Infiniti FX35 / FX45. Manual - part 548

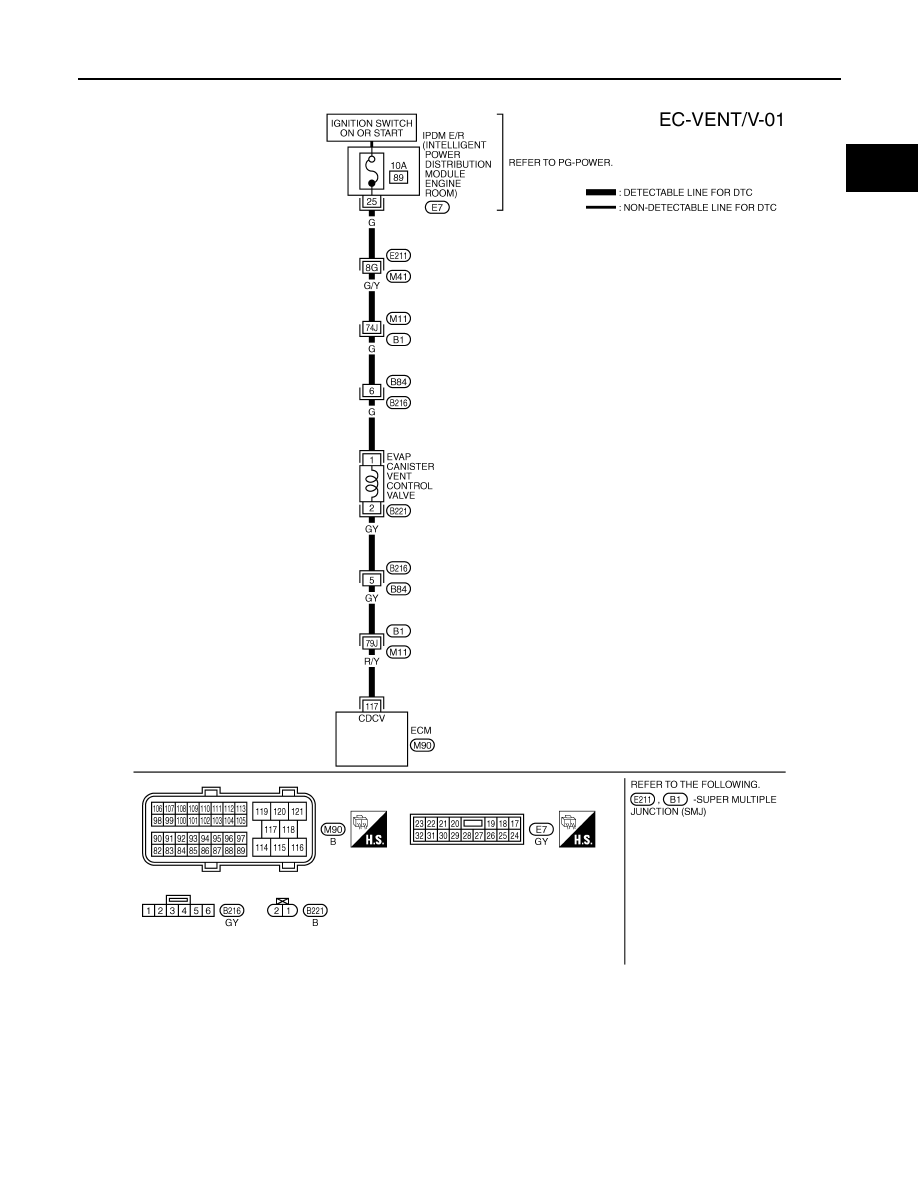

DTC P0448 EVAP CANISTER VENT CONTROL VALVE

EC-953

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Wiring Diagram

INFOID:0000000001326793

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TBWM1339E