Infiniti G37 Coupe. Manual - part 452

DLN-122

< DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R200V]

DRIVE PINION

12. Select the correct pinion height adjusting washer.

13. Remove the J-34309 differential shim selector tool from the final

drive housing. Then disassemble to retrieve the pinion bearings.

COMPANION FLANGE RUNOUT

1.

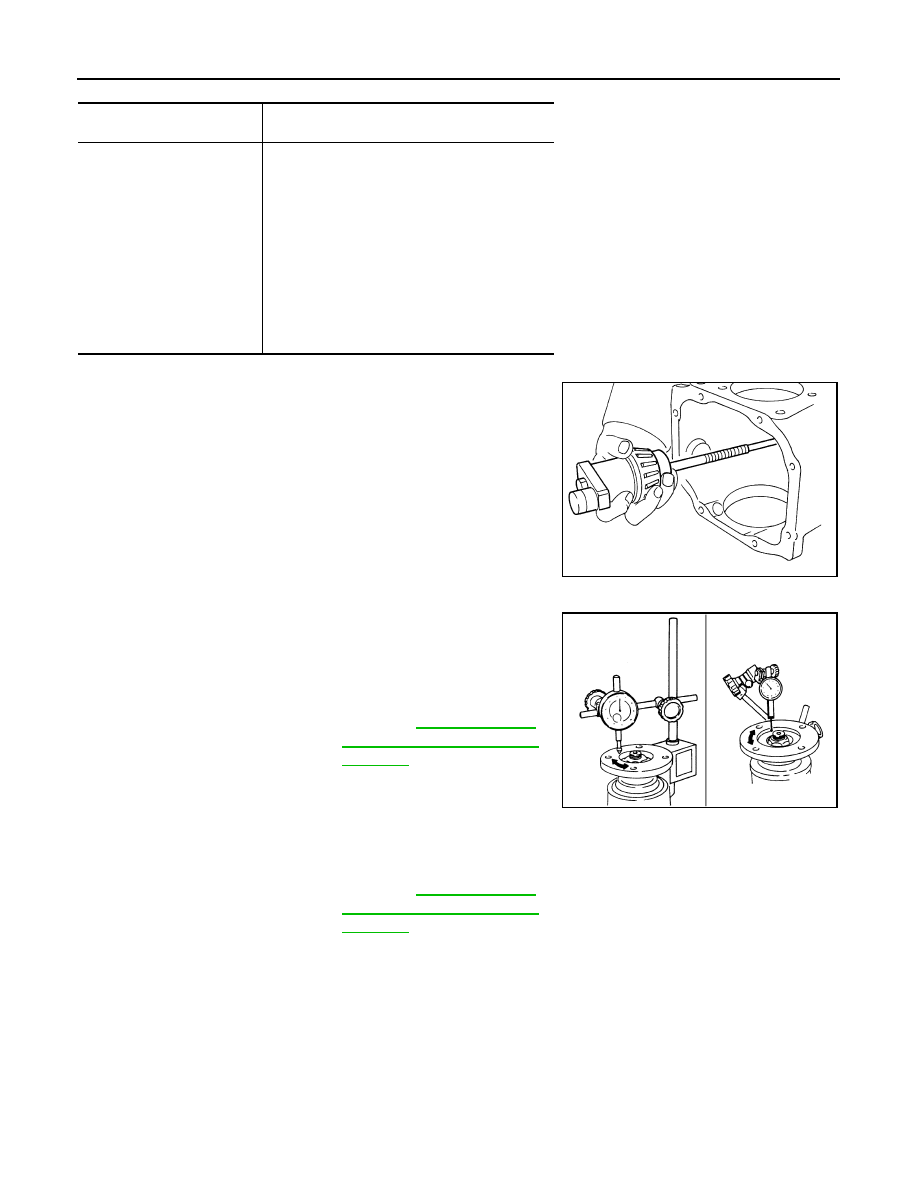

Fit a dial indicator onto the companion flange face (inner side of

the propeller shaft mounting bolt holes).

2.

Rotate the companion flange to check for runout.

3.

Fit a test indicator to the inner side of the companion flange

(socket diameter).

4.

Rotate the companion flange to check for runout.

5.

If the runout value is outside the repair limit, follow the procedure below to adjust.

a.

Check for runout while changing the phase between companion flange and drive pinion gear by 90

°

step,

and search for the position where the runout is the minimum.

b.

If the runout value is still outside of the limit after the phase has been changed, possible causes are an

assembly malfunction of drive pinion and pinion bearing and malfunction of pinion bearing. Check for

these items and repair if necessary.

c.

If the runout value is still outside of the limit after the check and repair, replace companion flange.

Pinion head height number

Add or remove from the standard pinion height ad-

justing washer thickness measurement

−

6

−

5

−

4

−

3

−

2

−

1

0

+1

+2

+3

+4

+5

+6

Add 0.06 mm (0.0024 in)

Add 0.05 mm (0.0020 in)

Add 0.04 mm (0.0016 in)

Add 0.03 mm (0.0012 in)

Add 0.02 mm (0.0008 in)

Add 0.01 mm (0.0004 in)

Use the selected washer thickness

Subtract 0.01 mm (0.0004 in)

Subtract 0.02 mm (0.0008 in)

Subtract 0.03 mm (0.0012 in)

Subtract 0.04 mm (0.0016 in)

Subtract 0.05 mm (0.0020 in)

Subtract 0.06 mm (0.0024 in)

SPD205A

Limit

Companion flange runout

: Refer to

panion flange Runout (M/T

Models)"

.

Limit

Companion flange runout

: Refer to

panion flange Runout (M/T

Models)"

.

JSDIA0116ZZ