Infiniti M45 (Y34). Manual - part 556

COIL SPRING AND STRUT

FSU-11

C

D

F

G

H

I

J

K

L

M

A

B

FSU

ASSEMBLY

CAUTION:

Make sure piston rod on strut assembly is not damaged when attaching components to strut assem-

bly.

1.

Install strut attachment (special service tool) to strut assembly and fix it in a vice.

CAUTION:

When installing strut attachment (special service tool) to strut assembly, wrap a shop cloth around

strut assembly to protect it from damage.

2.

Compress coil spring using a spring compressor (commercial service tool), and install it onto strut assem-

bly.

CAUTION:

●

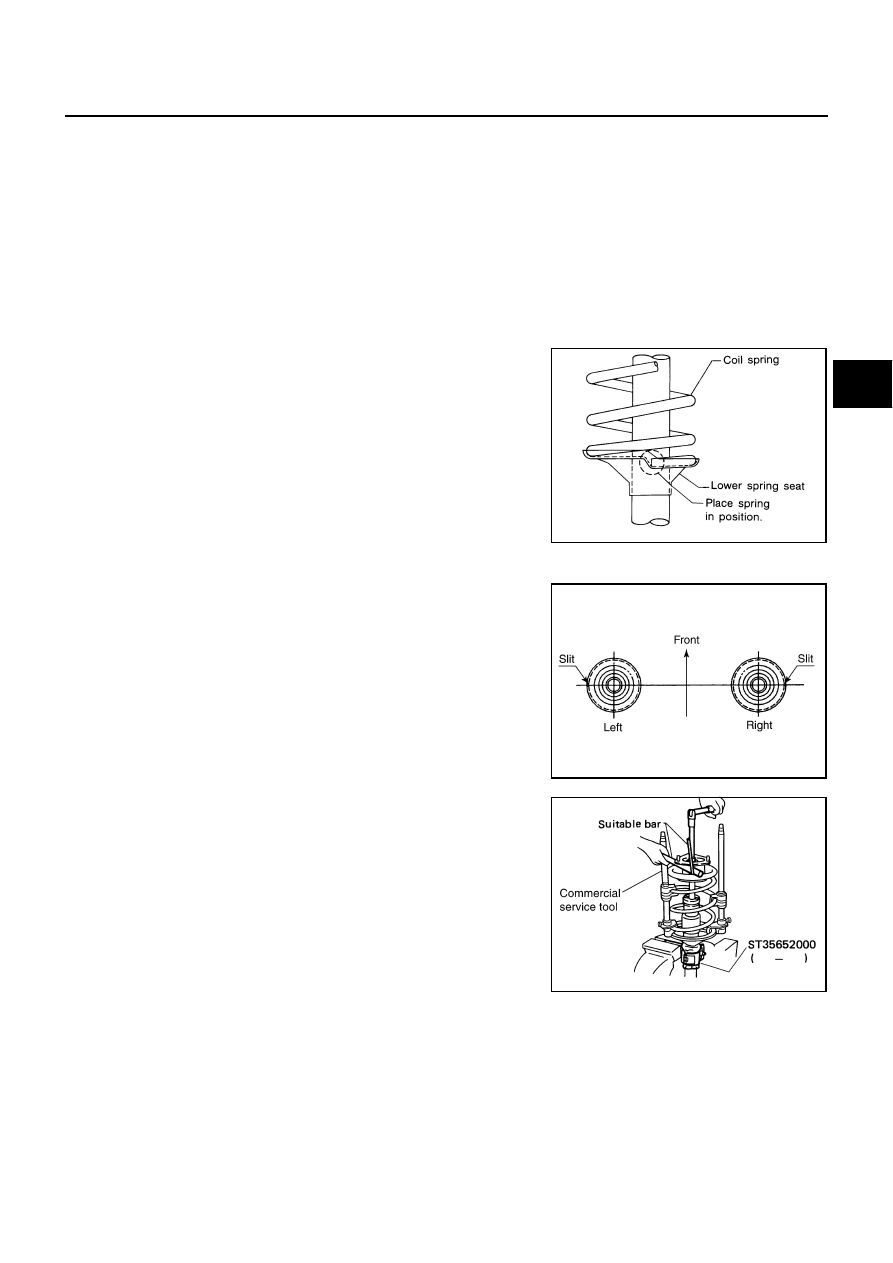

Face tube side of coil spring downward. Align lower end

to spring seat as shown in the figure.

●

Be sure spring compressor (commercial service tool) is

securely attached to coil spring. Compress coil spring.

3.

Apply soapy water to bound bumper and insert into strut mount-

ing insulator.

CAUTION:

Do not use machine oil.

4.

Install rubber seat, spring upper seat, strut mounting insulator.

●

Installation position of spring upper seat is as shown in the fig-

ure.

5.

Fix strut mounting insulator, then tighten piston rod lock nut with

the specified torque.

CAUTION:

Be careful not to deform strut mounting insulator.

6.

Gradually release spring compressor (commercial service tool),

and remove coil spring.

CAUTION:

Loosen while making sure coil spring attachment position

does not move.

7.

Remove strut attachment (special service tool) from strut

assembly.

SFA149

SEIA0247E

SEIA0298E