Infiniti G35 (V35) Sedan. Manual - part 308

CL-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

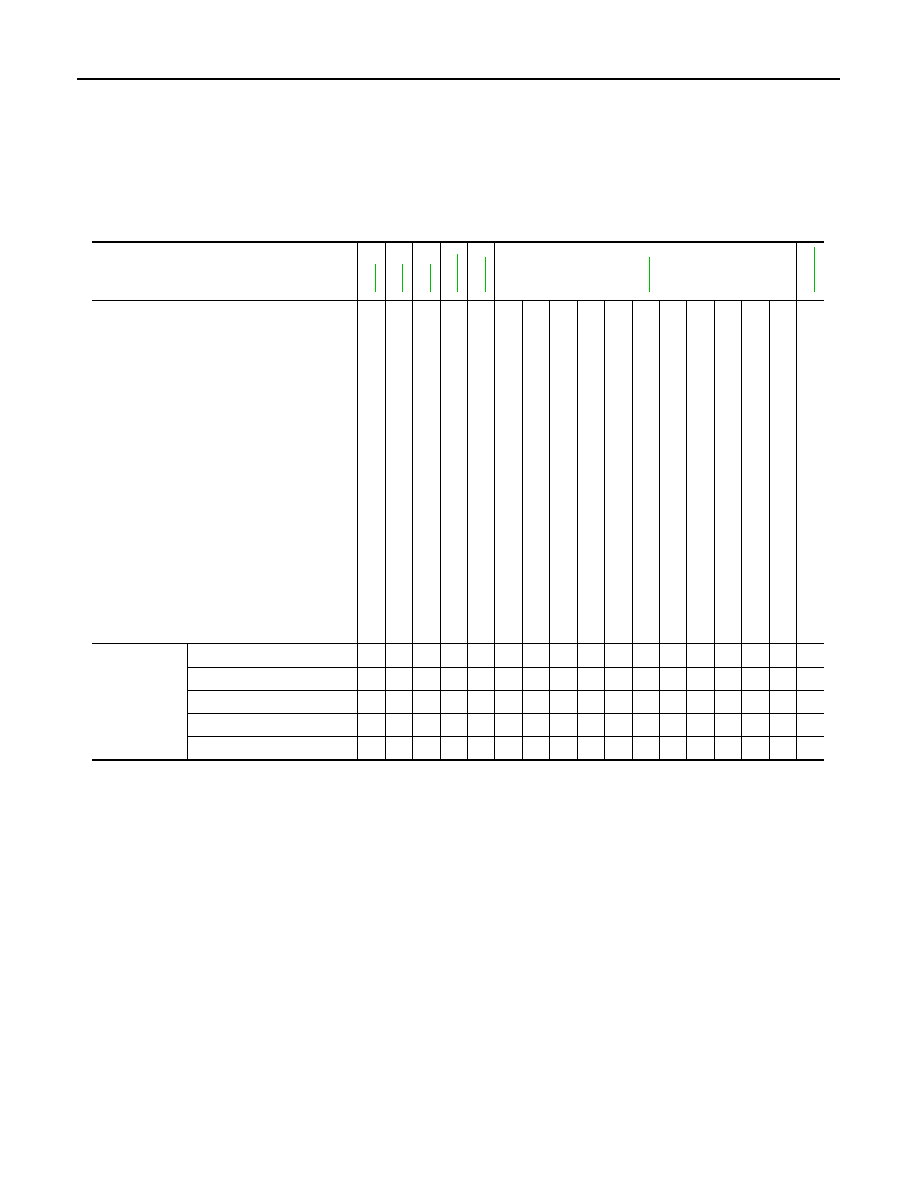

NVH Troubleshooting Chart

INFOID:0000000000956919

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference

SUSPECTED PARTS (Possible cause)

CLUTCH P

E

DAL (I

ns

pe

cti

o

n

a

nd

ad

jus

tm

e

n

t)

CLUTCH LINE (A

ir in line)

MAS

T

ER CYLINDER PIS

T

ON CUP (Damaged)

ENGINE MOU

N

TING (Loose)

CSC (Con

ce

nt

ric

Sla

v

e

Cy

lin

de

r) (W

orn

, di

rty

or

da

ma

ge

d)

CLUTCH DISC (Out

of

true)

CLUTCH DISC (Runou

t i

s

ex

ce

ssi

v

e

)

CLUTCH DISC (Lining

broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (W

orn

out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack

of

sp

lin

e

gre

a

s

e)

DI

APHRAGM SPRI

N

G (Dam

ag

ed

)

DIAPHRAGM

SPRING (Ou

t of

ti

p a

lig

nm

en

t)

PRESSURE P

L

A

T

E (Di

s

torti

on)

FL

YWHEE

L

(Distortion)

Symptom

Clutch grabs/chatters

1

2

2

2

2

2

Clutch pedal spongy

1

2

2

Clutch noisy

1

Clutch slips

1

2

2

3

4

5

Clutch does not disengage

1

2

3

4

4

4

4

4

4

4

5

5

6