Infiniti G37 Coupe. Manual - part 752

HA-54

< ON-VEHICLE REPAIR >

EVAPORATOR

Removal and Installation

INFOID:0000000001675654

REMOVAL

1.

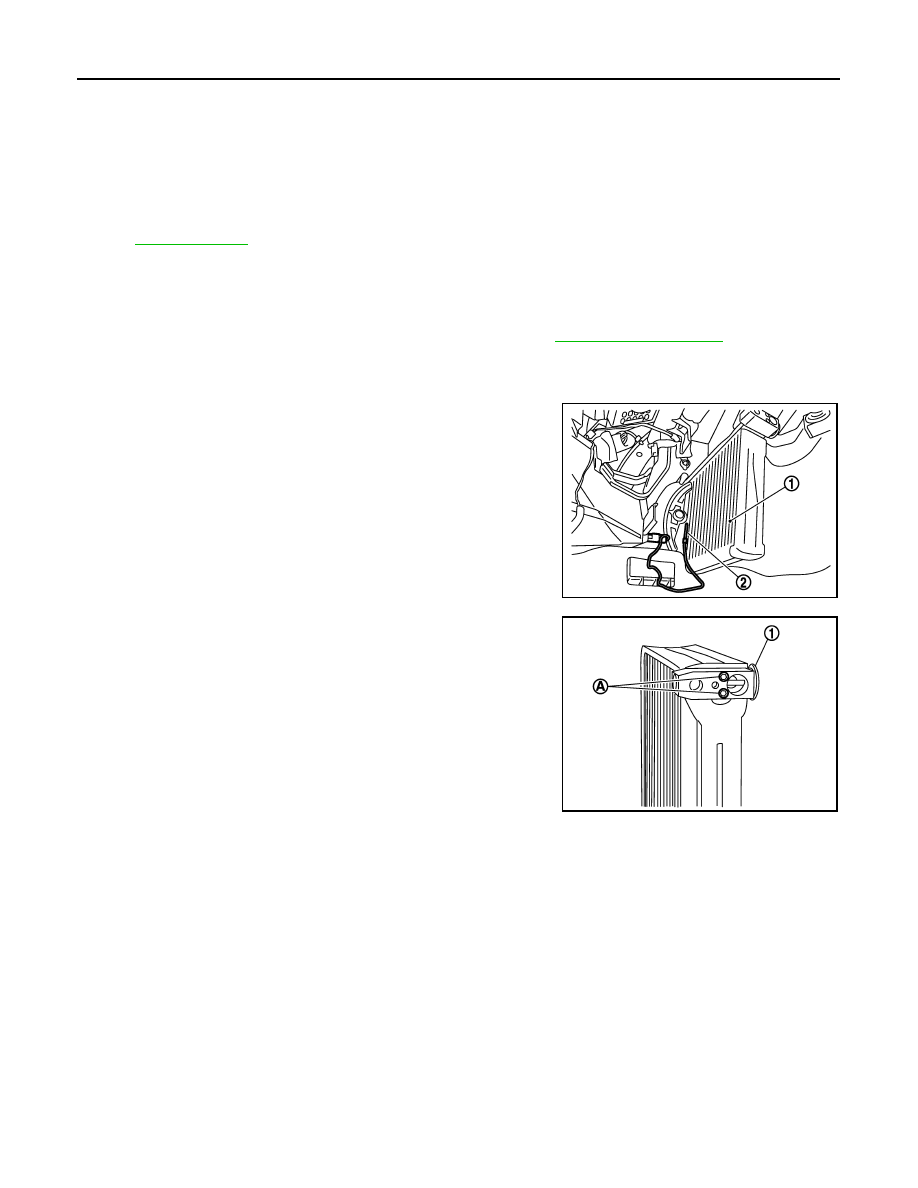

Remove low-pressure pipe 1 and high-pressure pipe 2. Refer to

CAUTION:

Cap or wrap the joint of the A/C piping and expansion valve with suitable material such as vinyl

tape to avoid the entry of air.

2.

Slide evaporator (1) from heater & cooling unit assembly.

3.

Remove intake sensor (2) from evaporator, and then remove

evaporator.

4.

Remove mounting bolts (A), and then remove expansion valve

(1).

CAUTION:

Cap or wrap the joint of evaporator and expansion valve

with suitable material such as vinyl tape to avoid the entry

of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• O-rings differ from low-pressure flexible hose (high-pressure pipe 1) and low-pressure pipe 1 (high-

pressure pipe 2).

• Mark the mounting position of intake sensor bracket prior to removal so that the reinstalled sensor

can be located in the same position.

• Check for leakages when recharging refrigerant.

37. Max. cool door lever

38.

Foot door link

39.

Defroster door link

40. Max. cool door link

41.

Main link sub

42.

Evaporator cover

43. Heater & cooling unit case (right)

44.

Evaporator

45.

Drain hose

46. Clamp

47.

Air mix door (Slide door)

48.

Air mix door adapter

49. Heater pipe cover

50.

Max. cool door (left)

51.

Defroster door (left)

52. Center case

53.

Defroster door (right)

54.

Max. cool door (right)

*

With left and right ventilation temperature separately system.

for symbols in the figure.

JSIIA0052ZZ

JSIIA0102ZZ