Infiniti Q45. Manual - part 392

DTC P0102, P0103 MAF SENSOR

EC-207

C

D

E

F

G

H

I

J

K

L

M

A

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic Procedure

NBS001ST

1.

INSPECTION START

Which malfunction (P0102 or P0103) is duplicated?

P0102 or P0103

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.

CHECK INTAKE SYSTEM

Check the following for connection.

●

Air duct

●

Vacuum hoses

●

Intake air passage between air duct and intake manifold

OK or NG

OK

>> GO TO 3.

NG

>> Reconnect the parts.

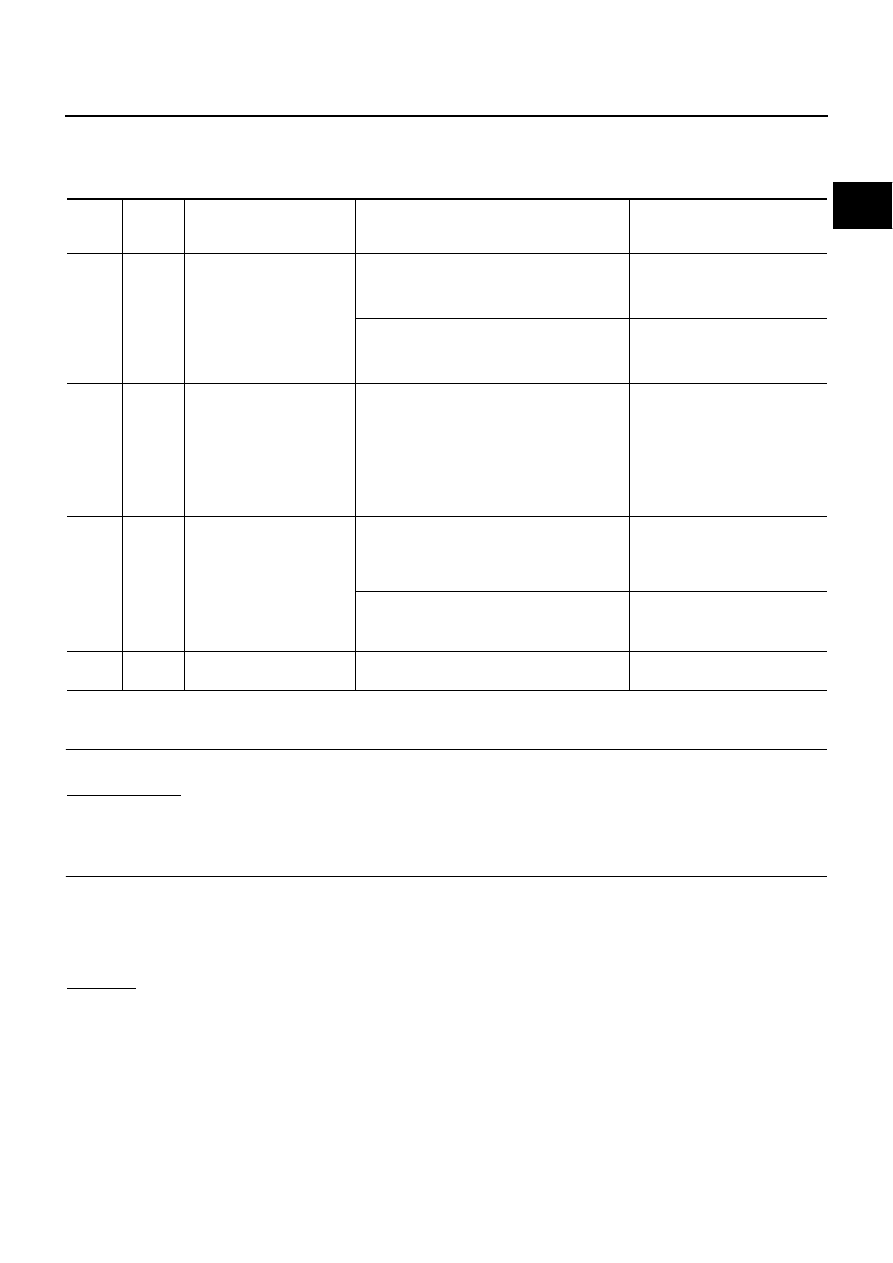

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

51

B/Y

Mass air flow sensor

[Engine is running]

●

Warm-up condition

●

Idle speed

1.0 - 1.2V

[Engine is running]

●

Warm-up condition

●

Engine speed: 2,500 rpm

1.6 - 1.9V

67

B

Sensor ground

(MAF sensor, IAT sensor,

ECT sensor, FTT sensor,

EVAP control system pres-

sure sensor, PSP sensor,

ICC steering switch, ASCD

steering switch, Refrigerant

pressure sensor)

[Engine is running]

●

Warm-up condition

●

Idle speed

Approximately 0V

111

W/B

ECM relay

(Self shut-off)

[Engine is running]

[Ignition switch: OFF]

●

For a few seconds after turning ignition

switch OFF

0 - 1.5V

[Ignition switch: OFF]

●

More than a few seconds after turning igni-

tion switch OFF

BATTERY VOLTAGE

(11 - 14V)

119

120

R

R

Power supply for ECM

[Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14V)