Infiniti M45 (Y34). Manual - part 461

DTC P1229 SENSOR POWER SUPPLY

EC-533

C

D

E

F

G

H

I

J

K

L

M

A

EC

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

Diagnostic Procedure

ABS002QC

1.

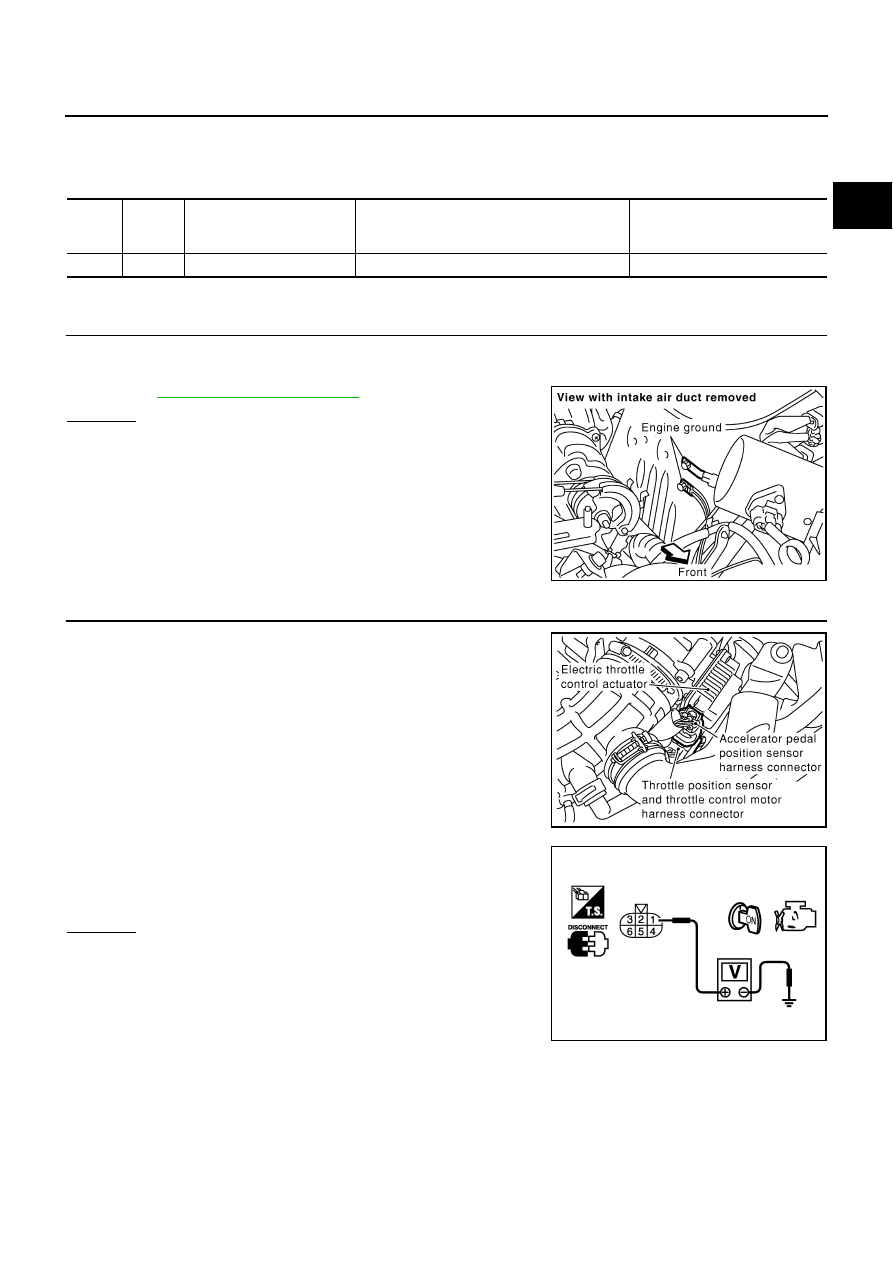

CHECK GROUND CONNECTIONS

1.

Turn ignition switch OFF.

2.

Loosen and retighten two ground screws.

Refer to

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

CHECK THROTTLE POSITION SENSOR POWER SUPPLY CIRCUIT

1.

Disconnect electric throttle control actuator harness connector.

2.

Turn ignition switch ON.

3.

Check voltage between electric throttle control actuator terminal

1 and ground with CONSULT-II or tester.

OK or NG

OK

>> GO TO 5.

NG

>> GO TO 3.

TER-

MINAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

103

L

Sensor power supply

[Ignition switch: ON]

Approximately 5V

PBIB1118E

PBIB0015E

Voltage: Approximately 5V

PBIB0082E