Infiniti G37 Coupe. Manual - part 265

BRC-34

< COMPONENT DIAGNOSIS >

[VDC/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

C1105, C1106, C1107, C1108 WHEEL SENSOR-2

Description

INFOID:0000000001665608

When the sensor rotor rotates, the magnetic field changes. It converts the magnetic field changes to current

signals (rectangular wave) and transmits them to the ABS actuator and electric unit (control unit).

DTC Logic

INFOID:0000000001635046

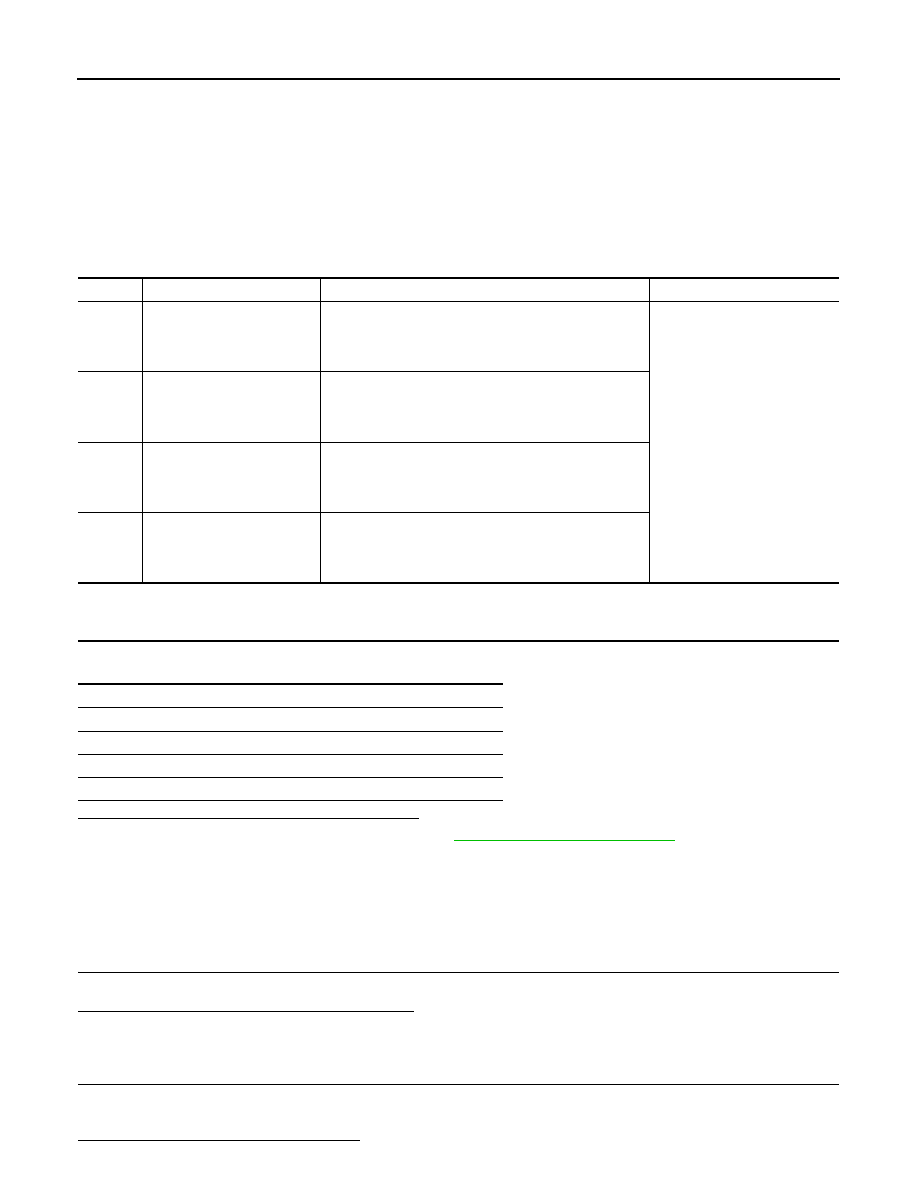

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000001665605

CAUTION:

Do not check between wheel sensor terminals.

1.

CHECK TIRES

Check air pressure, wear and size.

Are air pressure, wear and size within standard?

YES

>> GO TO 2.

NO

>> Adjust air pressure, or replace tire.

2.

CHECK SENSOR AND SENSOR ROTOR

• Check sensor rotor for damage.

• Check wheel sensor for damage, disconnection or looseness.

Are the sensor and sensor rotor normal?

DTC

Display item

Malfunction detected condition

Possible cause

C1105

RR RH SENSOR-2

When the circuit in the rear RH wheel sensor is short-cir-

cuited. Or when the distance between the wheel sensor

and sensor rotor is too large and the sensor pulse cannot

be recognized by the control unit.

• Harness or connector

• Wheel sensor

• ABS actuator and electric unit

(control unit)

C1106

RR LH SENSOR-2

When the circuit in the rear LH wheel sensor is short-cir-

cuited. Or when the distance between the wheel sensor

and sensor rotor is too large and the sensor pulse cannot

be recognized by the control unit.

C1107

FR RH SENSOR-2

When the circuit in the front RH wheel sensor is short-cir-

cuited. Or when the distance between the wheel sensor

and sensor rotor is too large and the sensor pulse cannot

be recognized by the control unit.

C1108

FR LH SENSOR-2

When the circuit in the front LH wheel sensor is short-cir-

cuited. Or when the distance between the wheel sensor

and sensor rotor is too large and the sensor pulse cannot

be recognized by the control unit.

Self-diagnosis results

RR RH SENSOR-2

RR LH SENSOR-2

FR RH SENSOR-2

FR LH SENSOR-2