Infiniti FX35 / FX45. Manual - part 642

CAMSHAFT

EM-85

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

6.

Remove valve lifter.

• Identify installation positions, and store them without mixing them up.

7.

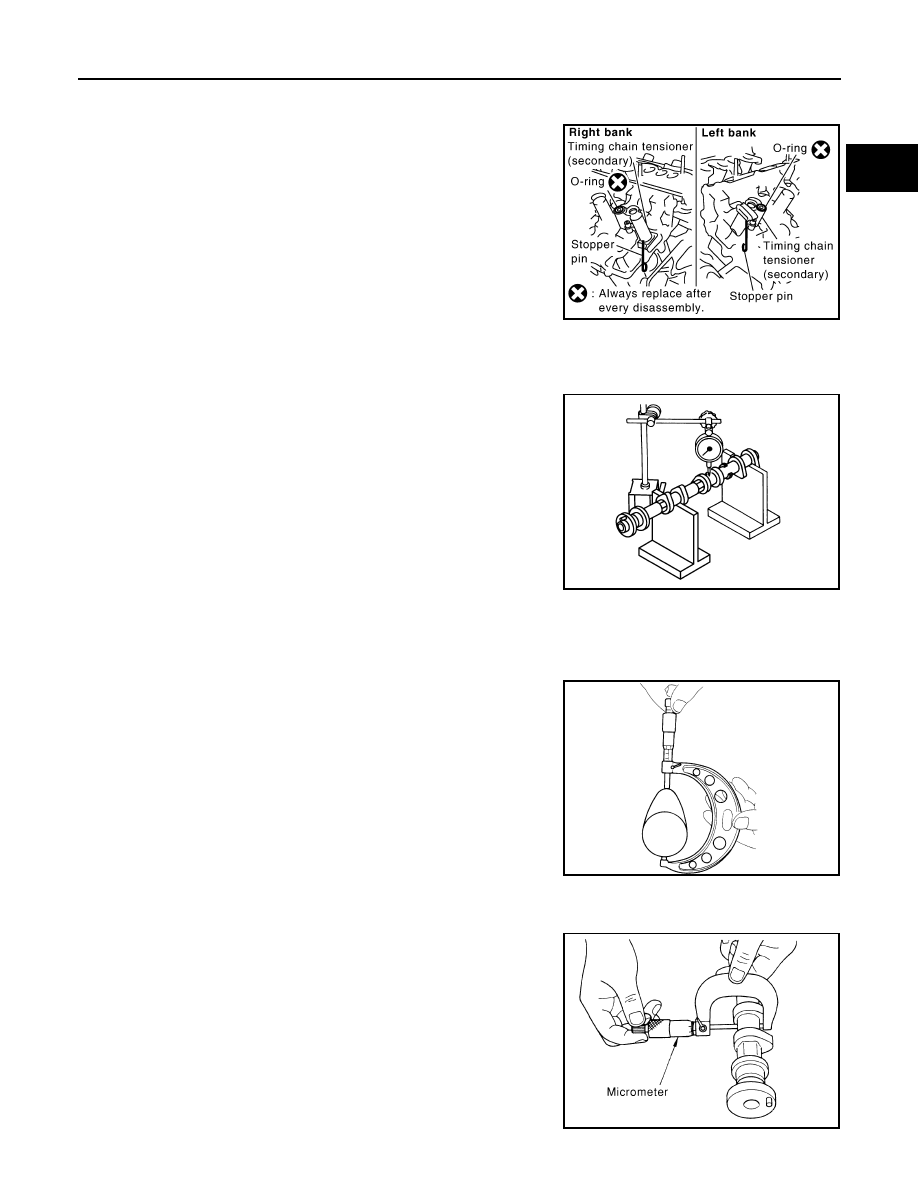

Remove timing chain tensioner (secondary) from cylinder head.

• Remove timing chain tensioner (secondary) with its stopper

pin attached.

NOTE:

Stopper pin was attached when timing chain (secondary) was

removed.

INSPECTION AFTER REMOVAL

Camshaft Runout

1.

Put V-block on precise flat table, and support No. 2 and 4 jour-

nals of camshaft.

CAUTION:

Do not support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

three locations.

2.

Set a dial indicator vertically to No. 3 journal.

3.

Turn camshaft to one direction with hands, and measure the

camshaft runout on a dial indicator. (Total indicator reading)

4.

If it exceeds the limit, replace camshaft.

Camshaft Cam Height

1.

Measure the camshaft cam height with a micrometer.

2.

If wear exceeds the limit, replace camshaft.

Camshaft Journal Oil Clearance

CAMSHAFT JOURNAL DIAMETER

• Measure the outer diameter of camshaft journal with a micrometer.

PBIC2111E

Standard

: Less than 0.02 mm (0.0008 in)

Limit

: 0.05 mm (0.0020 in)

PBIC0929E

Standard cam height (intake and exhaust)

: 44.865 - 45.055 mm (1.7663 - 1.7738 in)

Cam wear limit

: 0.2 mm (0.008 in)

EMQ0072D

Standard:

No. 1

: 25.935 - 25.955 mm (1.0211 - 1.0218 in)

No. 2, 3, 4

: 23.445 - 23.465 mm (0.9230 - 0.9238 in)

PBIC0040E