Infiniti F50. Manual - part 768

AUTOMATIC DRIVE POSITIONER

SE-63

C

D

E

F

G

H

J

K

L

M

A

B

SE

3.

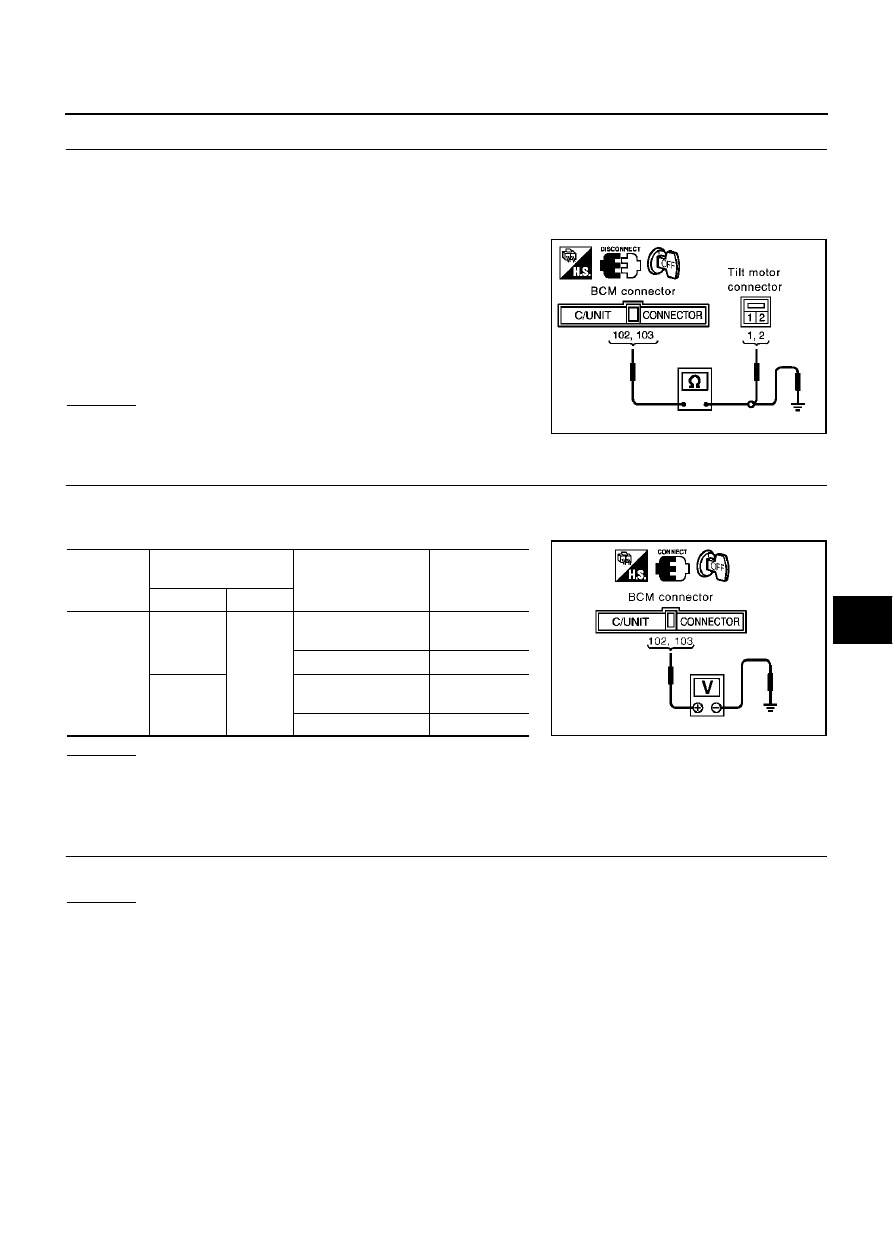

CHECK HARNESS CONTINUITY

1.

Turn ignition switch OFF.

2.

Disconnect BCM connector and tilt motor connector.

3.

Check continuity between BCM connector M4 terminals 102 (P), 103 (R/B) and tilt motor connector M58

terminals 1 (R/B), 2 (P).

4.

Check continuity between BCM connector M4 terminals 102 (P),

103 (R/B) and ground.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace harness between BCM and tilt motor.

4.

CHECK BCM OUTPUT SIGNAL

1.

Connect BCM connector and tilt motor connector.

2.

Check voltage between BCM connector.

OK or NG

OK

>> Replace tilt motor.

NG

>> Replace BCM.

Seat Sliding Sensor Circuit Inspection

EIS0041T

1.

CHECK SLIDING SENSOR MECHANISM

Check the operation malfunction caused by sliding rail deformation or parts are loose.

OK or NG

OK

>> GO TO 2.

NG

>> Repair the malfunctioning part and check again.

102 (P) – 2 (P)

: Continuity should exist.

103 (R/B) – 1 (R/B)

: Continuity should exist.

102 (P) – Ground

:Continuity should not exist.

103 (R/B) – Ground

:Continuity should not exist.

PIIA3266E

Connector

Terminals

(Wire color)

Condition

Voltage (V)

(Approx.)

(+)

(–)

M4

102 (P)

Ground

Tilt switch

(DOWN operation).

Battery voltage

Tilt switch OFF.

0

103 (R/B)

Tilt switch

(UP operation).

Battery voltage

Tilt switch OFF.

0

PIIA4385E