Infiniti FX35 / FX45. Manual - part 694

FAX-12

< SERVICE INFORMATION >

[AWD]

FRONT WHEEL HUB AND KNUCKLE

5.

Remove cotter pin, then remove lock nut from drive shaft.

6.

Remove steering outer socket and cotter pin at steering knuckle, then loosen mounting nut.

7.

Use a ball joint remover (SST) to remove steering outer socket

from steering knuckle. Be careful not to damage ball joint boot.

CAUTION:

To prevent damage to threads and to prevent ball joint

remover (SST) from coming off suddenly, temporarily

tighten mounting nut.

8.

Using a puller (suitable tool), remove wheel hub and bearing assembly from drive shaft.

NOTE:

• When removing wheel hub and bearing assembly, do not apply an excessive angle to drive shaft joint.

Also be careful not to excessively extend slide joint.

• Do not hang over drive shaft with out support.

9.

Remove wheel hub and bearing assembly fixing bolt.

10. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

11. Remove strut assembly and steering knuckle fixing bolts and nuts.

12. Remove transverse link and steering knuckle fixing bolt and nut.

13. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each parts, replace if necessary.

Ball Joint Inspection

Check for boot breakage, axial looseness, and torque of transverse link and steering outer socket ball joint.

Refer to

INSTALLATION

CAUTION:

Be sure to replace the new differential side oil seal every removal of drive shaft. Refer to

.

• Refer to "Removal and Installation"for tightening torque. Install in the reverse order of removal.

NOTE:

Refer to component parts location and do not reuse non-reusable parts.

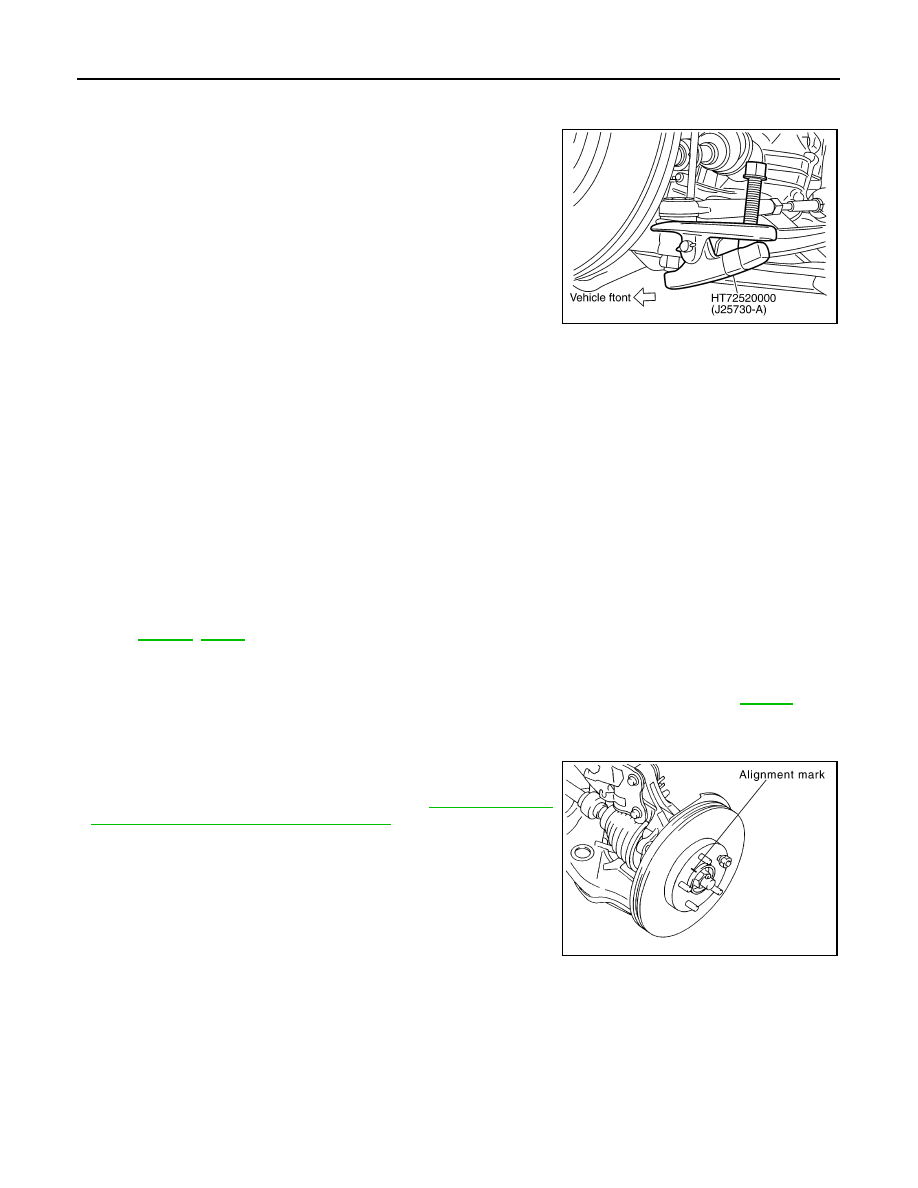

• To assemble disc rotor and wheel hub and bearing assembly, align

the marks.

(When not using the alignment mark, refer to

and Installation of Brake Caliper Assembly"

.)

SGIA0488E

SDIA1480E