Content .. 1332 1333 1334 1335 ..

Infiniti G35 (V35) Sedan. Manual - part 1334

TM-28

< REMOVAL AND INSTALLATION >

[6MT: FS6R31A]

TRANSMISSION ASSEMBLY

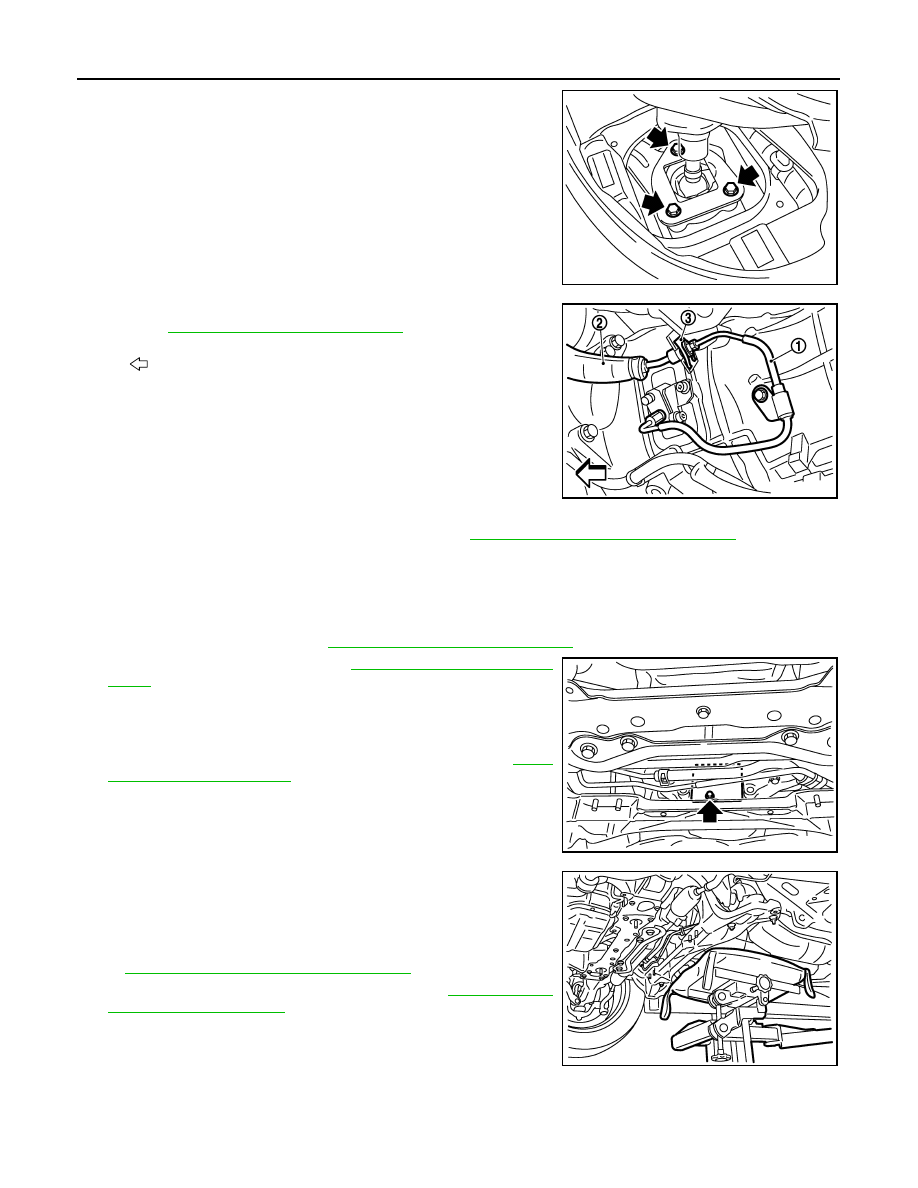

g.

Remove guide plate mounting bolts and then remove control

lever assembly and control lever spring from control lever hous-

ing.

CAUTION:

Restrain guide plate while doing this because there is a

danger control lever assembly will fly out of control lever

housing.

7.

Remove clutch tube (1), clutch hose (2), and lock plate (3).

Refer to

CL-13, "Removal and Installation"

CAUTION:

• Keep painted surface on the body or other parts free of

clutch fluid. If it spills, wipe up immediately and wash the

affected area with water.

• Do not depress clutch pedal during removal procedure.

NOTE:

Insert a suitable plug into clutch hose and CSC (Concentric

Slave Cylinder) tube after removing clutch tube.

8.

Remove crankshaft position sensor (POS). Refer to

EM-114, "Disassembly and Assembly"

CAUTION:

• Handle carefully to avoid dropping and shocks.

• Do not disassemble.

• Do not allow metal powder to adhere to magnetic part at sensor tip.

• Do not place sensors in a location where they are exposed to magnetism.

9.

Remove starter motor. Refer to

STR-16, "Removal and Installation"

.

10. Remove rear plate cover. Refer to

.

11. Disconnect park/neutral position (PNP) switch harness connec-

tor.

12. Disconnect heated oxygen sensor 2 (bank 1) and heated oxy-

gen sensor 2 (bank 2) harness connectors. Refer to

13. Remove harness brackets.

14. Set a suitable jack to the transmission assembly.

CAUTION:

When setting a suitable jack, be careful so that it does not

contact with the switch.

15. Remove engine mounting insulator (rear) mounting nuts. Refer

EM-77, "2WD : Removal and Installation"

.

16. Remove rear engine mounting member. Refer to

.

17. Remove engine and transmission mounting bolts with power

tool.

18. Lower a suitable jack to the position where the back-up lamp

switch harness connector can be disconnect. Then disconnect back-up lamp switch harness connector.

19. Remove transmission assembly from the vehicle.

CAUTION:

JPDIC0022ZZ

: Vehicle front

JPDIC0026ZZ

JPDIC0024ZZ

JPDIC0023ZZ