Infiniti G37 Coupe. Manual - part 610

SPARK PLUG

EM-15

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

SPARK PLUG

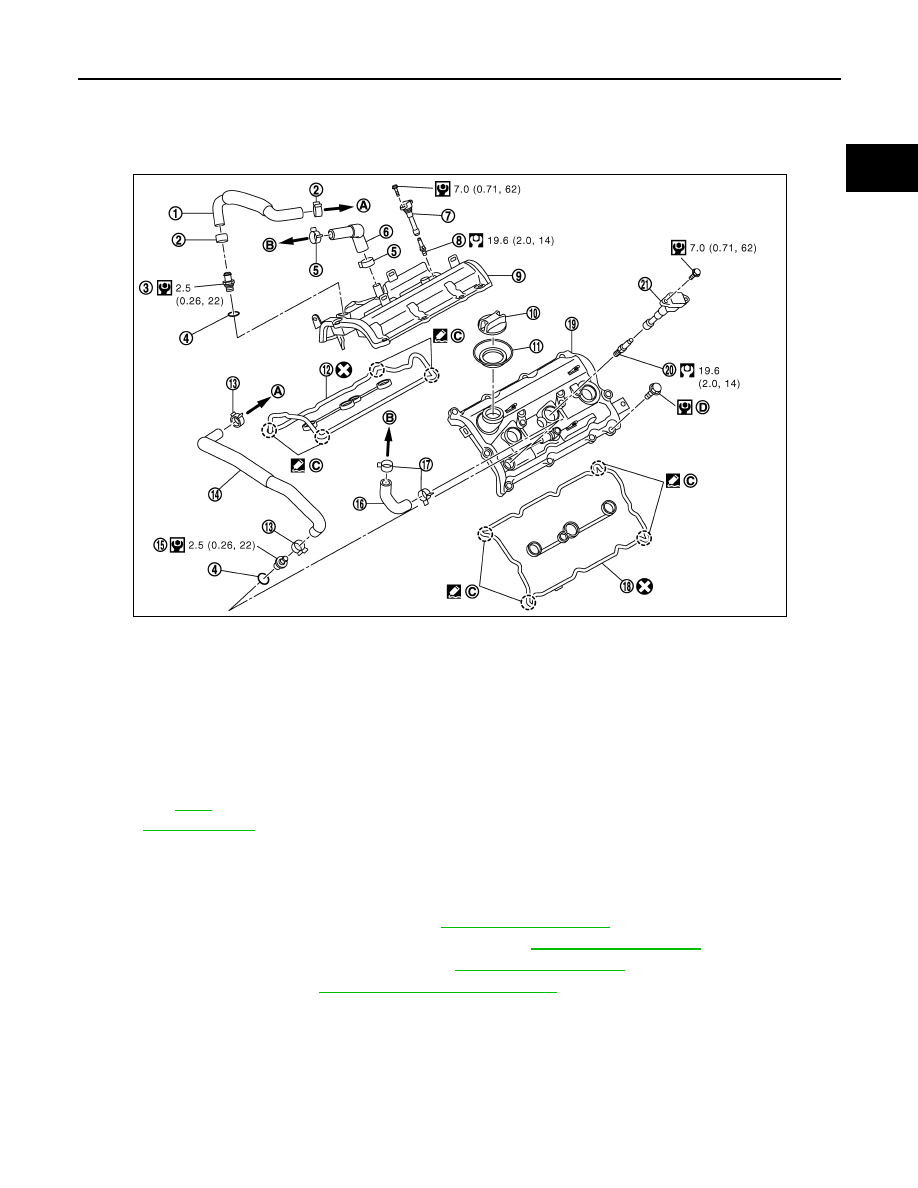

Exploded View

INFOID:0000000001547615

Removal and Installation

INFOID:0000000001547616

REMOVAL

1.

Remove engine cover with power tool. Refer to

.

2.

Remove air cleaner case and air duct (RH and LH). Refer to

.

3.

Remove electric throttle control actuator. Refer to

.

4.

Remove ignition coil. Refer to

EM-45, "Removal and Installation"

.

1.

PCV hose

2.

Clamp

3.

PCV valve

4.

O-ring

5.

Clamp

6.

PCV hose

7.

Ignition coil

8.

Spark plug

9.

Rocker cover (bank 1)

10.

Oil filler cap

11.

Oil catcher

12. Rocker cover gasket (bank 1)

13.

Clamp

14.

PCV hose

15. PCV valve

16.

PCV hose

17.

Clamp

18. Rocker cover gasket (bank 2)

19.

Rocker cover (bank 2)

20.

Spark plug

21. Ignition coil

A.

To intake manifold collector

B.

To air duct

C.

VVEL ladder assembly side

D.

Refer to

Refer to

for symbols in the figure.

JPBIA1174GB