Infiniti FX35 / FX45. Manual - part 668

SPARK PLUG (PLATINUM-TIPPED TYPE)

EM-189

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

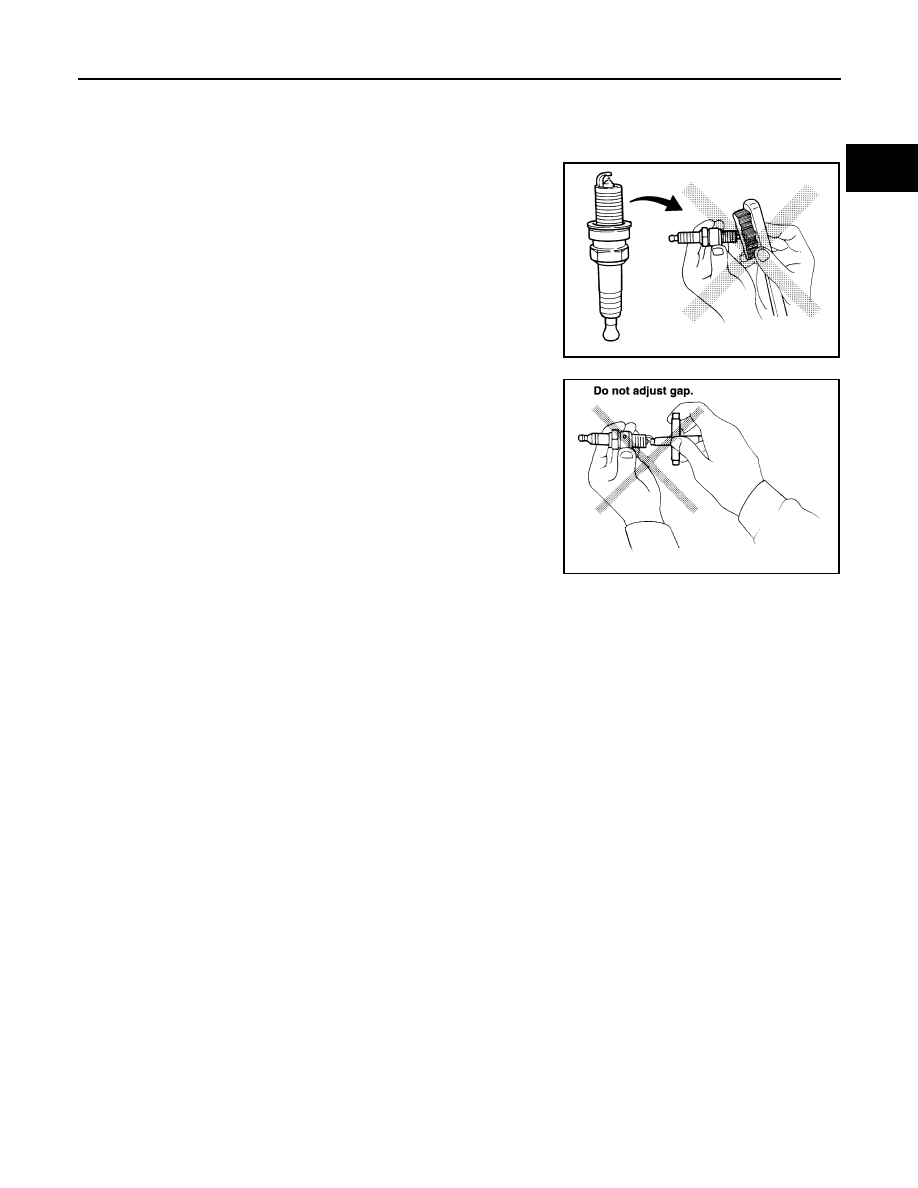

CAUTION:

• Do not drop or shock spark plug.

• Do not use wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be

used.

• Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Install in the reverse order of removal.

Gap (Nominal)

: 1.1 mm (0.043 in)

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2

, 85 psi)

Cleaning time:

Less than 20 seconds

SMA773C

SMA806CA