Infiniti FX35 / FX45. Manual - part 382

DTC P0172, P0175 FUEL INJECTION SYSTEM FUNCTION

EC-289

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis Procedure

INFOID:0000000001326108

1.

CHECK EXHAUST GAS LEAK

1.

Start engine and run it at idle.

2.

Listen for an exhaust gas leak before three way catalyst 1.

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace.

2.

CHECK FOR INTAKE AIR LEAK

TER-

MI-

NAL

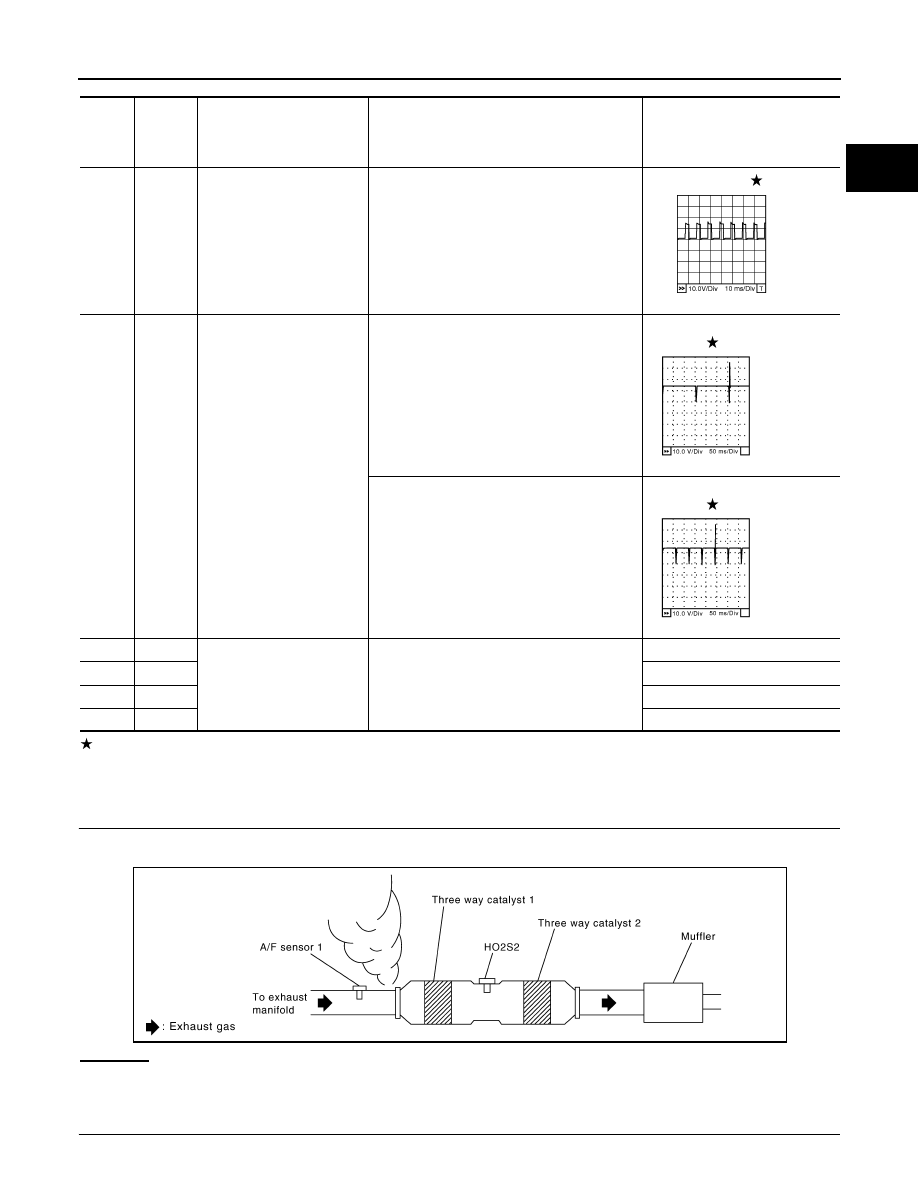

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

24

L

A/F sensor 1 heater

(bank 2)

[Engine is running]

• Warm-up condition

• Idle speed

Approximately 5V

40

41

42

LG

B

P

Fuel injector No. 6

Fuel injector No. 4

Fuel injector No. 2

[Engine is running]

• Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

BATTERY VOLTAGE

(11 - 14V)

[Engine is running]

• Warm-up condition

• Engine speed: 2,000 rpm

BATTERY VOLTAGE

(11 - 14V)

57

G

A/F sensor 1 (bank 2)

[Engine is running]

• Warm-up condition

• Idle speed

Approximately 2.6V

58

Y

Approximately 2.3V

76

P

Approximately 3.1V

77

BR

Approximately 2.3V

PBIB1584E

SEC984C

SEC985C

PBIB1922E