Infiniti G37 Coupe. Manual - part 628

CAMSHAFT

EM-87

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

2.

Install oil filter (1), if removed.

• Do not project from the cylinder head (2) surface.

3.

Install valve lifter.

• Install it in the original position.

4.

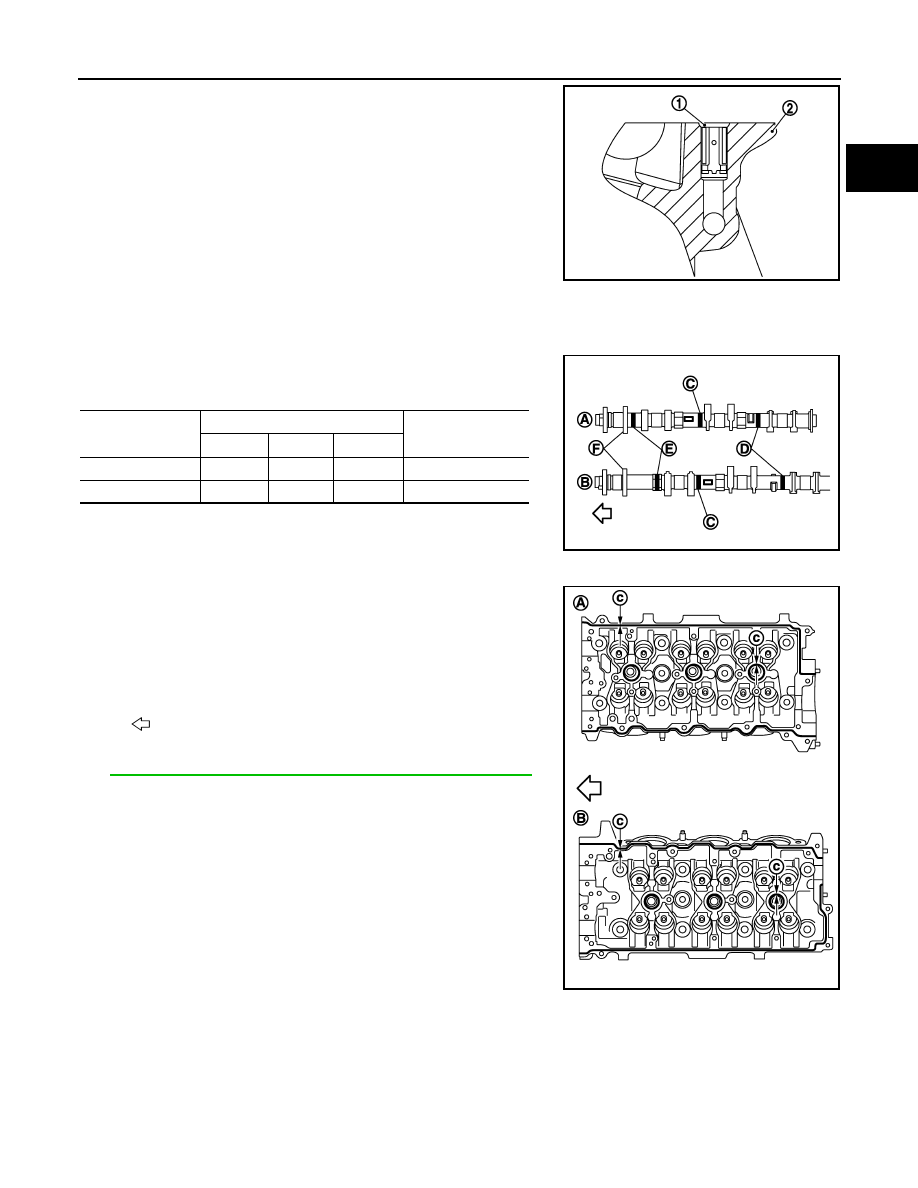

Install camshaft (EXH).

• Distinction between camshaft (EXH) (bank 1 and bank 2) is

performed with the identification mark.

5.

Install VVEL ladder assembly as follows:

a.

Apply a continuous bead of liquid gasket with tube presser

(commercial service tool) to the cylinder head as shown in the

figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "Recommended Chemical Products and Sealants"

.

JPBIA1390ZZ

Bank

Paint marks

Identification mark

(F)

M1 (C)

M2 (D)

M3 (E)

Bank 1 (A)

No

Blue

Light blue

1N

Bank 2 (B)

No

Blue

Light blue

1P

JPBIA1129ZZ

A

: Bank 1

B

: Bank 2

c

: 3.4 - 4.4 mm (0.134 - 0.173 in) dia

: Engine front

JPBIA1123ZZ