Infiniti F50. Manual - part 545

CYLINDER HEAD

EM-67

C

D

E

F

G

H

I

J

K

L

M

A

EM

2.

Drive out valve guide with a press [under a 20 kN (2 ton, 2.2 US

ton, 2.0 lmp ton) pressure] or hammer and suitable tool.

CAUTION:

Cylinder head contains heat, when working wear protective

equipment to avoid getting burned.

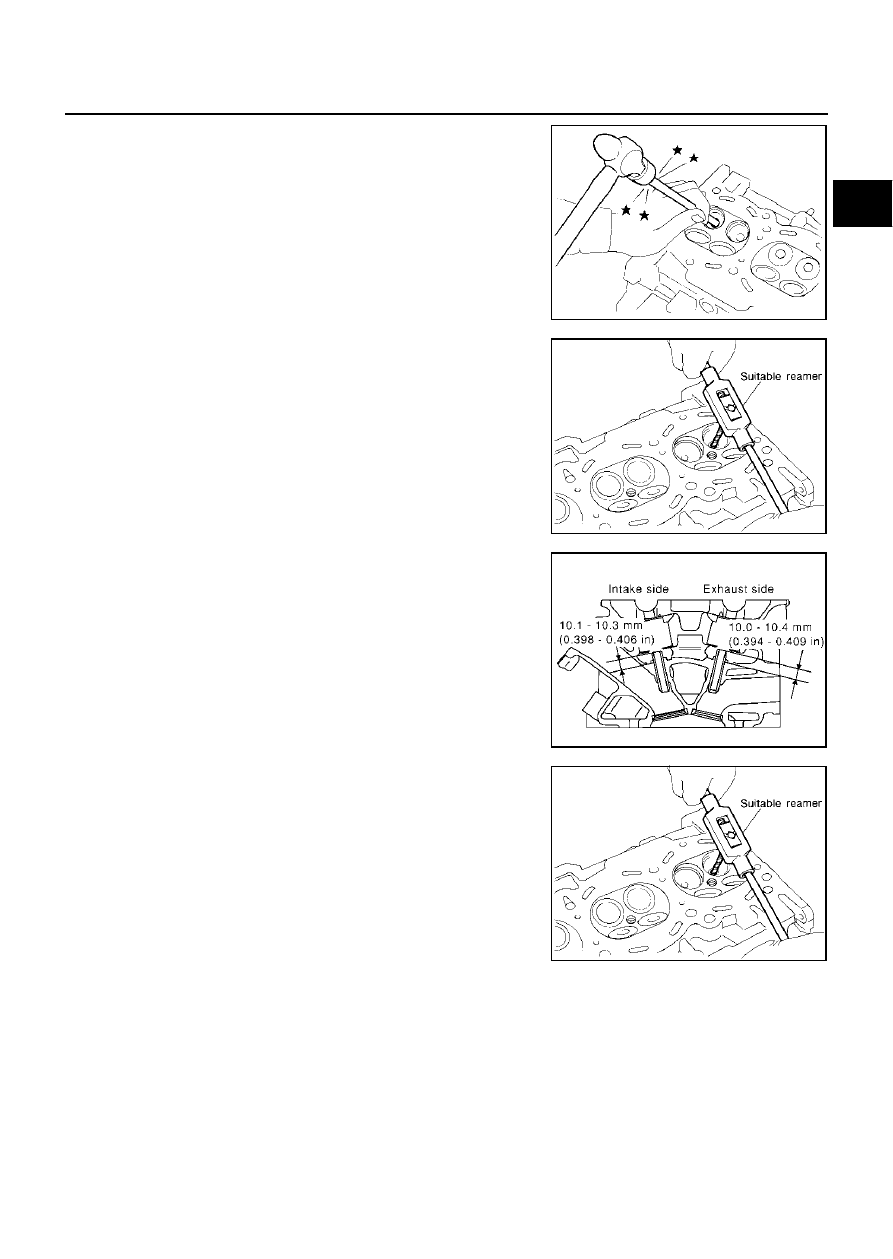

3.

Ream cylinder head valve guide hole.

4.

Heat cylinder head to 110 to 130

°

C (230 to 266

°

F) by soaking in

heated oil.

5.

Press valve guide from camshaft side to dimensions as in illus-

tration.

CAUTION:

Cylinder head contains heat, when working wear protective

equipment to avoid getting burned.

6.

Using valve guide reamer, apply reamer finish to valve guide.

SEM931C

Valve guide hole diameter (for service parts)

Intake and exhaust:

10.175 - 10.196 mm (0.4006 - 0.4014 in)

SEM932C

PBIC0078E

Standard

Intake and exhaust:

6.000 - 6.018 mm (0.2362 - 0.2369 in)

SEM932C