Infiniti G35 (V35) Sedan. Manual - part 265

REPAIRING HIGH STRENGTH STEEL

BRM-29

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

BRM

N

O

P

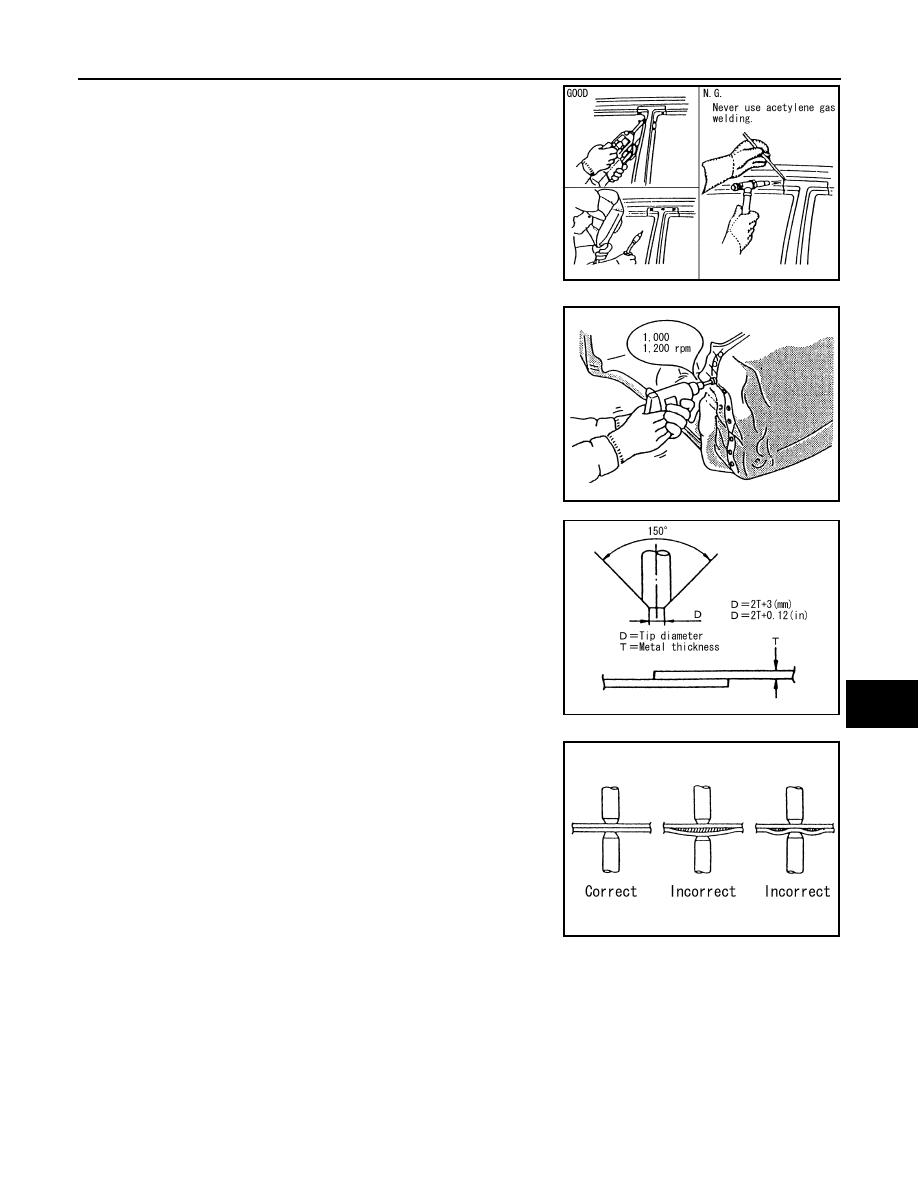

• When welding HSS panels, use spot welding whenever possi-

ble in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use MIG. welding. Do not use

gas (torch) for welding because it is inferior in welding

strength.

• The spot weld on HSS panels is harder than that of an ordi-

nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

2.

Precautions in spot welding HSS

This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according to

the metal thickness.

• The panel surfaces must fit flush to each other, leaving no

gaps.

PIIA0144E

PIIA0145E

PIIA0146E

PIIA0147E