Infiniti FX35 / FX45. Manual - part 834

MA-16

< SERVICE INFORMATION >

ENGINE MAINTENANCE (VQ35DE ENGINE)

Engine oil capacity (Approximate):

Unit:

(US qt, lmp qt)

CAUTION:

• When filling engine oil, do not pull out oil level gauge.

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

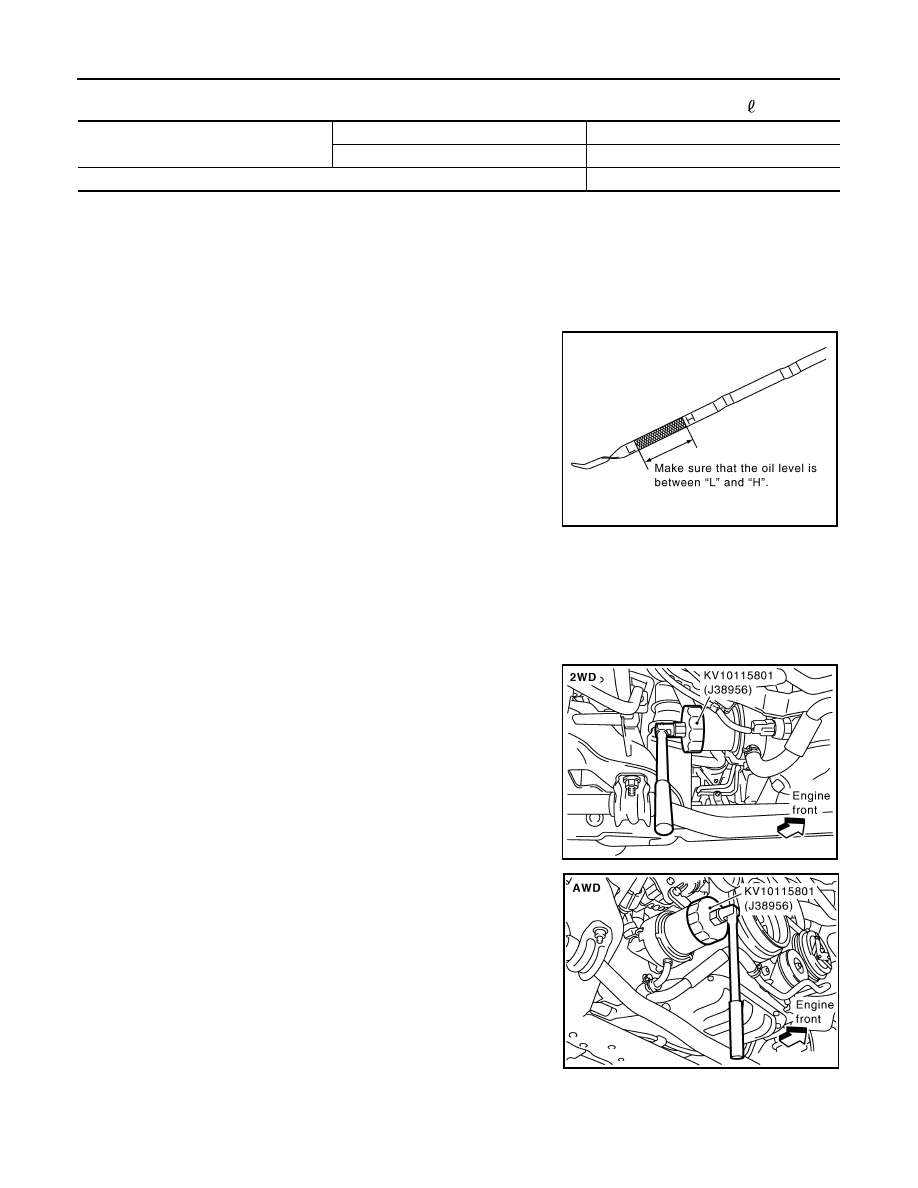

tions for reference only.

• Always use oil level gauge to determine the proper amount of engine oil in engine.

8.

Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

9.

Stop the engine and wait for 10 minutes.

10. Check the engine oil level.

Changing Oil Filter

INFOID:0000000001328906

REMOVAL

WARNING:

Be careful not to get burned when the engine and engine oil may be hot.

1.

Remove front engine undercover with power tool.

2.

Using oil filter wrench (SST), remove oil filter.

CAUTION:

• Oil filter is provided with relief valve. Use genuine NISSAN

oil filter or equivalent.

• When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to drive belts.

• Completely wipe off any engine oil that adheres to engine

and vehicle.

INSTALLATION

1.

Remove foreign materials adhering to oil filter installation surface.

Drain and refill

With oil filter change

4.7 (5, 4-1/8)

Without oil filter change

4.4 (4-5/8, 3-7/8)

Dry engine (Overhaul)

5.4 (5-3/4, 4-3/4)

PBIC3101E

SBIA0454E

SBIA0455E