Infiniti FX35 / FX45. Manual - part 320

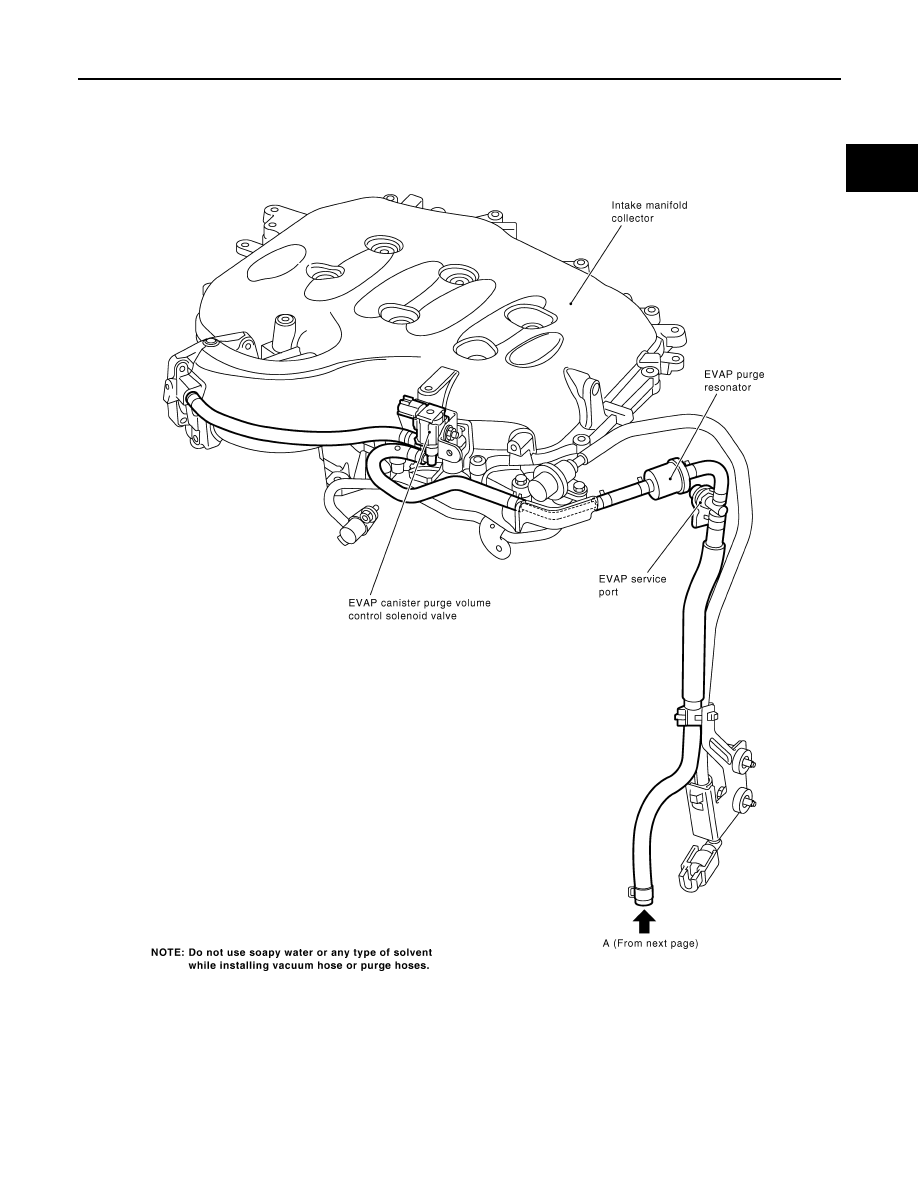

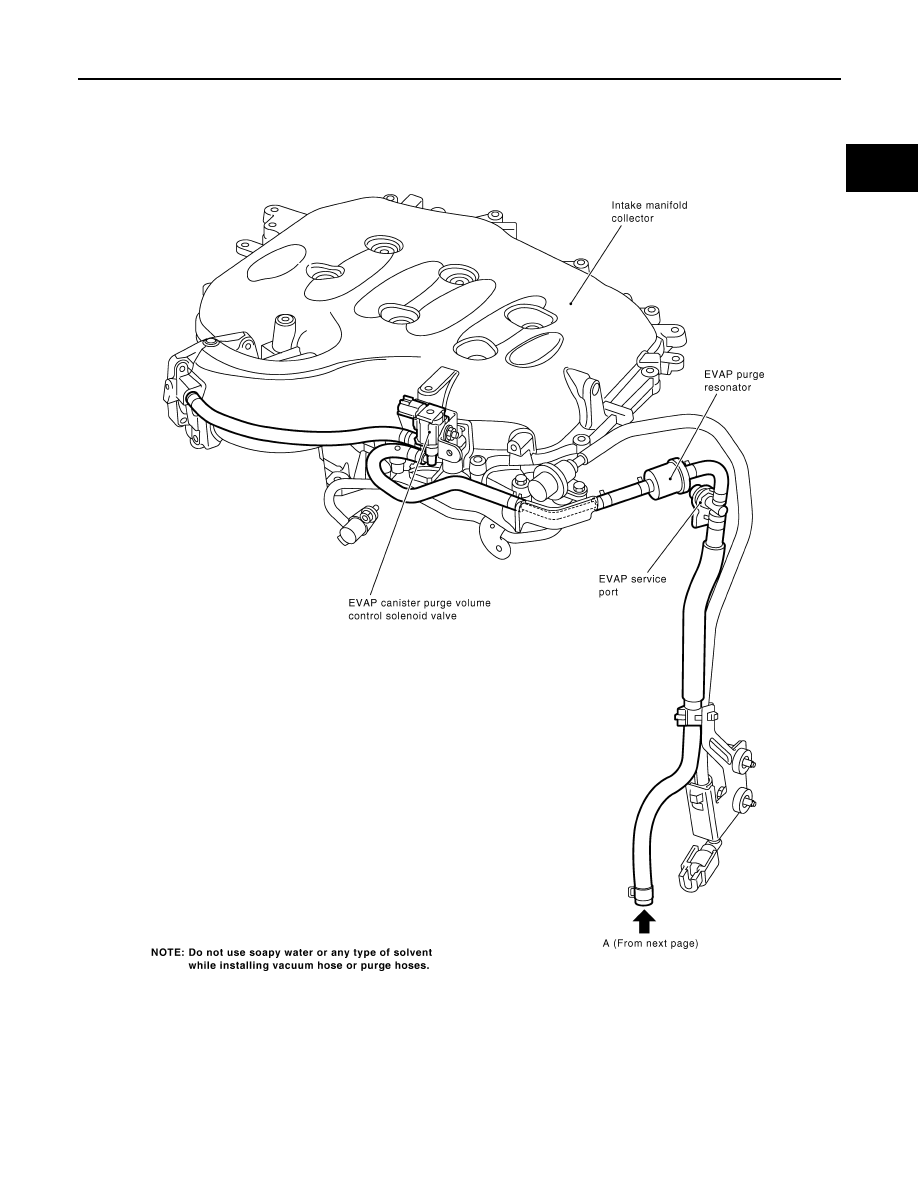

EVAPORATIVE EMISSION SYSTEM

EC-41

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

EVAPORATIVE EMISSION LINE DRAWING

PBIB2096E

|

|

|

EVAPORATIVE EMISSION SYSTEM EC-41 < SERVICE INFORMATION > [VQ35DE] C D E F G H I J K L M A EC N P O EVAPORATIVE EMISSION LINE DRAWING PBIB2096E |