Infiniti F50. Manual - part 276

TROUBLE DIAGNOSIS

BRC-47

C

D

E

G

H

I

J

K

L

M

A

B

BRC

3.

CHECKING YAW RATE/SIDE G-SENSOR CIRCUIT

Check “DATA MONITOR” for yaw rate /side G-sensor. Check that results are normal.

OK or NG

OK

>> Perform VDC/TCS/ABS control unit self-diagnosis again.

NG

>> Malfunction of yaw rate/side G-sensor. Replace sensor and perform VDC/TCS/ABS control unit

self-diagnosis again.

Inspection 7 Solenoid, VDC Switching Valve, and Circuits

EFS0023W

Inspection Procedure

1.

CHECKING SELF-DIAGNOSIS RESULTS (1)

Check self-diagnosis results.

Do above items appear on self-diagnosis results display?

YES

>> GO TO 2.

NO

>> Inspection is completed.

2.

CHECKING SELF-DIAGNOSIS RESULTS (2)

1.

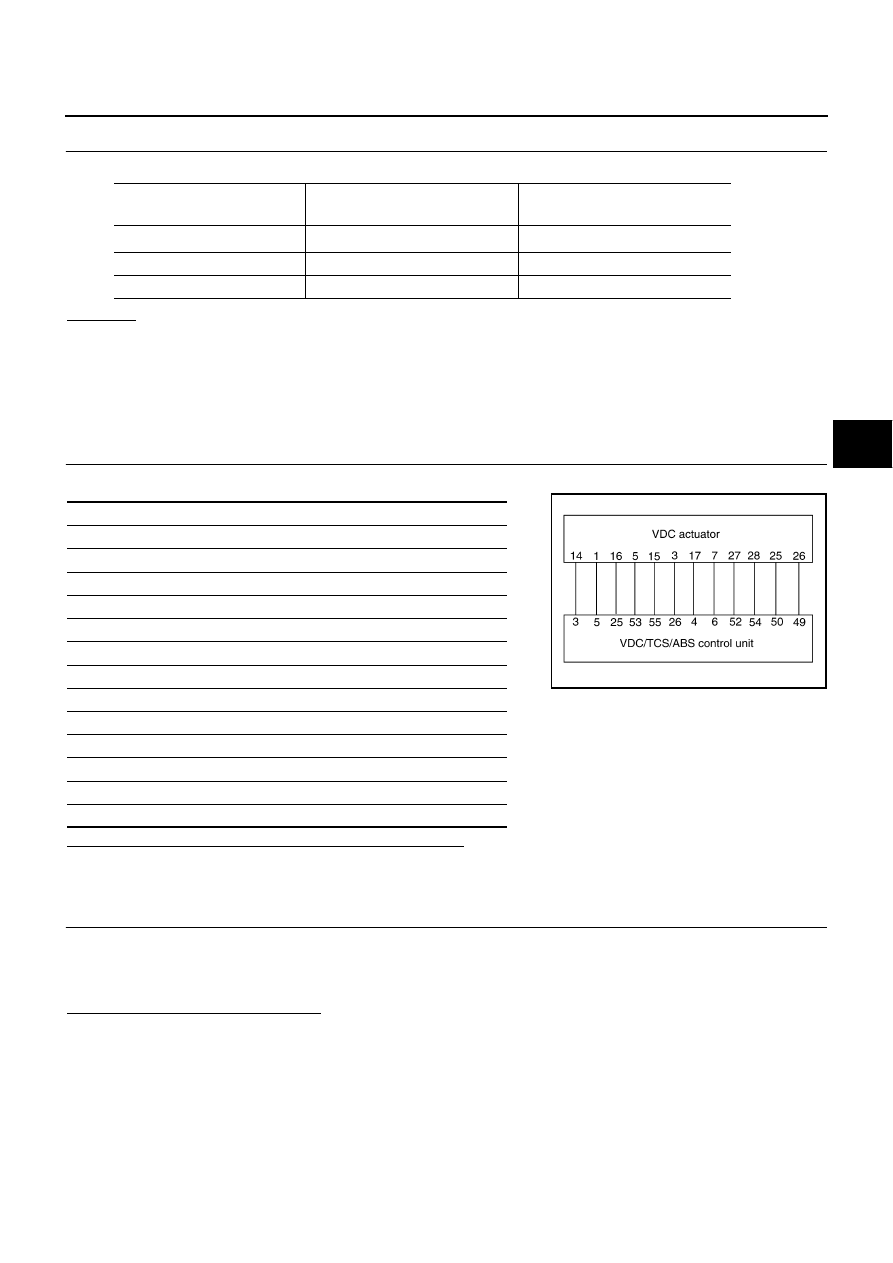

Disconnect VDC/TCS/ABS control unit connector E218 and VDC actuator connector E21, E22, E23.

Then reconnect them securely.

2.

Reconnect connectors securely and perform self-diagnosis again.

Do any self-diagnosis items appear?

YES

>> GO TO 3.

NO

>> Poor connection. Repair or replace applicable connector.

Vehicle condition

Yaw rate sensor

(Data monitor standard)

Side G-sensor

(Data monitor standard)

Stopped

– 4 to +4 deg/s

– 1.1 to +1.1 m/s

2

Turning right

Negative value

Negative value

Turning left

Positive value

Positive value

Self-diagnosis results

CONSULT-II display items

Front LH inlet ABS solenoid system

Front LH outlet ABS solenoid system

Rear RH inlet ABS solenoid system

Rear RH outlet ABS solenoid system

Front RH inlet ABS solenoid system

Front RH outlet ABS solenoid system

Rear LH inlet ABS solenoid system

Rear LH outlet ABS solenoid system

Primary USV solenoid system

Secondary USV solenoid system

Primary MAV solenoid system

Secondary MAV solenoid system

SFIA0611E