Infiniti F50. Manual - part 821

ELECTRICALLY CONTROLLED POWER STEERING SYSTEM

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

M

A

B

STC

10.

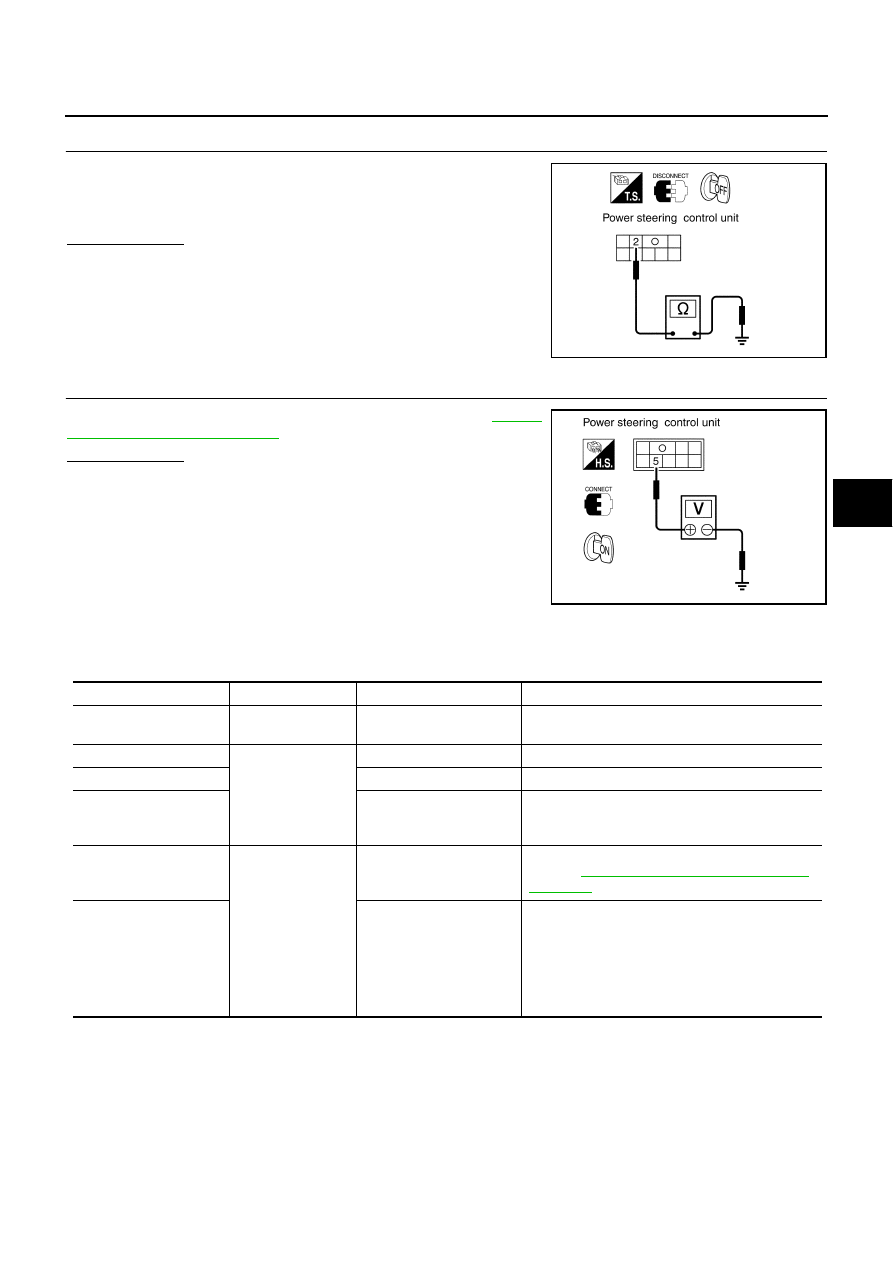

POWER STEERING CONTROL UNIT GROUND INSPECTION

Check for continuity between the power steering control unit terminal

2 (B) and body ground.

Is the result OK?

OK

>> GO TO 11.

NG

>> Repair or replace harness.

11.

ENGINE REVOLUTION SIGNAL INSPECTION

Check power steering control unit terminal 5 (W/G),. Refer to

"Control Unit Inspection Table"

.

Is the result OK?

OK

>> GO TO 1.

NG

>> Check harness between ECM and control unit or ECM.

Repair or replace harness if necessary.

Control Unit Inspection Table

EGS0007Z

The standard values (voltage), measured with an analog tester in contact with control unit terminal, are shown

below:

2 (B) - Body ground

: Continuity should exist

SGIA0051E

SGIA0052E

Inspection terminal

Condition

Application

Standard

Power steering control

unit

1

Ignition switch ON

Power

Battery voltage (approx. 12V)

2

Ground

0V

3

Vehicle speed signal

When the speed is very low, the voltage fluctuates

between approximately 0V and approximately 5V

or higher.

5

Engine running

Engine revolution signal

Measure the tachometer drive signal.

Refer to

EC-99, "ECM Harness Connector Termi-

7

Solenoid valve

Normal

0 km/h ((0 MPH)

: Approx. 4.4 - 6.6V

100 km/h (62 MPH): Approx. 2.4 - 3.6V

When the fail-safe function is activated:

0 - 1,500 rpm

: Approx. 4.4 - 6.6V

1,500 - 3,000 rpm : Approx. 3.5V

3,000 rpm or more: Approx. 2.1V