Infiniti FX35 / FX45. Manual - part 948

DTC INDEX

TF-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

TF

N

O

P

SERVICE INFORMATION

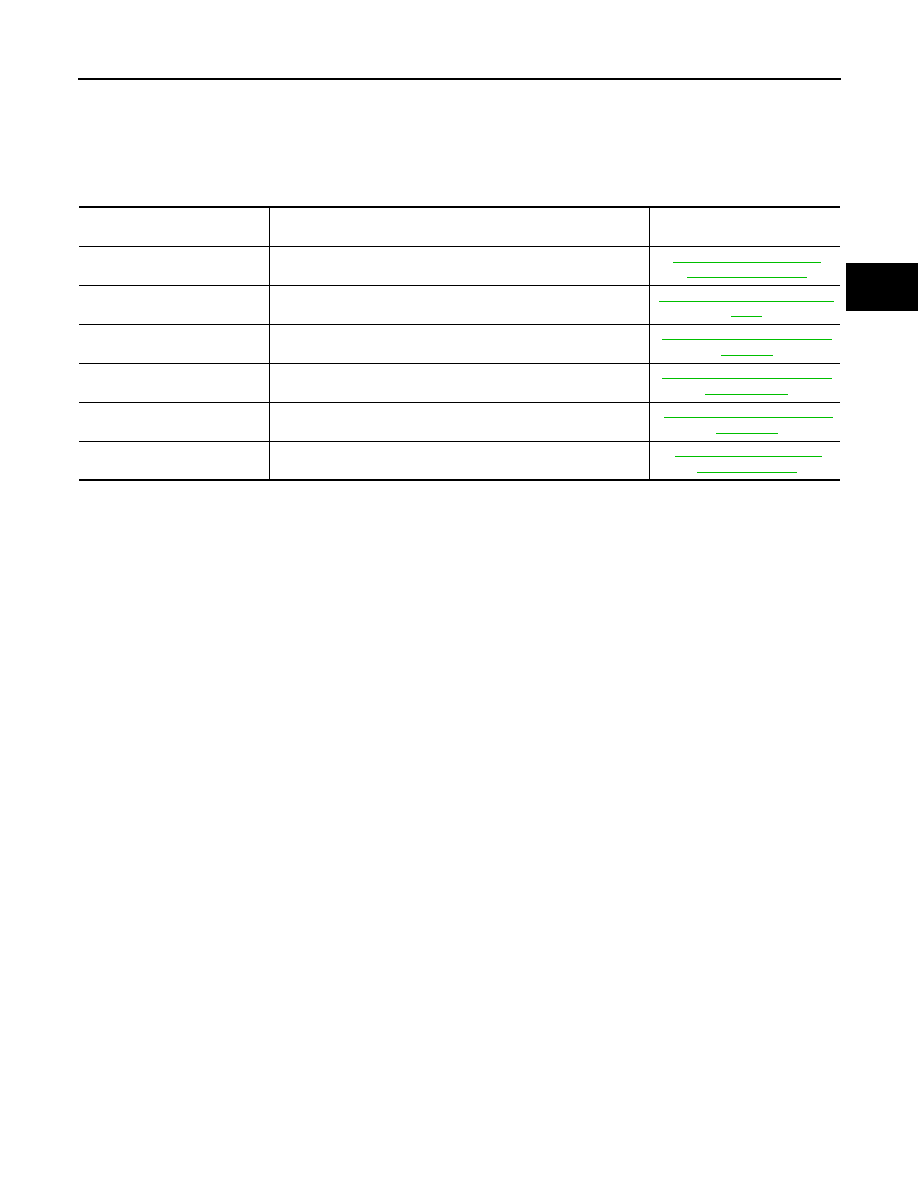

DTC INDEX

C1201-C1210, U1000

INFOID:0000000001534985

DTC

Items

(CONSULT-III screen terms)

Reference

C1201

CONTROLLER FAILURE

C1203

ABS SYSTEM

C1204

4WD SOLENOID

C1205

4WD ACTUATOR RLY

C1210

ENGINE SIGNAL 1

U1000

CAN COMM CIRCUIT