Infiniti G35 (V35) Sedan. Manual - part 986

PB-10

< ON-VEHICLE REPAIR >

PARKING BRAKE SHOE

b.

Using suitable tool, rotate adjuster (1) in direction (B) to retract

and loosen brake shoe.

4.

Remove anti-rattle pins, retainers, anti-rattle springs, and return

spring, adjuster spring.

CAUTION:

Never drop the removed parts.

5.

Remove parking brake shoes, adjuster assembly, and toggle

lever.

CAUTION:

• The parking brake shoes for the front wheels are made of

different materials from those for the rear wheels. Never

misidentify them when removing.

• Never drop the removed parts.

6.

For the removal of back plate, refer to

RAX-7, "Removal and Installation"

.

INSTALLATION

Install in the reverse order of removal.

• Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease to the back plate and brake shoe.

CAUTION:

The parking brake shoes for the front wheels are made of different materials from those for the rear

wheels. Never misidentify them when removing and replacing.

• Assemble adjusters so that threaded part is expanded when rotat-

ing it in the direction shown by arrow.

• Shorten adjuster by rotating it.

• When disassembling after, apply PBC (Poly Butyl Cuprysil) grease

or silicone-based grease to threads.

• Check brake shoe sliding surface and drum inner surface for

grease. Wipe it off if it adhere on the surfaces.

Inspection and Adjustment

INFOID:0000000000958492

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

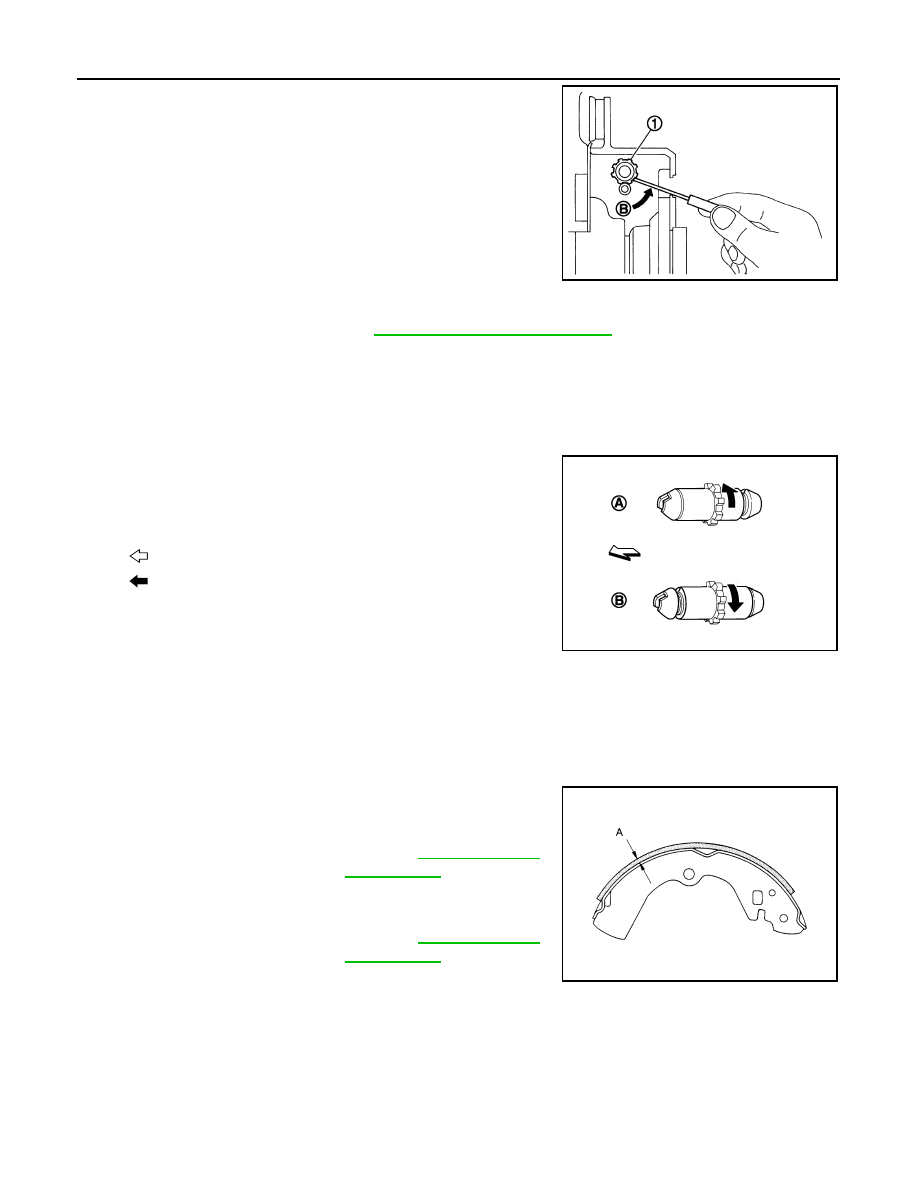

• Check thickness (A) of lining.

Drum Inner Diameter Inspection

JPFIB0007ZZ

A: For RH brake

B: For LH brake

: Vehicle front

: Adjuster expands

JPFIB0009ZZ

Standard

Standard thickness

: Refer to

Limit

Wear limit

: Refer to

SBR021A