Infiniti FX35 / FX45. Manual - part 846

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

M

A

B

PG

N

O

P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

System Description

INFOID:0000000001328870

• IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It controls integrated relay via IPDM E/R control circuit.

• IPDM E/R-integrated control circuit performs ON-OFF operation of relay, CAN communication control, oil

pressure switch signal, and hood switch signal reception, etc.

• It controls operation of each electrical part via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R-integrated relays can be removed.

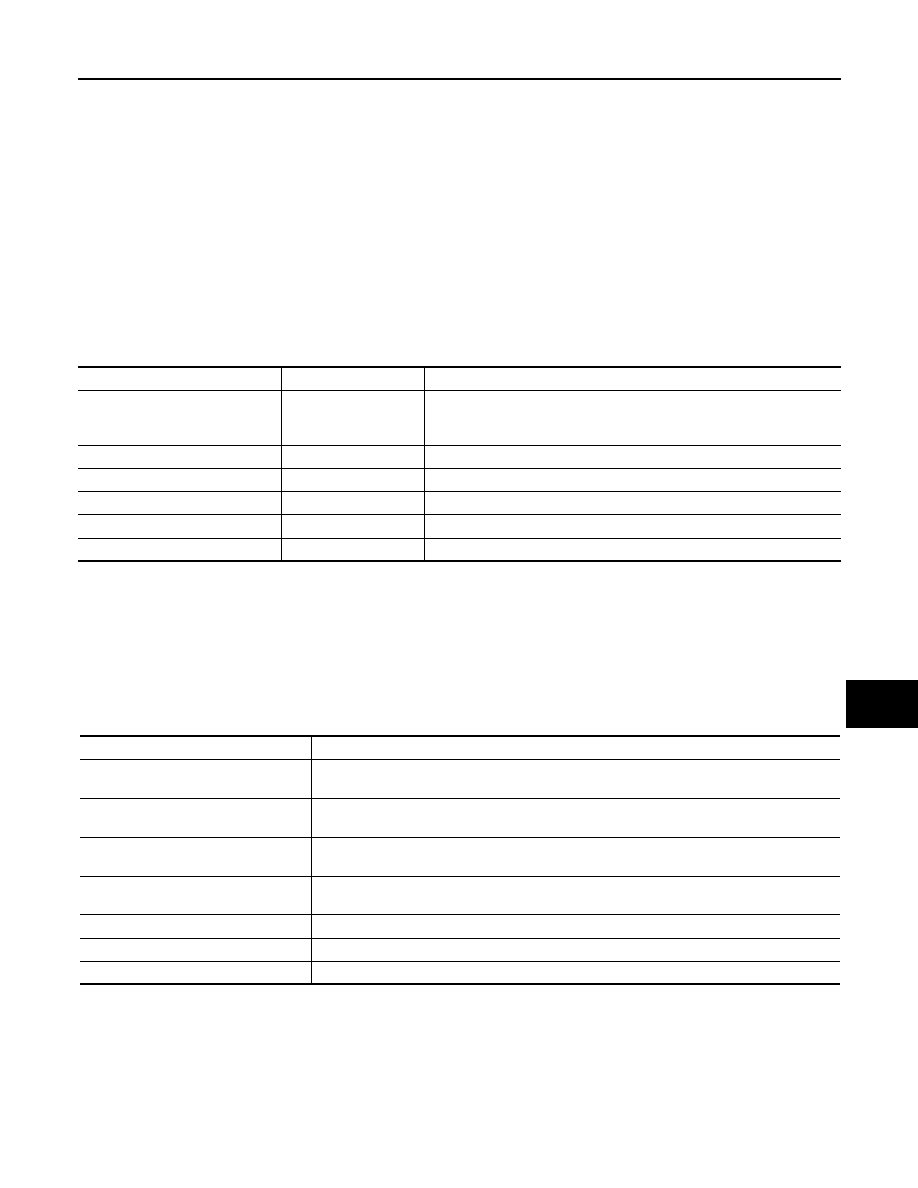

SYSTEMS CONTROLLED BY IPDM E/R

IPDM E/R receives a request signal from each control unit with CAN communication. It controls each system.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN-L line, CAN-H

line), it is possible to transmit maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

Fail- Safe Control

• When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control. After

CAN communication recovers normally, it also returns to normal control.

• Operation of control parts by IPDM E/R during fail-safe mode is as follows:

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1.

CAN communication status

• CAN communication is normally performed with other control units.

• Individual unit control by IPDM E/R is normally performed.

• When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2.

Sleep waiting status

• Process to stop CAN communication is activated.

Control system

Transmit control unit

Control part

Lamp control

BCM

• Headlamps (HI, LO)

• Front fog lamps

• Parking, license plate, side marker and tail lamps

Wiper control

BCM

Front wipers

Rear window defogger control

BCM

Rear window defogger

A/C compressor control

ECM

A/C compressor (magnet clutch)

Cooling fan control

ECM

Cooling fan

Horn control

BCM

Horn

Controlled system

Fail-safe mode

Headlamp

• With the ignition switch ON, the headlamp (low) is ON.

• With the ignition switch OFF, the headlamp (low) is OFF.

Parking, license plate side marker, and

tail lamps

• With the ignition switch ON, the parking, license plate, side marker and tail lamps is ON.

• With the ignition switch OFF, the parking, license plate, side marker and tail lamps is OFF.

Cooling fan

• With the ignition switch ON, the cooling fan HI operates.

• With the ignition switch OFF, the cooling fan stops.

Front wiper

Until the ignition switch is turned OFF, the front wiper LO and HI remains in the same status

it was in just before fail-safe control was initiated.

Rear window defogger

Rear window defogger relay OFF

A/C compressor

A/C compressor OFF

Front fog lamps

Front fog lamp relay OFF