Infiniti FX35 / FX45. Manual - part 686

CYLINDER BLOCK

EM-261

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

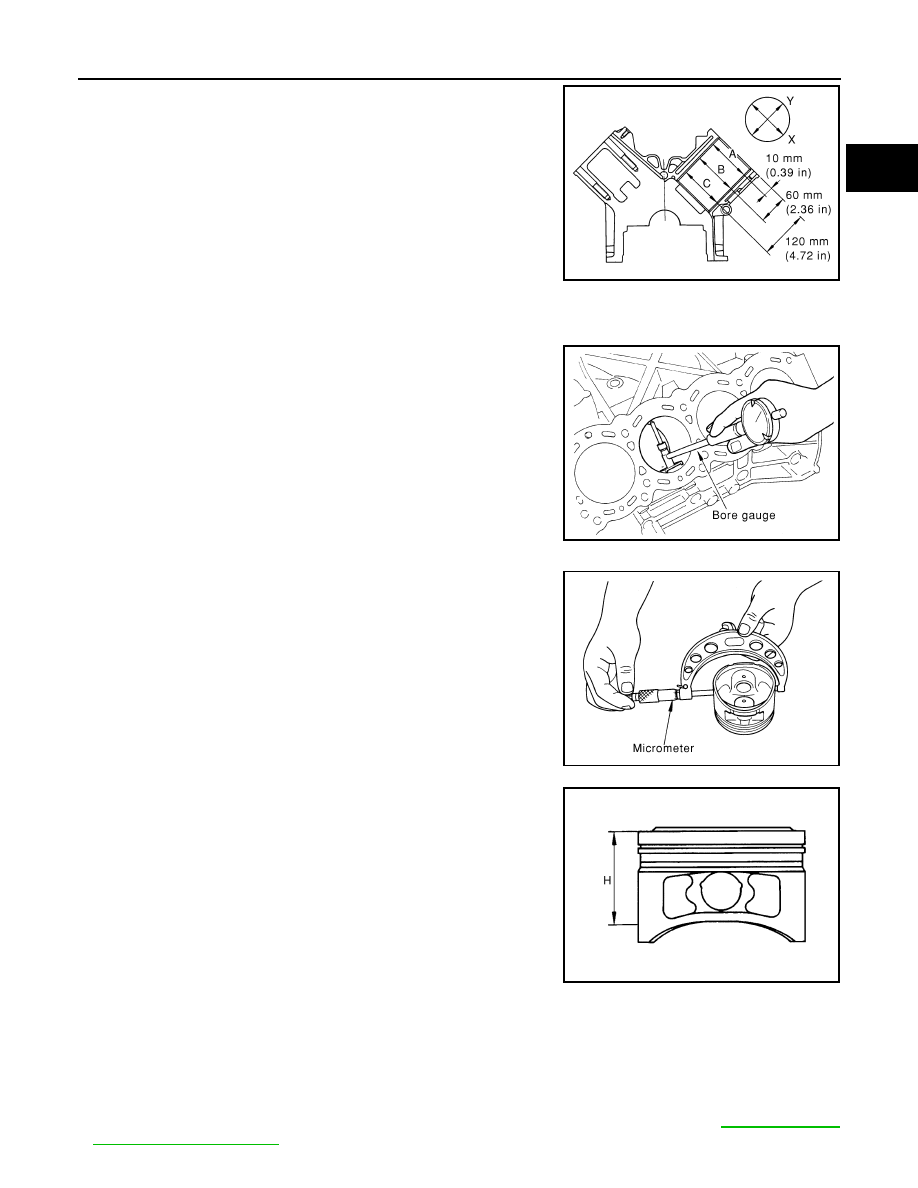

• Using bore gauge, measure cylinder bore for wear, out-of-round

and taper at six different points on each cylinder. (“X” and “Y” direc-

tions at “A”, “B” and “C”) (“Y” is in longitudinal direction of engine)

• If the measured value exceeds the limit, or if there are scratches

and/or seizure on the cylinder inner wall, hone or re-bore the inner

wall.

• Oversize piston is provided. When using oversize piston, re-bore

cylinder so that the clearance of the piston-to-cylinder bore satis-

fies the standard.

CAUTION:

When using oversize piston, use oversize pistons for all cylin-

ders with oversize piston rings.

Piston Skirt Diameter

• Measure the outer diameter of piston skirt with micrometer.

• Measure point “H” (Distance from the top): 42 mm (1.65 in)

Piston to Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter (direction “X”, position “B”).

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter).

• If the calculated value exceeds the limit, replace piston and piston pin assembly. Refer to

.

Standard inner diameter:

93.000 - 93.030 mm (3.6614 - 3.6626 in)

Wear limit:

0.2 mm (0.008 in)

Out-of-round (Difference between “X” and “Y”):

0.015 mm (0.0006 in)

Taper limit (Difference between “A” and “C”):

0.01 mm (0.0004 in)

Oversize (OS)

: 0.2 mm (0.008 in)

PBIC0123E

PBIC0124E

Standard

: 92.980 - 93.010 mm (3.6606 - 3.6618 in)

PBIC0125E

PBIC0126E

Standard

: 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit

: 0.08 mm (0.0031 in)