Infiniti G35 (V35) Sedan. Manual - part 979

MWI

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-143

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

M

B

N

A

O

P

If No CAN Communication Is Available With BCM

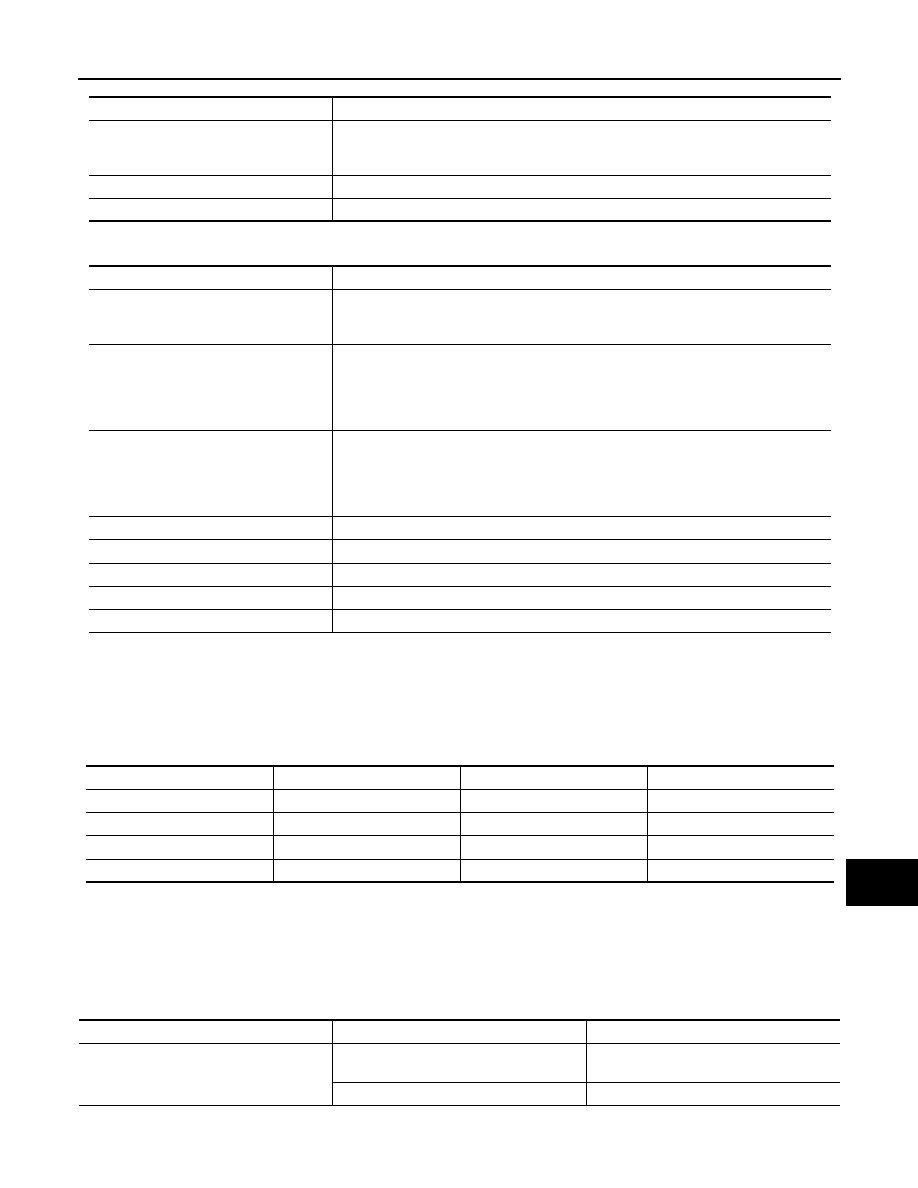

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

Control part

Fail-safe operation

Cooling fan

• Outputs the pulse duty signal (PWM signal) 100% when the ignition switch is turned

ON

• Outputs the pulse duty signal (PWM signal) 0% when the ignition switch is turned OFF

A/C compressor

A/C relay OFF

Alternator

Outputs the power generation command signal (PWM signal) 0%

Control part

Fail-safe operation

Headlamp

• Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high relay OFF

• Parking lamps

• License plate lamps

• Side maker lamps

• Illuminations

• Tail lamps

• Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper

• The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

• The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Front fog lamps

Front fog lamp relay OFF

Horn

Horn OFF

Ignition relay

The status just before activation of fail-safe is maintained.

Starter motor

Starter control relay OFF

Steering lock unit

Steering lock relay OFF

DTC

Ignition switch

Ignition relay

Tail lamp relay

—

ON

ON

—

—

OFF

OFF

—

B2098: IGN RELAY ON

OFF

ON

ON (10 minutes)

B2099: IGN RELAY OFF

ON

OFF

—

Ignition switch

Front wiper switch

Auto stop signal

ON

OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON

The signal does not change for 10 seconds.