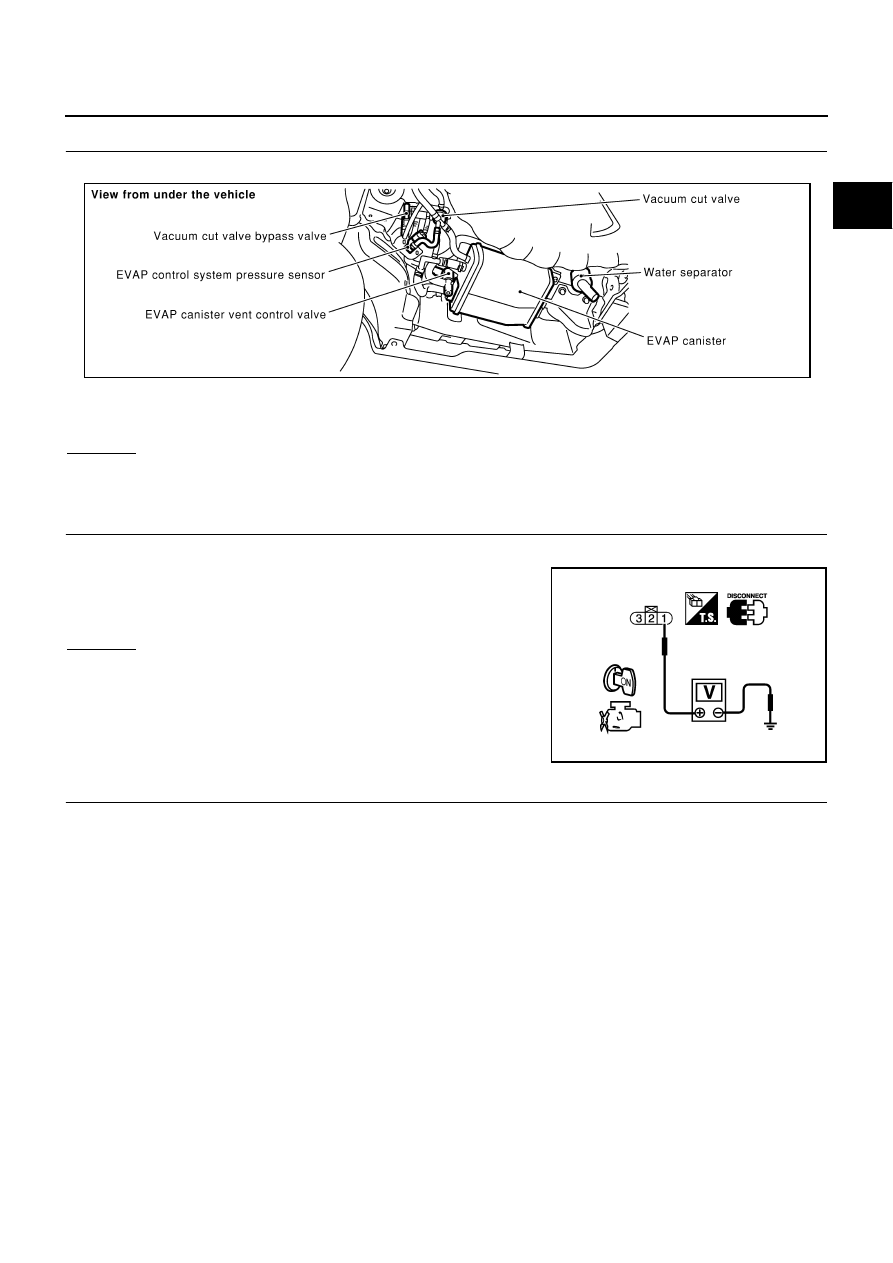

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-447

C

D

E

F

G

H

I

J

K

L

M

A

EC

2.

CHECK CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check sensor harness connector for water.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace harness connector.

3.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch ON.

2.

Check voltage between EVAP control system pressure sensor

terminal 1 and ground with CONSULT-II or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 4.

4.

DETECT MALFUNCTIONING PART

Check the following.

●

Harness connectors B401, B251

●

Harness connectors B211, M141

●

Harness connectors M135, F105

●

Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

Water should not exist.

PBIB0026E

Voltage: Approximately 5V

PBIB0155E