Infiniti FX35 / FX45. Manual - part 536

DTC P0327, P0328, P0332, P0333 KS

EC-905

< SERVICE INFORMATION >

[VK45DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

OK or NG

OK

>> GO TO 6.

NG

>> Repair or replace ground connections.

6.

CHECK KNOCK SENSOR SHIELD CIRCUIT FOR OPEN AND SHORT

1.

Disconnect knock sensor harness connector.

2.

Check harness continuity between knock sensor terminal 2 and ground. Refer to Wiring Diagram.

3.

Also check harness for short to power.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F40, F241

• Harness connectors F102, M82

• Harness for open or short between knock sensor terminal 2 and ground

>> Repair open circuit or short to power in harness or connectors.

8.

CHECK INTERMITTENT INCIDENT

>> INSPECTION END

Component Inspection

INFOID:0000000001326736

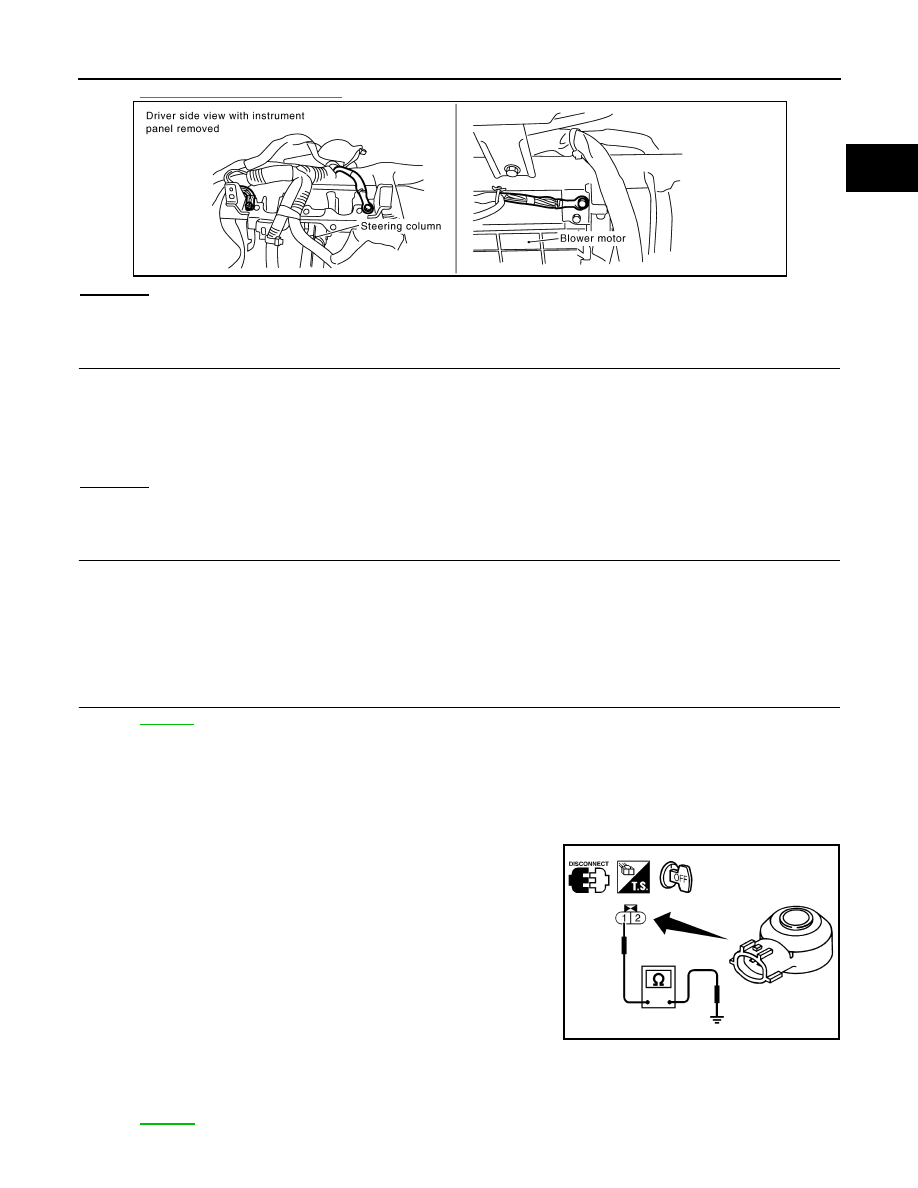

KNOCK SENSOR

Check resistance between knock sensor terminal 1 and ground.

NOTE:

It is necessary to use an ohmmeter which can measure more

than 10 M

Ω

.

CAUTION:

Do not use any knock sensors that have been dropped or phys-

ically damaged. Use only new ones.

Removal and Installation

INFOID:0000000001326737

KNOCK SENSOR

.

PBIB2195E

Continuity should exist.

Resistance: Approximately 532 - 588 k

Ω

[at 20

°

C (68

°

F)]

SEF111Y