Infiniti F50. Manual - part 435

DTC P0456 EVAP CONTROL SYSTEM

EC-381

C

D

E

F

G

H

I

J

K

L

M

A

EC

10.

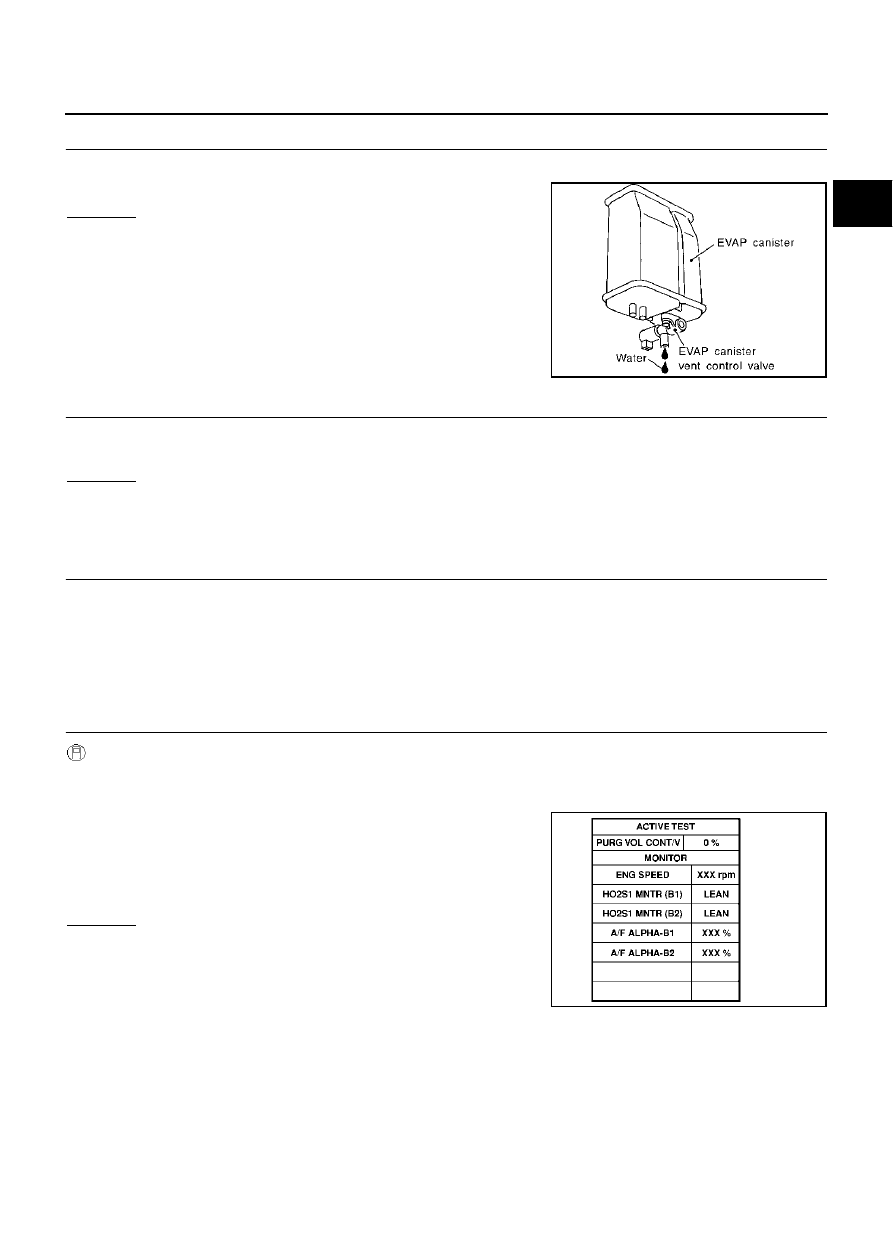

CHECK IF EVAP CANISTER SATURATED WITH WATER

1.

Remove EVAP canister with EVAP canister vent control valve attached.

2.

Does water drain from the EVAP canister?

Yes or No

Yes

>> GO TO 11.

No (With CONSULT-II)>>GO TO 13.

No (Without CONSULT-II)>>GO TO 14.

11.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve attached.

The weight should be less than 1.8 kg (4.0 lb).

OK or NG

OK (With CONSULT-II)>>GO TO 13.

OK (Without CONSULT-II)>>GO TO 14.

NG

>> GO TO 12.

12.

DETECT MALFUNCTIONING PART

Check the following.

●

EVAP canister for damage

●

EVAP hose between EVAP canister and water separator for clogging or poor connection

>> Repair hose or replace EVAP canister.

13.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1.

Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2.

Start engine.

3.

Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode.

4.

Touch “Qu” on CONSULT-II screen to increase “PURG VOL

CONT/V” opening to 100.0%.

5.

Check vacuum hose for vacuum when revving engine up to

2,000 rpm.

OK or NG

OK

>> GO TO 16.

NG

>> GO TO 15.

SEF596U

PBIB0147E