Infiniti F50. Manual - part 50

TROUBLE DIAGNOSIS

AT-85

D

E

F

G

H

I

J

K

L

M

A

B

AT

12

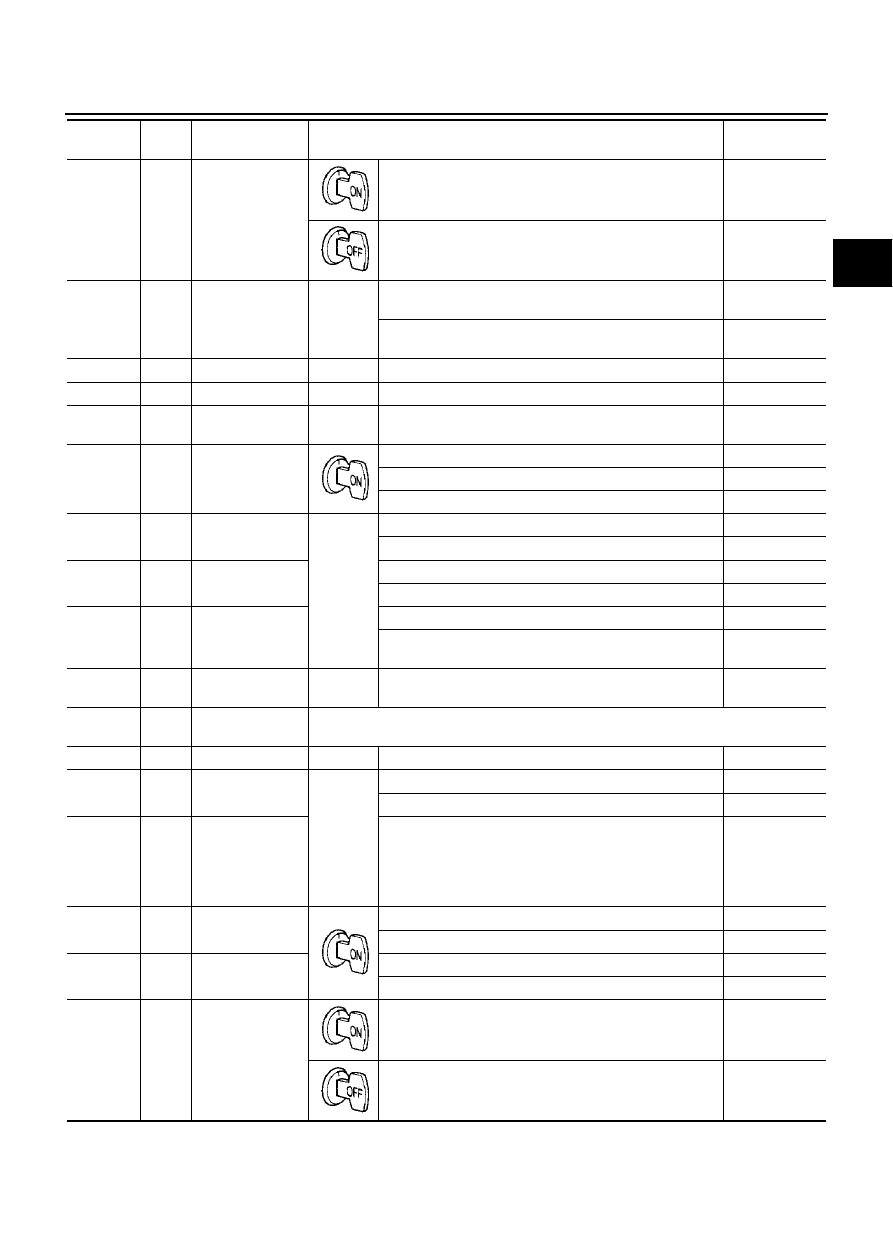

Y/R

Power supply

(out)

–

Battery voltage

–

0V

13

W/L

Low coast brake

solenoid valve

When

vehicle

cruises

When the solenoid valve is operating (when running in M1-

1 gear or M2-2 gear)

Battery voltage

When the solenoid valve is not operating (when running in

“D”)

0V

14

B

Ground

–

–

–

15

B/W

SEL4

–

–

–

16

W/G

SEL1 (pressure

switch 2)

–

–

–

17

Y/B

Fluid temperature

sensor 2

When ATF temperature about 0

°

C (32

°

F)

2.2V

When ATF temperature about 20

°

C (68

°

F)

1.7V

When ATF temperature about 80

°

C (176

°

F)

0.45V

19

R

Front brake sole-

noid valve

When

vehicle

cruises

When the solenoid valve is operating (other than 4th gear)

More than 2V

When the solenoid valve is not operating (4th gear)

0V

20

Y

TCC solenoid

valve

When lock-up

More than 2V

When not lock-up

0V

21

G

Direct clutch sole-

noid valve

When the solenoid valve is operating (1st gear or 5th gear)

More than 2V

When the solenoid valve is not operating (2nd gear, 3rd

gear, or 4th gear)

0V

22

P/B

SEL2 (pressure

switch 5)

–

–

–

23

PU/W

K-line (CONSULT-

II signal)

The terminal is connected to the data link connector for CONSULT-II.

24

B

Ground

–

–

–

26

G/Y

PSC2 (pressure

switch 6)

When

vehicle

cruises

When high and low reverse clutch solenoid valve “ON”.

0V

When high and low reverse clutch solenoid valve “OFF”.

Battery voltage

27

Y/B

Vehicle speed

sensor A/T (revo-

lution sensor)

When moving at 20 km/h (12 MPH), use the CONSULT-II

pulse frequency measuring function.

CAUTION:

Connect the data link connector to the vehicle-side

diagnosis connector.

185 (Hz)

30

R/W

PNP switch 1

Selector lever in “P” position.

Battery voltage

Selector lever in “N” position.

Less than 2.5V

31

OR

PNP switch 2

Selector lever in “P” position.

Battery voltage

Selector lever in “D” position.

Less than 2.5V

33

G/R

Power supply

–

Battery voltage

–

0V

Terminal

No.

Wire

color

Item

Condition

Data (Approx.)