Infiniti FX35 / FX45. Manual - part 837

MA-28

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

3.

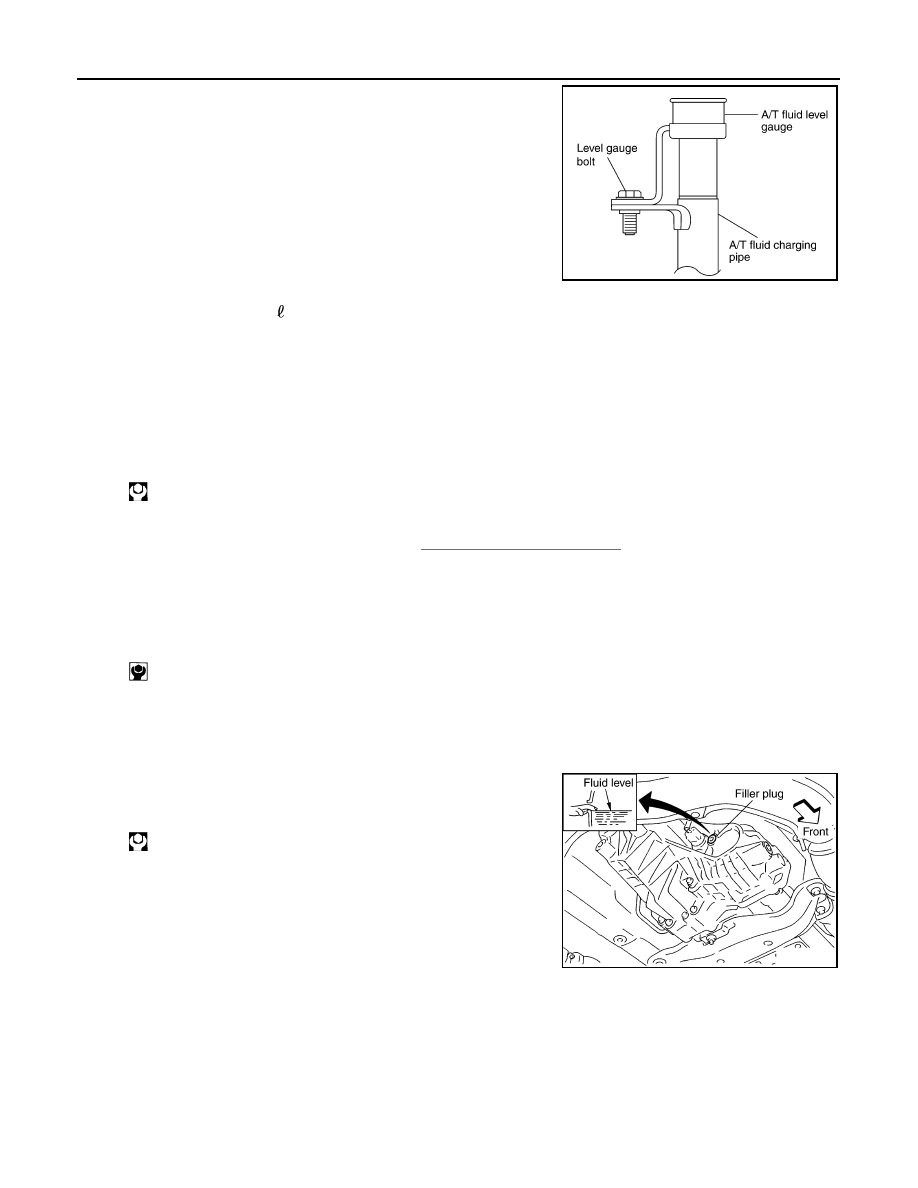

Loosen the level gauge bolt.

4.

Drain ATF from drain plug and refill with new ATF. Always refill

same volume with drained ATF.

• To replace the ATF, pour in new ATF at the A/T fluid charging

pipe with the engine idling, at the same time drain the old ATF

from the radiator cooler hose return side.

• When the color of the ATF coming out is almost same as the

color of the new ATF, the replacement is complete. The

amount of new ATF to use should be 30 to 50% increase of

the stipulated amount.

CAUTION:

• Use only Genuine NISSAN Matic J ATF. Do not mix with other ATF.

• Using ATF other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and A/

T durability, and may damage the A/T, which is not covered by the warranty.

• When filling ATF, take care not to scatter heat generating parts such as exhaust.

• Do not reuse drain plug gasket.

5.

Run engine at idle speed for 5 minutes.

6.

Check A/T fluid level and condition. Refer to

. If ATF is still dirty, repeat step

2. through 5.

7.

Install the removed A/T fluid level gauge into A/T fluid charging pipe.

8.

Tighten the level gauge bolt.

Checking Transfer Fluid

INFOID:0000000001328921

Check for fluid leakage and fluid level.

CAUTION:

Never start engine while checking fluid level.

Changing Transfer Fluid

INFOID:0000000001328922

CAUTION:

When draining fluid, protect exhaust tube flange with cover.

1.

Drain fluid from drain plug and refill with new gear fluid.

ATF: Genuine NISSAN Matic J ATF

Fluid capacity: 10.3 (10-7/8 US qt, 9-1/8 lmp qt)

Drain plug:

: 34 N·m (3.5 kg-m, 25 ft-lb)

Level gauge bolt:

: 5.1 N·m (0.52 kg-m, 45 in-lb)

SCIA4896E

Filler plug:

: 35 N·m (3.6 kg-m, 26 ft-lb)

SDIA2028E